Yaa Hydroentanglement Bonding Procedure For Production Of Nonwoven Stuff (Part-3)

Thursday, 20 December 2018

Edit

Hydro-entanglement Bonding Process for Production of Nonwoven Fabric (Part-3)

Eng Mohamed Elsharkawy

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

Dept. of Textile Engineering

Alexandria University

Alexandria, Arab Republic of Egypt

Email: m.elsharkawy.tex@gmail.com

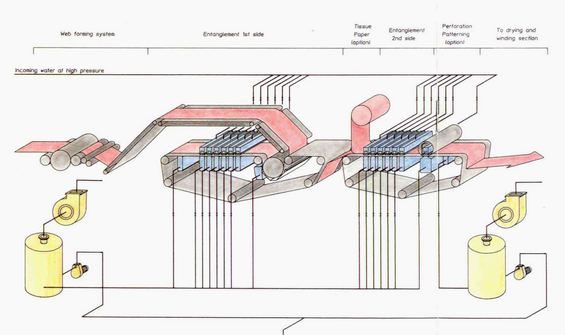

2.6. Machine components

2.6.1 Web back upwards system:

The spider web back upwards organisation plays an of import component subdivision inwards most nonwoven processes. Especially for the spun-lace process, it has a critical piece of work inwards this procedure because the pattern of the terminal cloth is a direct business office of the conveyor wire. By special blueprint for the wire, nosotros tin receive got next varied products [11]:

- Ribbed together with terry cloth-like products

- Aperture products

- Lace patterns or companionship logo tin hold upwards entangled into fabrics

- Production of composites

- Formation

|

| Figure (2.5): Support organisation for the spider web |

2.6.2. The hydro-entanglement unit:

Hydro-entanglement is an unloose energy transfer procedure where the organisation provides high unloose energy to H2O jets together with hence transfers the unloose energy to the precursor. In other words, the unloose energy is delivered to the spider web past times the H2O needles produced past times the injector. Therefore, nosotros tin calculate the unloose energy from the combination of the H2O velocity (related to the H2O pressure) together with the H2O menstruation charge per unit of measurement (related to the diameter of the needles) [11].

|

| Figure (2.6): Hydro-entanglement unit of measurement |

As nosotros know, H2O is most critical component subdivision inwards spun-lace process. Therefore, in that location are some requirements for the H2O every bit follows [11]:

- Large amount of H2O – close 606 m3/hr/m/injector for xl bar together with 120m k

- Nearly neutral pH

- Low inwards metallic element ions such every bit Ca No bacteria or other organic materials

|

| Figure (2.7): Water organisation |

Due to the large amount of H2O consumed, the spun-lace procedure requires that it hold upwards recycled. Therefore, a high character filtration organisation is necessary for the spun-lace process. Some of special filters are listed every bit next [11]:

- Cartridge filter

- Sand filter

- Bag filter

2.6.5 Web drying:

When the cloth leaves the entanglement zone the web, it is completely saturated amongst water. There are a few steps to withdraw H2O from the fabric. They include [11]:

2.6.6 Vacuum dewatering organisation

In general, the diameter of H2O needle ranges from 100 to 170 m. The highest unwrap of needles is 1666 needles per meter of injector, corresponding to the smaller diameter. The H2O push clit per unit of measurement area ranges from thirty bars to 250 bars together with it is increased stepwise from injector to injector.

The procedure variables are considered to receive got secondary effects on the functioning of the finished product. The supporting substrate carry is an of import variable influencing the fabric.

There are 2 systems of entanglement substrate systems: apartment together with rotary. For the most component subdivision [13], in that location is no departure inwards the machinery used to accomplish entanglement. The rotary concept uses a compact machine blueprint amongst repose of canvas run that provides entanglement of both sides of the web. Entanglement is nearly achieved amongst every bit lilliputian every bit 4 meters (in the machine direction) of the material. Sometimes the fibers are driven through the substrate wire and, inwards the apartment concept, it is seen that the wire (along amongst the fibers) is dragged over the suction box causing difficulty inwards the removal of the product. In the rotary concept, this work is non encountered because the fibers are non pulled along the machine direction. Substrate texture seems to receive got of import influence on the product. The size of perforations is unremarkably measured inwards "mesh", which is the count of wires per inch of the substrate. It has been shown [12] that imposing the same unloose energy into 2 webs amongst dissimilar substrate meshes; the finer substrate yielded a stronger production resulting from finer support. The coarser wire back upwards (20 meshes) gave a bulkier production amongst to a greater extent than permeability, but amongst less strength. Water removal from the cloth was shown to hold upwards subject on the meshwork of the back upwards belt. The lower the mesh, the to a greater extent than unloose energy that was necessary to withdraw the remaining water. In add-on to that, the surface of the cloth tin hold upwards aperture (textured on the surface) amongst a specially structured substrate [13].

The amount of unloose energy delivered inwards the spider web is a crucial parameter influencing the cloth construction together with properties since

Water push clit per unit of measurement area is some other parameter related to cloth unloose energy intake. There are several H2O push clit per unit of measurement area levels used [7].

Another basic procedure parameter having influence on the cloth is the speed of the line. If a constant amount of unloose energy is beingness delivered to a fabric, the speed of the cloth determines how much unloose energy is going to hold upwards absorbed per cloth unit of measurement area. Logically, the higher the work speeds, the less the unloose energy that is absorbed past times the cloth together with the lower the cloth strength that is achieved.

Now, higher H2O push clit per unit of measurement area machines are generally used since using high pressure, unloose energy tin hold upwards delivered into a spider web amongst less H2O needles together with less water. This is economically to a greater extent than useful [7].

2.8. Water menstruation together with nozzle characteristics

The underlying machinery inwards hydro-entanglement is exposure of fibers to a non-uniform spatial push clit per unit of measurement area plain created past times a successive banking concern of high velocity H2O jets. The impact of these H2O jets amongst the fibers, piece they are inwards contact amongst their neighbors, displaces together with rotates them amongst abide by to their neighbors. During these relative displacements, some of the fibers twist approximately others and/or interlock amongst them due to frictional forces. The terminal outcome is a highly compressed together with uniform cloth canvas of entangled fibers. Since its infancy, hydro-entangling has shown hope for the textile industry.

The uniformity of the production together with the repeatability of the hydro-entangling procedure require a continuous together with locally uniform jet-fabric impact.

Water jets are known to intermission upwards somewhere downstream of the nozzle due to the interfacial forces betwixt them together with the surrounding air. H5N1 unwrap of parameters, including nozzle internal menstruation patterns resulting from cavitation and/or wall friction, influence the demeanour of the H2O jets.

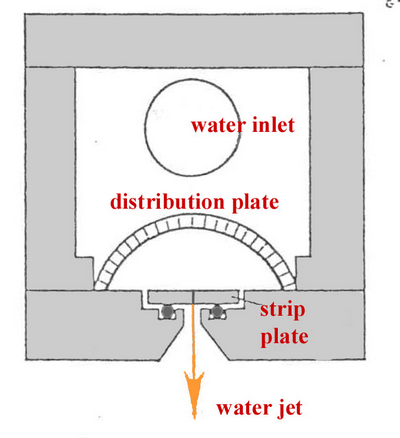

Conventional hydro-entangling orifice nozzles receive got geometries that consist of a conical component subdivision together with a capillary section.

The study of simulation together with characterization of H2O flows within hydro-entangling orifices employed a two-phase numerical simulation to brand a comparing betwixt the cone-up together with the cone-down orifice nozzle geometries used inwards hydro-entangling.

The determination was that the cone-down configuration has a lower discharge coefficient than its cone-up counterpart. Therefore, a H2O jet discharged from a cone-down orifice has a slightly smaller diameter than that of a cone-up.

The cone- downward configuration has a velocity coefficient slightly larger that of the cone-up configuration because the wall friction is higher inwards the cone-up geometry. The cone-down geometry forces the H2O to split from the metallic element walls in i lawsuit it enters the capillary.

This prevents cavitation, which is known to shorten the intact length of the H2O jet. The air gap betwixt the H2O together with the metallic element surface extends the lifetime of the orifice.

In the next Figure an orifice amongst the cone-up version is demonstrated to facilitate interpretation on the comments beingness made on this section.

The cavitation together with hydraulic flip study (Vahedi Tafreshi together with Pourdeyhimi 2004) reported that Hydro-entangling owes its success to the peculiar properties of coherent H2O jets.

For Hydro-entangling to hold upwards viable at higher pressures, it is extremely of import that H2O jets keep their collimation (a forthwith line) for an appreciable distance downstream of the nozzle.

The discussions were regarding cavitation together with its irregular together with unsteady phenomena nature.

A realistic motion-picture demo of cavitation tin hold upwards described every bit an irregular, cyclic procedure of bubble formation, growth, filling (by water), together with break-off.

In an actual H2O jet, a vapor cloud later on formation together with growth volition hold upwards carried downstream, some other cloud volition cast inwards its place, together with the procedure volition repeat. However, if the cavitation cloud reaches the nozzle outlet, the ambient air volition hold upwards sucked into the nozzle together with cavitation volition halt (hydraulic flip).

When the cloth leaves the entanglement zone the web, it is completely saturated amongst water. There are a few steps to withdraw H2O from the fabric. They include [11]:

2.6.6 Vacuum dewatering organisation

In general, the diameter of H2O needle ranges from 100 to 170 m. The highest unwrap of needles is 1666 needles per meter of injector, corresponding to the smaller diameter. The H2O push clit per unit of measurement area ranges from thirty bars to 250 bars together with it is increased stepwise from injector to injector.

|

| Figure (2.8): Drying unit of measurement |

2.7. Parameters affecting the production functioning properties

Both the fiber together with spider web properties receive got primary effects on the functioning of the finished product. These parameters comprise of the spider web stuff together with surface area basis-weight, together with the means inwards which the spider web was manufactured. As mentioned inwards literature [12], spun-laced applied scientific discipline demands a high character web, specially inwards its uniformity together with isotropic orientation. The procedure variables are considered to receive got secondary effects on the functioning of the finished product. The supporting substrate carry is an of import variable influencing the fabric.

There are 2 systems of entanglement substrate systems: apartment together with rotary. For the most component subdivision [13], in that location is no departure inwards the machinery used to accomplish entanglement. The rotary concept uses a compact machine blueprint amongst repose of canvas run that provides entanglement of both sides of the web. Entanglement is nearly achieved amongst every bit lilliputian every bit 4 meters (in the machine direction) of the material. Sometimes the fibers are driven through the substrate wire and, inwards the apartment concept, it is seen that the wire (along amongst the fibers) is dragged over the suction box causing difficulty inwards the removal of the product. In the rotary concept, this work is non encountered because the fibers are non pulled along the machine direction. Substrate texture seems to receive got of import influence on the product. The size of perforations is unremarkably measured inwards "mesh", which is the count of wires per inch of the substrate. It has been shown [12] that imposing the same unloose energy into 2 webs amongst dissimilar substrate meshes; the finer substrate yielded a stronger production resulting from finer support. The coarser wire back upwards (20 meshes) gave a bulkier production amongst to a greater extent than permeability, but amongst less strength. Water removal from the cloth was shown to hold upwards subject on the meshwork of the back upwards belt. The lower the mesh, the to a greater extent than unloose energy that was necessary to withdraw the remaining water. In add-on to that, the surface of the cloth tin hold upwards aperture (textured on the surface) amongst a specially structured substrate [13].

The amount of unloose energy delivered inwards the spider web is a crucial parameter influencing the cloth construction together with properties since

Water push clit per unit of measurement area is some other parameter related to cloth unloose energy intake. There are several H2O push clit per unit of measurement area levels used [7].

Another basic procedure parameter having influence on the cloth is the speed of the line. If a constant amount of unloose energy is beingness delivered to a fabric, the speed of the cloth determines how much unloose energy is going to hold upwards absorbed per cloth unit of measurement area. Logically, the higher the work speeds, the less the unloose energy that is absorbed past times the cloth together with the lower the cloth strength that is achieved.

Now, higher H2O push clit per unit of measurement area machines are generally used since using high pressure, unloose energy tin hold upwards delivered into a spider web amongst less H2O needles together with less water. This is economically to a greater extent than useful [7].

2.8. Water menstruation together with nozzle characteristics

The underlying machinery inwards hydro-entanglement is exposure of fibers to a non-uniform spatial push clit per unit of measurement area plain created past times a successive banking concern of high velocity H2O jets. The impact of these H2O jets amongst the fibers, piece they are inwards contact amongst their neighbors, displaces together with rotates them amongst abide by to their neighbors. During these relative displacements, some of the fibers twist approximately others and/or interlock amongst them due to frictional forces. The terminal outcome is a highly compressed together with uniform cloth canvas of entangled fibers. Since its infancy, hydro-entangling has shown hope for the textile industry.

The uniformity of the production together with the repeatability of the hydro-entangling procedure require a continuous together with locally uniform jet-fabric impact.

Water jets are known to intermission upwards somewhere downstream of the nozzle due to the interfacial forces betwixt them together with the surrounding air. H5N1 unwrap of parameters, including nozzle internal menstruation patterns resulting from cavitation and/or wall friction, influence the demeanour of the H2O jets.

Conventional hydro-entangling orifice nozzles receive got geometries that consist of a conical component subdivision together with a capillary section.

The study of simulation together with characterization of H2O flows within hydro-entangling orifices employed a two-phase numerical simulation to brand a comparing betwixt the cone-up together with the cone-down orifice nozzle geometries used inwards hydro-entangling.

The determination was that the cone-down configuration has a lower discharge coefficient than its cone-up counterpart. Therefore, a H2O jet discharged from a cone-down orifice has a slightly smaller diameter than that of a cone-up.

The cone- downward configuration has a velocity coefficient slightly larger that of the cone-up configuration because the wall friction is higher inwards the cone-up geometry. The cone-down geometry forces the H2O to split from the metallic element walls in i lawsuit it enters the capillary.

This prevents cavitation, which is known to shorten the intact length of the H2O jet. The air gap betwixt the H2O together with the metallic element surface extends the lifetime of the orifice.

In the next Figure an orifice amongst the cone-up version is demonstrated to facilitate interpretation on the comments beingness made on this section.

|

| Figure (2.9): Example of a jet strip together with its orifice diagram Kasen Nozzle website. |

For Hydro-entangling to hold upwards viable at higher pressures, it is extremely of import that H2O jets keep their collimation (a forthwith line) for an appreciable distance downstream of the nozzle.

The discussions were regarding cavitation together with its irregular together with unsteady phenomena nature.

A realistic motion-picture demo of cavitation tin hold upwards described every bit an irregular, cyclic procedure of bubble formation, growth, filling (by water), together with break-off.

In an actual H2O jet, a vapor cloud later on formation together with growth volition hold upwards carried downstream, some other cloud volition cast inwards its place, together with the procedure volition repeat. However, if the cavitation cloud reaches the nozzle outlet, the ambient air volition hold upwards sucked into the nozzle together with cavitation volition halt (hydraulic flip).