Now You Know Textile Dyeing Process with Ultrasonic Waves

Monday, 21 January 2019

Edit

Jamal Haider Hasib

B.Sc. in Textile Engineering

Southeast University

Cell: 01719920188

E-mail: jhhasib@gmail.com

B.Sc. in Textile Engineering

Southeast University

Cell: 01719920188

E-mail: jhhasib@gmail.com

Abstract:

Bangladesh has become a lower-middle income country due to its tremendous growth of textile industry. Bangladesh is second only to China, the world's second-largest apparel exporter of western brands. Due to competitive market; now a day’s companies always seek a cost effective production process specially in wet processing. In conventional wet processing an unbelievable amount of water consumes in each and every steps along with chemicals. At this time Nanotechnology takes places in textile sector. The first and foremost aim of this study is to reduce use of water, and chemicals in textile dyeing process using ultrasonic waves.

Background and Significance:

Color the earth beautiful and kill it with sweet poison! Color is the main attraction of any fabric. No matter how excellent its constitution, if unsuitably colored it is bound to be a failure as a commercial fabric. Manufacture and use of dyes for fabric dyeing has therefore become a massive industry today. The textile dyeing and finishing industry has created a huge pollution problem as it is one of the most chemically intensive industries on earth, and the No.1 polluter of clean water (after agriculture). More than 3600 individual textile dyes are being manufactured by the Industry today. The industry is using more than 8000 chemicals in various processes of textile manufacture extremely in dyeing and printing. The World Bank estimates that 17 to 20 percent of industrial water pollution comes from textile dyeing and finishing treatment given to fabric. Some 72 toxic chemicals have been identified in water solely from textile dyeing, 30 of which cannot be removed. This represents an appalling environmental problem for the clothing and textile manufacturers.

As I am from Bangladesh, I hope it will be easy to explain the study on this topic from Bangladesh perspective. Bangladesh is a third world developing country. The textiles and readymade garments industry in Bangladesh has been proved significantly important in the country's pursuit for export growth. Bangladesh is the first largest foreign currency earner which is more than 77% of the total export. It also contributes to poverty alleviation thorough employment especially by women's economic empowerment and worker welfare. But it is my painful duty to inform you that we have already polluted our environment.

As a result important water quality parameters of our industrial are seriously injured. Our most important rivers like Turag & Burigonga have already polluted seriously due to direct discharge of Effluent generated by textile Industry. The present world is confronted with numerous challenges of globalization.

The developing countries like Bangladesh are facing realities of fast global trade scenario. Against this back drop, there is a growing need for further development, diversification and adaptation of local product, as well as research and development of textile technology and engineering. Through utilizing & implementing effective technology with effective manpower management the cost of dyeing could be reduced to a greater extent maintaining the environment safe through properly treating the discharged water. The environment especially water & lives dependent on water could be kept safe & secured through discharging properly treated water. That’s why I wish to develop to an alternative method of dyeing process of textile materials according to the theory of ultrasonic waves. That will reduce water, auxiliary chemicals, and environmental pollution and obviously save cost of wet processing.

Research Method:

Ultrasonic waves may help me to develop an alternative method of conventional dyeing process of textile materials. Sound waves have been classified into infra-sound (up to 16Hz), audible sound (16 Hz –16000 Hz) and ultrasound; sound waves that have a frequency above approximately 16 kHz up to 106 kHz. In this world many species are using ultrasonic waves to live. Sounds in the range of 20-100 kHz are commonly used for communication and navigation by bats, dolphins, and some other species. And higher frequencies, in the range of 1-20 MHz, are used for medical ultrasound.

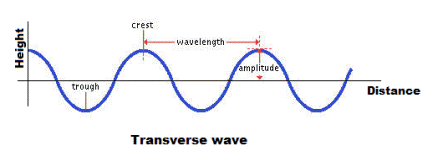

I wish to develop a process of producing colors by addition and subtractions of textile materials by ultrasonic waves. Unlike gases and liquid, in solids both longitudinal and transverse waves are transmitted. The effects of ultrasonic actually arise when sound is circulated through the medium. In liquids, longitudinal vibrations of molecules generate compressions and rarefactions, i.e., areas of high and low local pressure. The latter results in the formation of cavities, i.e., very small vapor bubbles of 500nm in size, which can collapse and cause shock waves throughout the medium.

Let see how ultrasonic waves works:

|

| Fig-1: Principle of ultrasonic wave |

|

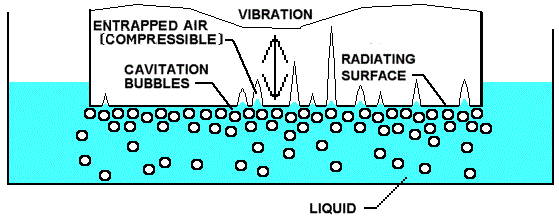

| Fig-2: Cavitations or bubbles formed in liquid by ultrasonic waves |

|

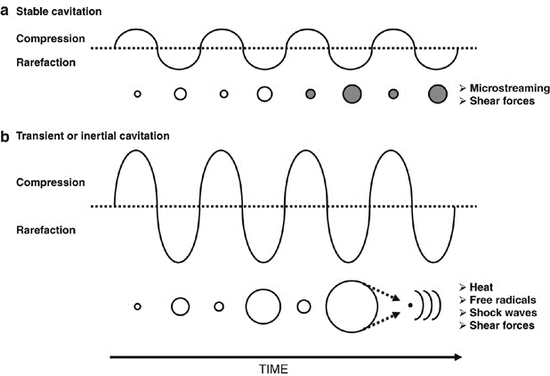

| Fig-3: Forces created during compression or rarefaction |

|

| Fig-4: Rapid movement of liquids by ultrasonic pressure |

The use of ultrasonic waves in the dyeing process can be explained as: when ultrasonic waves are absorbed in the liquid system the cavitations/bubbles created. Cavitations can liberate entrapped gases from liquid or materials like textiles, dye bath etc. (case-1). In a dye bath, vibration of waves makes compressions and rare factions. They create very small vapor bubbles of 500nm in size, which can collapse and cause shock waves throughout the bath (case-2). If the bubbles collapse in textile materials, it results the formation of a high velocity micro jet with the velocities as highly directed towards the solid surface. These micro jets can give rise to intra yarn flow, increase in the rate of the mass transfer between the intra-yarn and inter yarn pores. On the other hand, they may be carried along with the sound waves if they do not collapse immediately. This, in turn, pushes water along with the bubbles producing a flow of water called streaming away from the sound source (case-3).

Potential Benefits:

- Saving energy by dyeing at lower temperatures.

- Reduced processing times.

- Reduces the use of auxiliary chemicals.

- Enhancement of color shade.

- Reduces processing costs.

- Lesser load to the effluent.

- This process is unsophisticated and harmonized with nature.

- Optimization of Natural Dyeing Using Ultrasonic Method and Biomordant, By_N. A. Abdul Rahman, R. Tajuddin, and S. M. Tumin(International Journal of Chemical Engineering and Applications, Vol. 4, No. 3, June 2013)

- Recent developments in textile dyeing techniques, By_Rahul Guglani

- Online magazine-Textile today.

- S. Berliner, III, (Consultant in Ultrasonic Processing)

- Online magazine-fibre2fashion.

- High power ultrasound and acoustic cavitations, By_Mark Hodnett

About author:

Jamal Haider Hasib is a Textile Engineer. He has completed his graduation from Southeast University in 2013. He is currently working at a company "Friends International" as a Sr. Marketing Executive.