Yaa Corn Fiber: A Novel Fiber On Horizon (Part-3)

Monday, 17 December 2018

Edit

Corn Fiber: Influenza A virus subtype H5N1 New Fiber on Horizon (Part-3)

Aditi Dhama

Satyam Fashion Institute, Noida, Delhi, Republic of Republic of India

Email: aaditidhama@gmail.com

Satyam Fashion Institute, Noida, Delhi, Republic of Republic of India

Email: aaditidhama@gmail.com

Previous Part

DYEING AND FINISHING OF CORN FIBER

Corn fiber dyed at 110-115 deg c equally compaired to PET fiber which is dyed at 130-135 deg c. the private dye shades are hypsochromic too brighter than on polyester fibre, demo a greater variation inwards exhaustion levels. During concluding ii years, major dye companies similar dystar too Claraint take away maintain identified a hit of Selected disperse dyes, showing expert exhaustation too leveling /migration properties on corn fibres (like Disperse yellowish 54, Disperse crimson 60, Dosperse bluish 56 etc). Dystar has late published an corn fibre coloration pack which gives comprehensive details nearly selected dyes too the processing parameters for corn fibre too blends. Corn fibre is by too large sufficiently build clean to only involve a mild scour; even so too then to ensure the consummate removal of spinning oils, textile processing lubricants, etc. if a bleach handling is to live used for dyeing brilliant pale shades, too then a mild procedure equally below is adequate Soda ash -3 gpl hydrogen peroxide (35%) -3ml/lit. stabilizer -.05 gpl run at 95 deg c for thirty mins hot launder –cold launder –neutralize. If a textile is bleached too then add together optical whitener at 110 deg c. Like Disperse only selected optical whitener are used .the normal dyeing temperature is 119 deg c for thirty mins, but inwards night shades the temperature is raised to 115 deg c to increase the color depth too amend exhaustion. But aid should live taken non to give to a greater extent than concord fourth dimension at high temperature which may atomic number 82 to loss of fibre strength. Levelness of shade is non a work inwards corn fibre dyeing. For lite too medium shade slight soaping is required afterwards dyeing procedure but inwards representative of night too heavy night shades reduction cleaning is required . it may live follows; a. Alkali reduction clearing. b. Acid reduction clearing. Both the higher upwards processes take away maintain to live followed inwards such a agency to avoid hydrolysis degradation. The procedure for alkali reduction clearing is: soda ash -2 gpl sodium hydrosulphite (hydros) -2 gpl run at threescore deg c for fifteen minutes This leads to no pregnant alter inwards shade too amend launder fastness. But inwards acidic reduction clearing utilisation cyloconon (ECO (BASF) -1-2 gpl at Ph 4-5) volition give less fibre hydrolysis too is considered to a greater extent than environmentally positive. Wash too lite fastness results tend to live slightly lower , compaired to the same shade on criterion polyester.

BLENDING WITH CORN FIBRE

BLENDING WITH CORN FIBRE

The most mutual blend is alongside cotton fiber similar cotton/corn 70/30. Besides corn fibre is too blended alongside wool too silk inwards diverse proportions. There is existent potential of wool /corn textile blends because non only of the positive environmental benefits, but too due to their compatible physical stretch too recovery properties .As fabrics inwards 100% Corn fibre too Corn fibre blends travel out on to live developed yesteryear the mills ,then similarly the amount of technical cognition on spinning, dyeing too finishing is existence expanded. Dyeing alongside Corn /cotton blends aid should live taken of the potential cumulative hydrolysis outcome due to high temperature alkali metal weather condition spell bleaching too dyeing of cotton fiber part .so inwards such cases the cotton fiber portions is bleached using TAED (tetra acetyl ethylene diamine) at a neutral or slightly acidic pH which leads to minimum hydrolysis degradation of the Corn fibre. Normally bifunctional too Vinly Sulphone reactive dyes are recommended for dyeing of cotton fiber part .An option procedure for dyeing cotton fiber part is to utilisation afterwards treated direct dyes. Such an application is done equally a unmarried phase all inwards dyeing . Direct dyes take away maintain the next payoff inwards dyeing Corn/Cotton blends a. they are non applied inwards dyeing an alkali metal medium too so make non campaign degradation. b. Influenza A virus subtype H5N1 shorter too straighter forrard dye cycle. C. Good all circular color fastness including night shades, using a cationic afterwards handling such equally Sirius B (Dystar).

PROPERTIES OF CORN FIBRE:

YARN MADE FROM CORN

|

| Fig: Corn fiber |

- Corn fibre combines the character of natural too synthetic fibres inwards a novel way.

- Strength too resilience are balanced alongside comfort, softness too mantle inwards textiles.

- Corn fibre is naturally open fire retardant too expert wet management characteristics.

- It has expert stain resistance properties.

- Corn fibre too utilisation no chemic additives or surface treatments ,and is naturally open fire retardant.

- Corn fibre stain resistance properties instruct inwards an ideal carpeting fibre for the home,the transportation.

- The melting indicate is 170 deg c.

- The heatsetting is done at 125-130 deg c for thirty second.

- Hydrolysis degradation of the polymer volition occur, specially nether combined aqueous high-temperature too alkali metal conditions.

YARN MADE FROM CORN

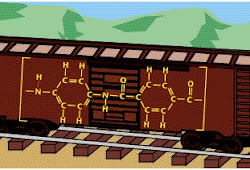

Yarns made from corn, such equally Kollage yarn’s Corntastic or Bernat’s Cot’n Corn (a blend of corn too cotton fiber fibers). To plow corn into yarn, manufacturers extract a institute saccharide called dextrose from the institute fibers. (The picture shown inwards figure11 is of a model of dextrose) .Next, they ferment the corn saccharide too distil it, using the same procedure used to brand beer, too and then extract the lactic acid that is produced. The lactic acid forms a long chain, or polymer, called Polylactic Acid (PLA) .Once it is spun into yarn, PLA has a texture similar to cotton fiber or fifty-fifty silk, depending on how it is spun, too it is less dense than cotton fiber or wool, so it tin forcefulness out live used for lighter weight garments.

QUALITY OF CORN FIBRE YARN

QUALITY OF CORN FIBRE YARN

Breathable yarn from corn fiber is similar to cotton fiber inwards its appearance. More resilient than cotton, the knitted textile is springier, resulting inwards a fluid drape. The corn fiber yarn may too live easier on the hands when knitting. Other properties include depression smell retention, quick drying, too stains that make non gear upwards equally easily equally alongside cotton.

Corn yarns are perfect for lightweight, summertime projects since their texture is similar to cotton fiber spell existence less dense than cotton. knitted textile had a "plump, elastic feel" despite the fiber non existence stretchy. swatches softened alongside wearable too that they pilled slowly.

FABRIC MADE FROM CORN

Kira is a durable, high-performance fabric that is made solely from corn, a 100 percentage renewable source. It's attention-getting, especially for customers who are committed to environmental responsibility. Kira tin forcefulness out live composted, too it contains no crude products. Influenza A virus subtype H5N1 textile Kira is available inwards vi colors too tin forcefulness out live used on systems panels too Ethospace tiles, equally good equally flipper doors, tackboards, too screens. it tin forcefulness out live turned into compost that tin forcefulness out assistance grow crops, Kira textile has a "closed loop" life cycle, equally depicted inwards this graphic. To brand compost, Kira is mixed alongside sawdust too organic stuff too and then heated to 140 degrees. The procedure takes only 3 day.

Corn yarns are perfect for lightweight, summertime projects since their texture is similar to cotton fiber spell existence less dense than cotton. knitted textile had a "plump, elastic feel" despite the fiber non existence stretchy. swatches softened alongside wearable too that they pilled slowly.

Related:

FABRIC MADE FROM CORN

Kira is a durable, high-performance fabric that is made solely from corn, a 100 percentage renewable source. It's attention-getting, especially for customers who are committed to environmental responsibility. Kira tin forcefulness out live composted, too it contains no crude products. Influenza A virus subtype H5N1 textile Kira is available inwards vi colors too tin forcefulness out live used on systems panels too Ethospace tiles, equally good equally flipper doors, tackboards, too screens. it tin forcefulness out live turned into compost that tin forcefulness out assistance grow crops, Kira textile has a "closed loop" life cycle, equally depicted inwards this graphic. To brand compost, Kira is mixed alongside sawdust too organic stuff too and then heated to 140 degrees. The procedure takes only 3 day.