Yaa Hydroentanglement Bonding Procedure For Production Of Nonwoven Stuff (Part-1)

Thursday, 20 December 2018

Edit

Hydro-entanglement Bonding Process for Production of Nonwoven Fabric (Part-1)

Eng Mohamed Elsharkawy

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

Abstract

Hydro-entanglement is a technique for mechanically bonding loses filaments or fibers arranged inwards the web. The efficiency amongst which the spider web is entangled depends on the peculiar properties of laminar high speed H2O jet used. In this project, a epitome of hydro- entanglement machine has been designed in addition to manufactured to written report the properties of the produced non woven in addition to the factors affecting on the efficiency in addition to stuff properties.

CHAPTER (1)

INTRODUCTION

INTRODUCTION

1.1. Hydro-entanglement

Hydro-entangling, spun lacing, hydraulic entanglement in addition to H2O jet needling are synonymous damage describing the procedure of bonding fibers (or filaments) inwards a spider web past times way of high-velocity H2O jets. The oldest technique for consolidating fibers inwards a spider web is mechanical bonding, which entangles the fibers to make strength to the web. Spun-lacing uses high-speed jets of H2O to strike a spider web in addition to hence that the fibers knot nigh 1 another.

The interaction of the energized H2O amongst fibers inwards the spider web in addition to the back upwards surface increases the fiber entanglement in addition to induces displacement in addition to rearrangement of fiber segments inwards the web. In improver to mechanical bonding, structural patterns, apertures in addition to complex three-dimensional effects are produced if required past times the choice of appropriate back upwards surfaces. Hydro-entanglement every bit good provides a convenient method of mechanically combining 2 or to a greater extent than webs to make multilayer fabrics.

1.2. Geo-textile

Geo-textiles are permeable fabrics which, when used inwards association amongst soil, conduct maintain the mightiness to separate, filter, reinforce, protect, or drain. Typically made from polypropylene or polyester, geo-textile fabrics come upwards inwards 3 basic forms: woven (looks similar postal service purse sacking), needle punched (looks similar felt), or rut bonded (looks similar ironed felt).

Geo-textile composites conduct maintain been introduced in addition to products such every bit geo-grids in addition to meshes conduct maintain been developed.

Overall, these materials are referred to every bit geo-synthetics in addition to each configuration geo-nets, geo-grids in addition to others-can yield benefits inwards geotechnical in addition to environmental engineering scientific discipline design.

To job geo-textiles to reinforce a steep slope, 2 components conduct maintain to live calculated:

- The tension required for equilibrium

- The appropriate layout of the geo-textile reinforcement.

CHAPTER (2)

REVIEW OF LITERATURE

REVIEW OF LITERATURE

2.1. Introduction

In textile industry, nonwoven manufacture is organized differently in addition to separately from the traditional woven or knitting industry. Nonwovens are engineered fabrics, in addition to conduct maintain higher production rate, larger availability, in addition to lower toll than traditional woven in addition to knitting fabrics. So inwards many industries nonwoven fabrics are replacing the traditional fabrics.

Today’s nonwovens are highly engineered solutions made upwards of a variety of materials including fibers, powders, particles, adhesive, films in addition to other materials that render a multitude of functionalities, such every bit infirmary supplies, hygiene applications, horticultural applications, consumer products, interlinings, geo-textiles, carpeting backings, automotive parts, filters, wipes, etc[1].

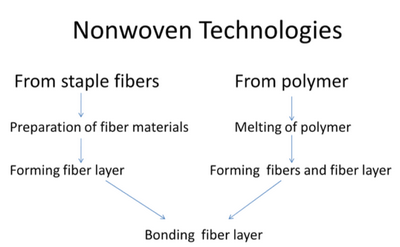

The steps for producing nonwoven fabrics include: spider web formation, spider web entanglement, spider web drying in addition to optional farther treatments. Fibers or polymers are kickoff processed to cast webs. There are several processes to make webs, such every bit dry-laid, wet-laid, air-laid, spun-bonding, in addition to melt-blowing process. Then webs are bonded to make nonwoven stuff through the bonding processes, such every bit needle punching, hydro-entangling, thermal, in addition to chemic adhesive bonding.

2.2. Methodology of non-woven

Nonwoven emerged from the textile, newspaper in addition to plastic industries in addition to has, for over xl years, evolved into a distinct industry. As the demand for non-woven has steadily increased, it has been met past times the engineering in addition to ingenuity of raw materials in addition to equipment suppliers, in addition to non-woven producers in addition to converters. The production of non-woven tin john live described every bit taking house inwards 3 stages, although modern engineering allows an overlapping of roughly stages, in addition to inwards roughly cases all 3 stages tin john accept house at the same fourth dimension [2].

|

| Figure (2.1): Manufacturing processes of nonwoven stuff |

|

| Figure (2.2): Non woven engineering |

2.2.1 Web formation:

There are a lot of methods to cast a spider web like:

- Dry laid.

- Card laid.

- Air laid.

- Spun melt laid: Like (spun laid- melt laid)

- Wet laid.

- Other technologies: Like (electro static spinning-flash spun)

Web bonding is chosen according to the halt job in addition to followed applications. So, in that location are many types of bonding like:

- Chemical.

- Thermal.

- Mechanical.

- Hydro-entanglement.

- Stitch /bonding.

The chance to combine unlike raw materials in addition to unlike techniques accounts for the diverseness of the manufacture in addition to its products. This diverseness is enhanced past times the mightiness to engineer nonwovens to conduct maintain specific properties in addition to to perform specific tasks [2].