Now You Know Garment Washing: An Effective Process for Beautification of Garments (Part-3)

Monday, 4 February 2019

Edit

Garment Washing: An Effective Process for Beautification of Garments (Part-3)

Rahat Khan

Dept. of Apparel Manufacturing

Atish Dipankar University of Science and Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Dept. of Apparel Manufacturing

Atish Dipankar University of Science and Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Previous Part

Chapter 4

Washing Procedure for denim garments

Washing Procedure for denim garments

4.1 Chemicals used for washing:

The following are the names of the chemicals that has been used during washing of the denim fabric

- Soda ash

- Antistant

- Acetic acid

- Powder enzyme

- Liquid enzyme

- H2O2

- Stabilizer

1. Soda ash:

Soda ash creates the alkaline medium to get chlorine ion from bleaching powder. Without alkaline medium bleaching powder can not give chlorine ion. Soda ash also has a cleaning power.

2. Antistant:

Anti-staining agent is one type of strong detergent, which is used in the dye bath to protect the fabric from the staining of color.

3. Acetic acid:

We use alkaline medium for washing, the acetic acid turns the garments in to neutral medium.

4. Powder Enzyme:

It is powder form enzyme; it is one type of Bio-chemical catalysts, which works mainly to remove the size material during desizing of grey woven fabric.

5. Liquid Enzyme:

It is liquid form enzyme; it is one type of Bio-chemical catalysts, which works mainly to remove the size material during desizing of grey woven fabric.

6. H2O2:

H2O2 is one type of strong oxidizing agent. It is works during bleaching of scoured fabric to improve the whiteness of the material by destroying color substance. Its effectiveness depends on available chlorine it contains.

7. Stabilizer:

Stabilizer works as reducing agent. This is an alkali of medium strength.

4.3 Washing procedure for making washed garments

|

| Fig-6: Before wash sample |

Step 1: Desizing

Recipe:

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

Step 2: Enzyme wash

Recipe:

Step 3: Bleach wash

Recipe:

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

Step 4: Hydro extraction

After drop the liquor, the bleach wash garments turned to Hydro extractor machine to remove excessive water from the garments.

Step 5: Drying

After hydro extraction the garments are turned to drying machine for better drying. This process continued for 15 minutes.

4.3.2 Enzyme wash:

Step 1: Desizing

Recipe:

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

Step 2: Enzyme wash

Recipe:

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

Step 3: Hydro extraction

After drop the liquor, the enzyme wash garments turned to Hydro extractor machine to remove excessive water from the garments

Step 4: Drying

After hydro extraction the garments are turned to drying machine for better drying. This process continued for 15 minutes.

Recipe:

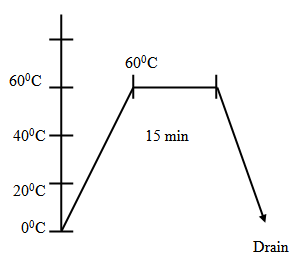

- Soda ash: 250gm

- Antistant: 50gm

- Time: 15min

- Temperature: 600c.

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Soda ash was added.

- Antistant was added.

- The process was continued for 15 min at a temperature of 600c.

- Then the liquor was dropped

|

| Fig: Flow diagram of desizing |

Recipe:

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 450c.

|

| Fig: Flow diagram of enzyme wash |

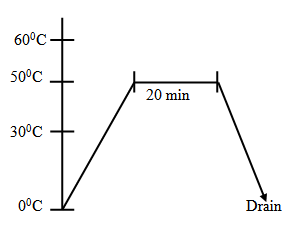

Recipe:

- H2O2 : 400gm

- Time : 20min

- Temperature : 50 oC

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running

- H2O2 was added

- The process was Continued for 20 min at a temperature of 50 oC

|

| Fig: Flow diagram of bleach wash |

After drop the liquor, the bleach wash garments turned to Hydro extractor machine to remove excessive water from the garments.

Step 5: Drying

After hydro extraction the garments are turned to drying machine for better drying. This process continued for 15 minutes.

4.3.2 Enzyme wash:

Step 1: Desizing

Recipe:

- Soda ash : 250gm

- Antistant : 50gm

- Time : 15min

- Temperature : 600c.

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Soda ash was added.

- Antistant was added.

- The process was continued for 15 min at a temperature of 600c.

- Then the liquor was dropped.

|

| Fig: Flow diagram of desizing |

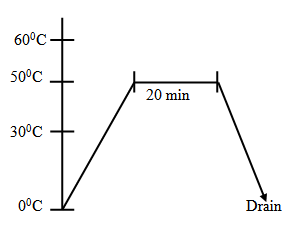

Recipe:

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 450C

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Acetic acid was added.

- Antistant was added.

- Powder enzyme was added.

- Then liquid enzyme was added.

|

| Fig: Flow diagram of enzyme wash |

After drop the liquor, the enzyme wash garments turned to Hydro extractor machine to remove excessive water from the garments

Step 4: Drying

After hydro extraction the garments are turned to drying machine for better drying. This process continued for 15 minutes.

|

| Fig-7: Enzyme wash |