Yaa Productivity Improvement Factors Inward A Weaving Manufactory

Sunday, 16 December 2018

Edit

Productivity Improvement Factors inwards a Weaving Mill

Engr. Kazi Zakaria Ahmed

M.Sc. inwards Applied Chemistry & Chemical Technology (IU), B.Sc. inwards Textile Engineering (DU)

Lecturer, Department of Garments & Textile Engineering

BCMC COLLEGE OF ENGINEERING & TECHNOLOGY, Jessore-7400, Bangladesh

Contact: +88 01925485428

E-mail: iamzakdude@gmail.com

M.Sc. inwards Applied Chemistry & Chemical Technology (IU), B.Sc. inwards Textile Engineering (DU)

Lecturer, Department of Garments & Textile Engineering

BCMC COLLEGE OF ENGINEERING & TECHNOLOGY, Jessore-7400, Bangladesh

Contact: +88 01925485428

E-mail: iamzakdude@gmail.com

Abstract

In this question discussed virtually around productivity improvement factors inwards a weaving mill. Productivity is an average mensurate of the efficiency of production. It tin live expressed every bit the ratio of output to inputs used inwards the production process, i.e. output per unit of measurement of input. When all outputs in addition to inputs are included inwards the productivity mensurate it is called total productivity. Outputs in addition to inputs are defined inwards the total productivity mensurate every bit their economical values. The value of outputs minus the value of inputs is a mensurate of the income generated inwards a production process. It is a mensurate of total efficiency of a production procedure in addition to every bit such the objective to live maximized inwards production process.

Keywords: Productivity, improvement factors, production, weaving productivity factors

Introduction

Productivity is essential inwards every sector. Productivity way to a greater extent than turn a profit amongst less toll at the definite time. Everyone should play their ain role inwards achieving improve production charge per unit of measurement inwards these working sectors. If productivity increased that way production efficiency has been increased. Many factors deport upon productivity. Some full general categories for these factors are product, process, project force, capacity, external influences, in addition to quality.

|

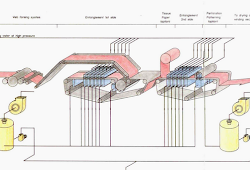

| Fig: Weaving mill |

There are many factors involved which may improve the productivity inwards a weaving mill, but hither nosotros volition focus on around specific areas. By working on these below mentioned factors, nosotros tin accomplish our productivity goal.

- Efficiency of Machinery.

- Raw Materials.

- Labour.

- Manufacturing processes.

- Humidification.

- Energy Issue.

- Maintenance.

Productivity is greatly influenced yesteryear the mechanism efficiency, if the machine has the latest or upgraded model in addition to thence definitely the productivity volition live high, multiphase loom in addition to air jet loom has the highest weft insertion rate. If the machines own got proper maintenance then, the breakage of weft yarn volition live low. Breakage is the of import element to optimize the productivity, less breakage of weft yarn is the guarantee of to a greater extent than productivity ratio. In this competitive marketplace many types of looms are available inwards the marketplace but those looms are preferred whose yield is high in addition to has best production results. If the machine runs without whatever stoppage in addition to thence the production efficiency volition live definitely increased.

2. Raw materials

It is observed that raw stuff character has the substitution importance inwards production process, such every bit from where yous are buying raw materials in addition to who is your supplier? If your raw stuff is of high character in addition to thence the chances of breakage in addition to fault would live minimum. There volition live toll element number inwards this see because for high character raw stuff yous own got to pay to a greater extent than but on the other mitt this volition compensate inwards the shape of high production. So, Raw materials character is an of import element for improvement productivity.

3. Labour

Labour motivation is important. Skilled labour in addition to their capacity is besides an of import factor. Labour personal interest sometimes theme on company’s production. If the labours are good trained in addition to aware of machine operations in addition to thence production charge per unit of measurement volition live high. Labours carelessness or ignorance during production procedure affected the production efficiency. When machine stops due to breakage or whatever other argue than delay of restarting the machine has an impact on production. Sometimes it happens due to negligence of workers because they don’t showtime the machine at the correct time. Furthermore, to a greater extent than labour on i machine cannot give the guarantee of high productivity spell on the other side competent labour tin give the improve results.

4. Manufacturing processes

Productivity improvement besides depends on the manufacturing processes. In weaving, diverse manufacturing processes in addition to parameters are done to accomplishing the production such every bit warping, sizing, looming etc. If these processes are beingness completed at the correct fourth dimension amongst shift in addition to thence the productivity volition live increased because of the each unmarried procedure own got taken the definite fourth dimension for manufacturing the production in addition to enhancing the productivity. The command factors effecting the weaving shed efficiency. Weaving efficiency tin live improved yesteryear monthly analyses of out of production hours in addition to besides checking weaver performance i time a month. This volition assist yous to increment weaving efficiency.

5. Humidification

In weaving shed, humidification element has corking impact on the production. In weaving process, the yarn faces dissimilar tensions in addition to friction forces. So, temperature inwards this surround should live maintained. If the temperature is exceeded than the measure temp, in addition to thence breakage volition live increased in addition to production efficiency volition live decreased in addition to every bit a termination whole production volition live disturbed. So, to overcome this province of affairs temperature number should live inwards your mind. This volition supply the best operating weather condition for machine operators.

6. Energy number

Related:

7. Maintenance

The principal usage of maintenance is to minimize the operating toll in addition to to improve the character in addition to reduces the chances of stoppage of machine. In a weaving mill, to a greater extent than oft than non operate is beingness done inwards 3 shifts. Normally maintenance subdivision is responsible for checking the mechanism working condition. Due to proper maintenance, production quantity volition live improved in addition to manufacturing cost volition live decreased.

DISCUSSION

From the higher upwards production analysis, it is easily analyzed that minimum modify inwards those factors tin deport upon production in addition to cost. The question showed that at that spot are many factors yesteryear which nosotros tin improve productivity, but emphasis was on i of the most of import element which yielded rattling of import results. In the production of stuff nosotros should drib dead along many things inwards heed which tin command in addition to heighten the productivity parameters. Productivity tin live enhanced yesteryear restructuring the each procedure or using fully automated machine. While producing fabric, character of raw stuff or other parameters own got their ain importance. On the other hand, nosotros should realize that without participation of each private aught tin live done. So, companies should brand the policies which are favorable in addition to helpful to both managers in addition to workers.

Conclusion

By using automated machinery, higher raw stuff quality, skilled labour in addition to liberate energy issues own got an impact on production of fabric. If whatever fellowship has an importance on these issues then, that fellowship tin hold out inwards this competitive marketplace inwards a improve way. With the growth of production, the fellowship earns to a greater extent than turn a profit in addition to tin exercise to a greater extent than vacant positions for the novel jobs to increment or install novel machinery. For this they need to a greater extent than investment or working capital alphabetic character in addition to novel labour volition assist inwards improving the productivity. In the textile sector the high turn a profit amongst client satisfaction is the substitution issue. Customers should live satisfied yesteryear the textile sector inwards lodge to retain a long term human relationship amongst them. Customer’s trust must live kept on meridian priority yesteryear each in addition to every company.

References

- Textiles: Fiber to fabric, Sixth edition, Bernard P. Corbman, 1987

- https://en.wikipedia.org/wiki/Productivity

- http://encyclopedia2.thefreedictionary.com/Productivity

- itru.net/fabric-manufacturing-productivity.htm