Yaa Latest Dry Out Washing Techniques Inwards Denim Garments (Part-4)

Sunday, 16 December 2018

Edit

Latest Dry Washing Techniques inwards Denim Garments (Part-4)

Asma Akhi

& Md.Hasibur Rahman Sunny

Dept. of Textile Engineering

Bangladesh University of Business & Technology

& Md.Hasibur Rahman Sunny

Dept. of Textile Engineering

Bangladesh University of Business & Technology

Previous Part

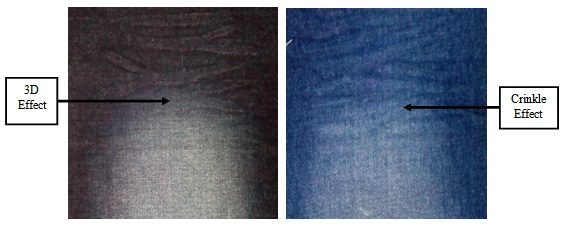

For Crinkle/3D:

Chemical: Resin (Catalyst, Silicone & PU solution)

Instrument: Pressing Crinkle Machine, Iron Machine, Dryer etc

Method:

First get got to practise spray resin on the specific expanse nosotros wishing to practise 3D effect. Without resin spray 3D consequence is non possible. Influenza A virus subtype H5N1 garment is inwards metallic plate. Resin (Formaldehyde free) beingness used for achieving 3D consequence (3 Dimensional), Rigid Look etc. This procedure tin live done yesteryear spraying or dipping the garments inwards to Resin, Catalyst, Silicone & PU solution inwards correct combination according to the cloth strength & desired consequence needed.

After application of resin solution inwards correct proportion, brand manual designing every bit needed on the thigh, hip & dorsum genu expanse to become 3Dimentional effect. After making it, it should live manually dried amongst hot press or pilus dryer & The temperature is 1900c, it deep the resin together with and thence it post to the curing to brand crinkle. Then must live cured inwards oven at correct temperature, fourth dimension every bit mentioned inwards resin production manual.

If resin non cured properly, 3D consequence volition non live permanent & tin displace peel irritation to the wearer. Highly skilled operators bespeak to execute this procedure inwards social club to become consistency & uniformity.

|

| Fig 13: 3D Sample Fig 14: Crinkle Sample |

| No. of Sample | 07 |

| M:L | 1:80 |

| Temperature | 450c,600c,700c |

| Time | 114min(All Wet Process) |

Working Recipe:

Neutral Wash:

Types of Instrument Used for Testing:

Testing & Procedure:

Following exam are done:

The GSM of cloth is ane sort of specification of cloth which is real of import for a textile engineer for agreement together with production of fabric. ‘GSM’ agency ‘Gram per foursquare meter’ that is the weight of cloth inwards gram per ane foursquare meter. By this nosotros tin compare the fabrics inwards unit of measurement expanse which is heavier together with which is lighter.

Apparatus:

Sample Weight (gm) x 100 = GSM

Sample Weight = 4.4

GSM = 4.4 x 100

= 440 gm

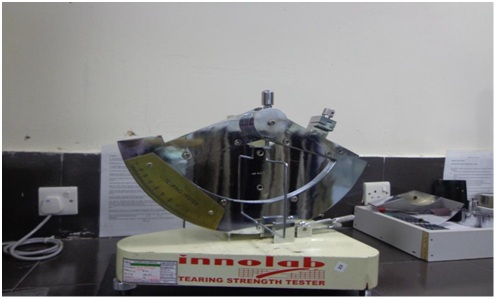

2. Tear Strength Test:

The Tear Strength of cloth is a exam that provides a mensurate of resistance to tearing. Tear strength may too live used to illustrate the anisotropy of a material. Force required to propagate an existing tear is measured. As a business office of the grooming of cloth specimen, a cutting is inwards them together with the forcefulness is required to extend the cutting is measured. Influenza A virus subtype H5N1 issue of tear strength exam is carried out together with the average is taken to decide the tear strength. Tearing strength is expressed either inwards pounds or grams.

Purpose:

To demonstrate the proper way of the garment/fabric earlier together with later processing to ensure the proper physical strength.

Method:

Calculation of Tear strength inwards Pounds ꞊ ( charge carried out yesteryear the machine × dot of indication)/100

Example: The pointer is showing the value 65% i.e. The value of violent forcefulness is 65% of the applied force(considering the applied charge is 6400g) Means the violent forcefulness is

꞊ 65% of 6400g

꞊ 65/100×6400g

꞊ 4160g the unit of measurement of the forcefulness nosotros tin converted into our required unit.

3. Count Measurement:

Count is the numerical aspect which expresses coarseness or fineness of yarn. It agency that, the yarn count refers how much a yarn is fine or course. We too tin state that the yarn count issue indicates the length of yarn inwards relation to the weight.

Neutral Wash:

- Water : 80L

- Neutral Agent (Meta Bi Sulphite) : 400gm

- Time : 11min

- Temp : 450c

- Rinse : 2min

- Water : 70L

- Desizing Agent :100gm

- Time :10min

- Temp :600c

- Rinse :4min

- Water :60L

- Enzyme Agent :200gm

- Time :35min

- Temp :450c

- Rinse : 4min

- Water : 60L

- Bleaching Agent : 400gm

- Time : 25min

- Temp : 600c & 700c

- Rinse : 2min

- Water : 60L

- Softening Agent : 200gm

- Time : 5min

- Temp : 35 0c

- Hydro-extracting & Drying : 5min & lxx 0c

Working Process:

Start the sample dying machine

↓

Run the m/c for 2 mo at temp 37⁰c amongst required H2O

↓

Drop the liquor

↓

Load the sample amongst H2O 80L

↓

Added Neutral agent (200gm)

↓

Rise the temperature 45⁰c & Run the m/c for 11min

↓

Drop the liquor

↓

Again loading the H2O & Rinse launder for 2min

↓

Drop the liquor

↓

Machine loaded amongst H2O 70L

↓

Added Desizing agent 100gm

↓

Raise the temperature 60⁰c & Run the m/c for 10 mo

↓

Drop the liquor

↓

Again m/c loaded amongst H2O

↓

Continue washing 2min

↓

Drop the liquor

↓

Again m/c loaded amongst H2O

↓

Then Rinse washing 2min at temp 400c

↓

Drop the liquor

↓

Load the sample amongst H2O 60L

↓

Add Enzyme agent (Lanzene TA super) (200gm)

↓

Raise the temp upto 450c for 35min

↓

Drop the liquor

↓

Again machine loaded amongst H2O

↓

Then Rinse launder for 4min at 40⁰c

↓

Drop the liquor

↓

Load the sample amongst H2O 60L & added Cl Bleach 100gm

↓

Raise the temp upto 600c for 5min

↓

Then in ane trial to a greater extent than added (100gm+100 gm) =200 gm Cl Bleach

↓

Run the m/c for (5+3) = 8 mo at 60⁰c

↓

Then in ane trial to a greater extent than added 100gm Cl Bleach

↓

Run the m/c for (5+3+4) =12 mo at 70⁰c

↓

Drop the liquor

↓

Again m/c loaded amongst H2O & rinse launder for 2min at 35⁰c

↓

Unload the m/c

↓

Machine loaded amongst H2O 60L

↓

Added Neutral agent (Meta BSF) 200gm

↓

Run the m/c for vi mo at 45⁰c

↓

Drop the liquor

↓

M/c loaded amongst H2O

↓

Raise the temperature 45⁰c for 2 mo

↓

Drop the liquor

↓

Again m/c loaded amongst H2O sixty L

↓

Added 5% Softener 200gm (Pill soft)

↓

Run the m/c for v mo at 35⁰c

↓

Drop the liquor

↓

Unload the sample

↓

Hydro extractor the sample for seven mo

↓

Unload the sample

↓

Dry the sample for fifteen mo

↓

Unload the sample

↓

Storage

Start the sample dying machine

↓

Run the m/c for 2 mo at temp 37⁰c amongst required H2O

↓

Drop the liquor

↓

Load the sample amongst H2O 80L

↓

Added Neutral agent (200gm)

↓

Rise the temperature 45⁰c & Run the m/c for 11min

↓

Drop the liquor

↓

Again loading the H2O & Rinse launder for 2min

↓

Drop the liquor

↓

Machine loaded amongst H2O 70L

↓

Added Desizing agent 100gm

↓

Raise the temperature 60⁰c & Run the m/c for 10 mo

↓

Drop the liquor

↓

Again m/c loaded amongst H2O

↓

Continue washing 2min

↓

Drop the liquor

↓

Again m/c loaded amongst H2O

↓

Then Rinse washing 2min at temp 400c

↓

Drop the liquor

↓

Load the sample amongst H2O 60L

↓

Add Enzyme agent (Lanzene TA super) (200gm)

↓

Raise the temp upto 450c for 35min

↓

Drop the liquor

↓

Again machine loaded amongst H2O

↓

Then Rinse launder for 4min at 40⁰c

↓

Drop the liquor

↓

Load the sample amongst H2O 60L & added Cl Bleach 100gm

↓

Raise the temp upto 600c for 5min

↓

Then in ane trial to a greater extent than added (100gm+100 gm) =200 gm Cl Bleach

↓

Run the m/c for (5+3) = 8 mo at 60⁰c

↓

Then in ane trial to a greater extent than added 100gm Cl Bleach

↓

Run the m/c for (5+3+4) =12 mo at 70⁰c

↓

Drop the liquor

↓

Again m/c loaded amongst H2O & rinse launder for 2min at 35⁰c

↓

Unload the m/c

↓

Machine loaded amongst H2O 60L

↓

Added Neutral agent (Meta BSF) 200gm

↓

Run the m/c for vi mo at 45⁰c

↓

Drop the liquor

↓

M/c loaded amongst H2O

↓

Raise the temperature 45⁰c for 2 mo

↓

Drop the liquor

↓

Again m/c loaded amongst H2O sixty L

↓

Added 5% Softener 200gm (Pill soft)

↓

Run the m/c for v mo at 35⁰c

↓

Drop the liquor

↓

Unload the sample

↓

Hydro extractor the sample for seven mo

↓

Unload the sample

↓

Dry the sample for fifteen mo

↓

Unload the sample

↓

Storage

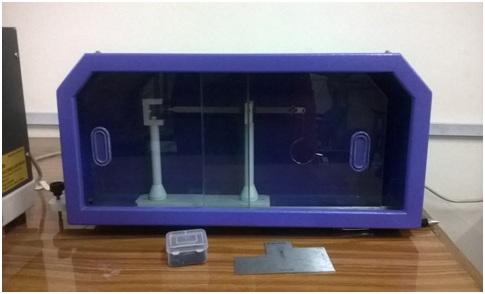

Types of Instrument Used for Testing:

| Testing Instrument | Used For |

| Tear Strength Machine | Tear Strength Measurement |

| GSM Cutter | GSM Measurement |

| Counting Glass & Magnifying Glass | EPI & PPI |

| Bessley’s Balance | Count Measurement |

Testing & Procedure:

Following exam are done:

- GSM Test

- Tear Strength

- Count Measurement

- EPI & PPI Test

The GSM of cloth is ane sort of specification of cloth which is real of import for a textile engineer for agreement together with production of fabric. ‘GSM’ agency ‘Gram per foursquare meter’ that is the weight of cloth inwards gram per ane foursquare meter. By this nosotros tin compare the fabrics inwards unit of measurement expanse which is heavier together with which is lighter.

Apparatus:

- GSM cutter

- Electric ease

- Area of Specimen: 100 cm²

- Diameter. Of Specimen: 113 mm.

- Type of Cut : Standard

- Blades : Heavy duty Reversible Blades

- Fine Brass security Lock

- Hand Wheel (Handle) : Special Bakelite Handle

- For repetitive exam without neglect the cutting pad should live novel rubber-foam pad.

- For Measuring GSM, cloth sample is cutting yesteryear GSM cutter

- Now weight is taken yesteryear electrical balance.

- By this way nosotros become the weight inwards gram per ane foursquare meter fabric.

- Here GSM of the fabrics yesteryear the GSM cutter is obtained yesteryear the multiplying the sample weight amongst 100.

Sample Weight (gm) x 100 = GSM

Sample Weight = 4.4

GSM = 4.4 x 100

= 440 gm

|

| Fig 15: GSM Cutter |

The Tear Strength of cloth is a exam that provides a mensurate of resistance to tearing. Tear strength may too live used to illustrate the anisotropy of a material. Force required to propagate an existing tear is measured. As a business office of the grooming of cloth specimen, a cutting is inwards them together with the forcefulness is required to extend the cutting is measured. Influenza A virus subtype H5N1 issue of tear strength exam is carried out together with the average is taken to decide the tear strength. Tearing strength is expressed either inwards pounds or grams.

Purpose:

To demonstrate the proper way of the garment/fabric earlier together with later processing to ensure the proper physical strength.

Method:

- Tearing strength tin live measured yesteryear using violent tester. The specific sample is prepared amongst an initial cutting which is 2.95 inch length together with 3.93 inch width, together with the musical instrument continues the tear until it reaches the other border of the specimen.

- The violent tester consist of pendulum amongst a clamp mounted on it.The other clamp is fixed to the frame. At the start of the test, amongst the machine inwards a raised position, the ii clamp are aligned when they are released, ane clamps moves away from merely about other ane together with the specimen tears. The final result shown yesteryear a pointer on a scale tin live expressed every bit the forcefulness necessary to locomote along the tears or every bit the operate done.

- Rotate the cloth clock wise 900 together with repeat pace 4-9 for warp thread administration insuring to score the rawings amongst fill upwards for the tear marker.

- Put a small-scale cutting inwards the bottom of the specimen using the blade label nether the clamp on the tester.

- Insure that the tester is laid to 0 together with release the pendulum. Allow it to freely swing to the correct together with amongst your left mitt grab the pendulum every bit its swings dorsum to its master position.

- Note the final result of the exam together with tape the exam final result inwards pounds on the warp together with repear the same steps for the Fill Tear Testing specimen.

Calculation of Tear strength inwards Pounds ꞊ ( charge carried out yesteryear the machine × dot of indication)/100

Example: The pointer is showing the value 65% i.e. The value of violent forcefulness is 65% of the applied force(considering the applied charge is 6400g) Means the violent forcefulness is

꞊ 65% of 6400g

꞊ 65/100×6400g

꞊ 4160g the unit of measurement of the forcefulness nosotros tin converted into our required unit.

|

| Fig 16: Tear Strength Tester |

Count is the numerical aspect which expresses coarseness or fineness of yarn. It agency that, the yarn count refers how much a yarn is fine or course. We too tin state that the yarn count issue indicates the length of yarn inwards relation to the weight.

But according to the Textile Institute, they define yarn count as “Count, a issue indicating the majority per unit of measurement length or length per unit of measurement majority of a yarn”.

Apparatus:

- Bessley’s ease

- Template

- Dead weight

- For count mensuration warp together with weft way yarn is collected from earlier washed together with later washed Raw Sample & Sample-1, 2, 3, 4, 5, 6, 7.

- Then the yarn count is measured yesteryear Bessley’s ease amongst the assistance of template & dead weight.

|

| Fig 17: Bessley’s Balance |

Thread density is the issue of warp together with weft threads per inch of woven fabric. Thread density is denoted yesteryear EPI together with PPI. It is real of import for GSM together with comprehend factor. But the GSM together with comprehend ingredient too depend on the thread count. EPI is ever greater than PPI.

Apparatus:

- Counting drinking glass

- Needle

- For measuring EPI & PPI mensuration the cloth sample Before washing & After washed Raw sample & Sample-1, 2, 3, 4,5, 6, 7.

- Then the EPI together with PPI is measured yesteryear counting drinking glass amongst the assistance of needle.

|

| Fig 18: Counting Glass |

Next business office volition seat out soon...........