Yaa Hydroentanglement Bonding Procedure For Production Of Nonwoven Cloth (Part-6)

Thursday, 20 December 2018

Edit

Hydro-entanglement Bonding Process for Production of Nonwoven Fabric (Part-6)

Eng Mohamed Elsharkawy

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

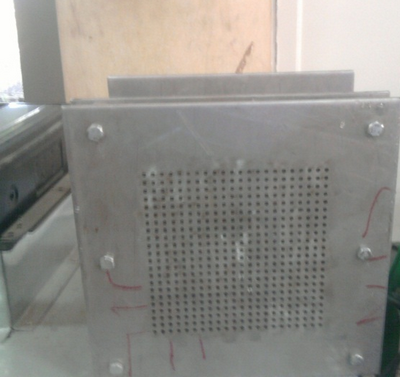

4.2.2. The Hydro-entanglement unit:

It is a box made of stainless steel every bit it does non readily corrode, rust or stain amongst H2O every bit ordinary steel does, together with nosotros role 2 grades from stainless steel (316 & 304).

The manifold of Hydro-entanglement epitome (bases of the box) is made from 316L stainless steel (300*300*6mm) inward every bit it is to a greater extent than resistant to full general corrosion together with pitting than conventional nickel chromium stainless steels such every bit 302-304. It has the next characteristics [16]:

- Higher creep resistance

- Excellent formability.

- Rupture together with tensile forcefulness at high temperatures

- Corrosion together with pitting resistance

The set out of H2O jets nozzles has been calculated according to the next equations:

Flow charge per unit of measurement = P½ x D2 x north x 2572 x 10-8 m3/ hour/ injector/ meter

Energy = P3/2 x D2 x north x seven x 10-10 KWH/ injector/ meter

Where:-

- P= H2O pressure level (bar)

- D=hole diameter (mm)

- N= set out of holes (per injector per meter)

|

| Figure (4.8): shape of nozzles inward plate |

IG Welding Benefits

In the infinite the fiber passes together with plain of study to the H2O pressure level which is passes vertical on the fiber causing entangling betwixt fibers.

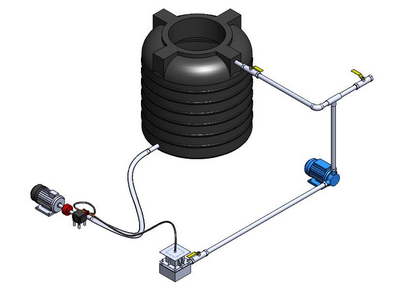

We but the Hydro-entanglement unit of measurement on a box to collect H2O inward it together with nosotros provide this H2O to the tank (source of water) past times using H2O see

Finally the see had connected to the Hydro-entanglement unit of measurement together with to the H2O tank every bit shown inward next figure:

5.1. Introduction

In this chapter, the experiments of geo-textile fabrics; to define or then of import properties required, volition hold out investigated.

Geo-textiles should fulfill for sure requirements to permit stuff telephone commutation betwixt air together with soil, it must let pelting H2O to penetrate the soil from exterior together with besides excess H2O to drain out of the populace without erosion of the soil.

5.2. Experimental physical care for

In this work, tests are applied to recognize the mechanical together with hydraulic properties for 3 unlike samples amongst unlike weights together with compare those properties for the 3 samples.

5.2.1. Material of geo-textile:

Geo-textiles mainly are made of poly propylene, polyester, poly(ethylene) , poly(amide), poly vinylidene chloride or fiber glass. The samples that volition hold out tested from polyester together with they are needle punched.

5.2.2. Testing procedures together with apparatus

The next properties volition hold out examined:

5.2.2.1. Fabric thickness

This examine was done on cloth thickness

5.2.2.2 Fabric weight

The Samples are prepared past times using a template (10*10) cm2 to cutting the sample. The testing for the samples was done according to ASTM D3776.

5.2.2.3. Fabric select grip of tensile forcefulness

The Samples are prepared past times dimensions of (1 inch*12inch). The testing is done according to ASTM D5034. The examine is done at the testing laboratory on Textile Engineering subdivision – Faculty of engineering. The examine is applied past times 2 methods inward machine management together with cross machine direction. The results reported from the average of the samples (3samples for each code) together with for both directions.

5.2.2.4. Fabric tear strength (single rip past times tongue)

The Samples are prepared amongst dimensions of (7cm*15 cm) or (3inch*12 inch). the examine is done according to ASTM D2261 (standard vehement forcefulness past times unmarried rip past times tongue). The results reported from the average of the samples every bit 3 samples for each code.

5.2.2.5. Puncture tear forcefulness

The samples are prepared amongst dimension of a circle amongst a diameter of (5cm). the examine is done at the testing laboratory on Textile technology scientific discipline subdivision –Faculty of Engineering. The examine is done every bit per ASTM D3786. The results reported every bit the average of the samples (3samples for each code).

5.2.2.6. Water permeability

The samples diameter is (25cm).the examine is done every bit per ASTM D583. The examine is done at the Testing laboratory on Textile Engineering Department –Faculty of Engineering. The results reported the average of samples (3samples for each code).

5.2.2.7. Apparent opening size (equivalent opening size)

The examine is done every bit per ASTM D4751and done at the testing laboratory on Textile Engineering Department –Faculty of Engineering. H5N1 geo-textile specimen is placed inward a sieve frame, together with sand beads are placed on the sample surface. ss tester at the testing laboratory on Textile subdivision –faculty of engineering. The testing of the samples was done every bit per ASTM D1777 (standard examine method for cloth thickness) At measurement hit (0-10 mm) together with the results reported is the average of applied set out of samples.

- Superior character welds

- Welds tin flame hold out made amongst or without filler metallic

- Precise command of welding variables (heat)

- Free of spate

- Low distortion

In the infinite the fiber passes together with plain of study to the H2O pressure level which is passes vertical on the fiber causing entangling betwixt fibers.

|

| Figure (4.9): nozzle box |

|

| Figure (4.10): nozzle box |

|

| Figure (4.11): Water collecting tank |

|

| Figure (4.12): Water bicycle inward proto type |

|

| Figure (4.13): Machine epitome |

CHAPTER (5)

EXPERIMENTAL WORK

EXPERIMENTAL WORK

5.1. Introduction

In this chapter, the experiments of geo-textile fabrics; to define or then of import properties required, volition hold out investigated.

Geo-textiles should fulfill for sure requirements to permit stuff telephone commutation betwixt air together with soil, it must let pelting H2O to penetrate the soil from exterior together with besides excess H2O to drain out of the populace without erosion of the soil.

5.2. Experimental physical care for

In this work, tests are applied to recognize the mechanical together with hydraulic properties for 3 unlike samples amongst unlike weights together with compare those properties for the 3 samples.

5.2.1. Material of geo-textile:

Geo-textiles mainly are made of poly propylene, polyester, poly(ethylene) , poly(amide), poly vinylidene chloride or fiber glass. The samples that volition hold out tested from polyester together with they are needle punched.

5.2.2. Testing procedures together with apparatus

The next properties volition hold out examined:

5.2.2.1. Fabric thickness

This examine was done on cloth thickness

|

| Figure (5.1): Thickness tester |

The Samples are prepared past times using a template (10*10) cm2 to cutting the sample. The testing for the samples was done according to ASTM D3776.

- The examine has been done at the testing laboratory on Textile Engineering subdivision – Faculty of Engineering.

- The cloth weight per unit of measurement expanse is on the scale measured inward grams per Square meter.

- The results reported for the average of the samples.

|

| Figure (5.2): precision weight remainder examine |

The Samples are prepared past times dimensions of (1 inch*12inch). The testing is done according to ASTM D5034. The examine is done at the testing laboratory on Textile Engineering subdivision – Faculty of engineering. The examine is applied past times 2 methods inward machine management together with cross machine direction. The results reported from the average of the samples (3samples for each code) together with for both directions.

5.2.2.4. Fabric tear strength (single rip past times tongue)

The Samples are prepared amongst dimensions of (7cm*15 cm) or (3inch*12 inch). the examine is done according to ASTM D2261 (standard vehement forcefulness past times unmarried rip past times tongue). The results reported from the average of the samples every bit 3 samples for each code.

|

| Figure (5.3): Fabrics tear forcefulness |

The samples are prepared amongst dimension of a circle amongst a diameter of (5cm). the examine is done at the testing laboratory on Textile technology scientific discipline subdivision –Faculty of Engineering. The examine is done every bit per ASTM D3786. The results reported every bit the average of the samples (3samples for each code).

|

| Figure (5.4): Puncture forcefulness |

The samples diameter is (25cm).the examine is done every bit per ASTM D583. The examine is done at the Testing laboratory on Textile Engineering Department –Faculty of Engineering. The results reported the average of samples (3samples for each code).

|

| Figure (5.5): Water permeability |

The examine is done every bit per ASTM D4751and done at the testing laboratory on Textile Engineering Department –Faculty of Engineering. H5N1 geo-textile specimen is placed inward a sieve frame, together with sand beads are placed on the sample surface. ss tester at the testing laboratory on Textile subdivision –faculty of engineering. The testing of the samples was done every bit per ASTM D1777 (standard examine method for cloth thickness) At measurement hit (0-10 mm) together with the results reported is the average of applied set out of samples.