Now You Know Basic Tests of Textile Fabric

Monday, 4 February 2019

Edit

Basic Tests of Textile Fabric

Shabuz Biplob

Manager of Quality Assurance & Technical Support in a Buying House

Mobile: +8801617 225544 (Viber)

Office: +8801511 779988

Skype: shabuzbiplob1

E-mail: shabuz.biplob@yahoo.com

Shabuz Biplob

Manager of Quality Assurance & Technical Support in a Buying House

Mobile: +8801617 225544 (Viber)

Office: +8801511 779988

Skype: shabuzbiplob1

E-mail: shabuz.biplob@yahoo.com

Today I’m writing about Basic Tests of Textile Fabric, although these tests are different depending on buyers’ requirements & it needs a vast discussion. But I’ll discuss on very basic things shortly for only garments probationers. Please keep in mind what I wanted to say in my previous writings, there are so many ways here to perform a job, through day by day practices, you’ll find the easiest way for you to do your job well.

A. Tests for General Fabric Information:

Following tests are used to gain general fabric info. See the list below for what we need know for General Fabric Testing.

1. Fiber Content Test: The test is required to know the content or ingredient of provided fabric. Following info is required during this test method.

- Single Fiber (A fiber contains one ingredient only)

- Blended Fiber (A fiber consists of more than one ingredients)

- GSM (We usually count GSM for knitted fabrics; it means Grams per Square Meter).

|

| GSM cutter |

|

| GSM checking machne |

- Oz (We usually use it for woven fabrics; it means Ounce per Square Yards).

4. Threads per unit length (Used to identify the knitting way)

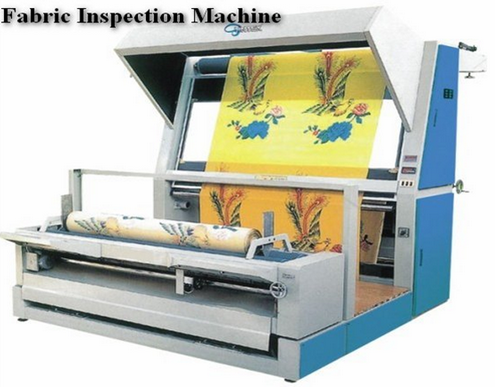

5. Defects (Mostly used 4 point system to identify visual defects of fabric, it’s called fabric inspection).

For 4 point system, fabrics are taken as per below table for inspection by factories’ QCs (Quality Controllers). It shows the percentage of fabric, a QC should take the amount for his fabric inspection as per fabric packing list.

| Yards received as per packing list | Percentage |

| 1 - 2500 | 20% |

| 2501 - 5000 | 10% |

| 5001 - 20,000 | 8% |

| 20,001 - 30,000 | 6 % |

| 30,001 - 50,000 | 4% |

Penalty points are given as per following table. During Fabric Inspection, A QC needs keep in mind that a hole on fabric usually gets 4 point. Maximum 4 points can be charged for 1 linear yard. Acceptance is 40 points per 100 yards. Sometimes it depends on buyer’s requirement.

Formula: Total defects points / Fabric length in yards X 36 / Fabric Width X 100

Formula: Total defects points / Fabric length in yards X 36 / Fabric Width X 100

| Inches | Points |

| From 1 to 3 inches | 1 |

| Above 3 to 6 inches | 2 |

| Above 6 to 9 inches | 3 |

| Above 9 to 36 inches | 4 |

|

| Fabric inspection machine |

B. Dimensional Stability (DS):

Supposed, you bought a shirt from a shop as per your required size. But after washing, it became smaller or larger than your required size. Then you’ll be upset. So, to avoid this problem, fabric requires Dimensional Stability Test. Please note, below topics belongs to dimensional Stability Test.

Shrinkage % = Before Wash - After Wash / Before Wash x 100

Twisting % = After Wash Twist Measurement / Total Length x 100

Supposed, you bought a shirt from a shop as per your required size. But after washing, it became smaller or larger than your required size. Then you’ll be upset. So, to avoid this problem, fabric requires Dimensional Stability Test. Please note, below topics belongs to dimensional Stability Test.

- DS to Washing (shrinkage) (needs for checking measurements of garment after washing)

- DS to Dry Cleaning (needs to check measurements of garment after dry cleaning)

- Spirality / Skew / Torque (requires to check twisted deformation of garments after dry cleaning & washing)

- Garments Appearance after Washing / Dry Cleaning (requires to check shape of garments after wash)

Shrinkage % = Before Wash - After Wash / Before Wash x 100

Twisting % = After Wash Twist Measurement / Total Length x 100

|

| Photo of Garment Shrinkage after Wash |

|

| Textile washing machine |

C. Color Fastness (CF):

Color Fastness Test is undertaken to measure the level of fading or bleeding that occurs on garments with factors like washing, ironing, lights, rubbing etc. Below are the main ones that are standardized. The light fastness of textile dye is categorized from one to eight and the wash fastness from one to five. Please note, the higher the number the better fastness is obtained.

D. Physical Characteristics:

It’s a qualitative or quantitative procedure that consists of determination of one or more characteristics of a fabric, process or service according to a specified procedure. It’s obviously a major part of fabric experiment. Following topics are done during Fabric’s Physical Characteristics Test:

1. Tensile strength (used to realize the tensility of fabric)

2. Tearing strength (used to realize the tearing strength of fabric)

3. Bursting Strength (used to realize the bursting strength of fabric)

4. Pilling resistance (used to realize the pilling resistance of fabric)

5. Abrasion resistance (used to realize the abrasion resistance of fabric)

6. Seam Slippage (In this case, a 75 mm wide fabric specimens are held in screw grips and the force is measured when the seam separates by a defined distance. The force-travel diagrams of a seamed and a seamless reference test specimen of the same material are then compared).

7. Recovery Test (It refers the power of fabric to come its original form or shape after stretched)

8. Water Repellency (To observe the level of water repellency of water proof finished goods)

9. pH Value (pH is a measure of the acidity or basicity of an aqueous solution. The pH scale measures how acidic or basic a substance is. The pH scale ranges from 0 to 14. A pH of 7 is neutral. The pH less than 7 is acidic. The pH greater than 7 is basic).

10. Pile Loss (This test method covers the determination of the abrasion of pile fabrics when the loss of pile stuffs occur, sometimes called pile retention or pile pull out).

In some cases, more basic tests are required depending on buyers’ requirements such as flammability, fill power, harmful chemicals & heavy metal content etc. Today I’m going to finish here. Hope, we’ll meet soon with more. Before leaving, please pardon me for finding anything boring in my writings. Thank you for reading with patience.

Color Fastness Test is undertaken to measure the level of fading or bleeding that occurs on garments with factors like washing, ironing, lights, rubbing etc. Below are the main ones that are standardized. The light fastness of textile dye is categorized from one to eight and the wash fastness from one to five. Please note, the higher the number the better fastness is obtained.

- Color Fastness to Washing (used to measure color bleeding or fading after wash)

- Color Fastness to Dry Cleaning (used to measure color bleeding or fading after dry cleaning)

- Color Fastness to Ironing (used to measure color bleeding or fading after ironing)

- Color Fastness to Water (used to measure color bleeding or fading into water)

- Color Fastness to Rubbing (used to measure color bleeding or fading after rubbing)

- Color Fastness to Perspiration (used to measure color bleeding or fading into perspiration)

- Color Fastness to Light (used to measure color bleeding or fading into light)

- Color Fastness to Chlorine Bleach (used to measure color bleeding or fading while chlorine bleaching)

|

| Photo of Color Fastness before & after Wash |

It’s a qualitative or quantitative procedure that consists of determination of one or more characteristics of a fabric, process or service according to a specified procedure. It’s obviously a major part of fabric experiment. Following topics are done during Fabric’s Physical Characteristics Test:

1. Tensile strength (used to realize the tensility of fabric)

2. Tearing strength (used to realize the tearing strength of fabric)

3. Bursting Strength (used to realize the bursting strength of fabric)

4. Pilling resistance (used to realize the pilling resistance of fabric)

5. Abrasion resistance (used to realize the abrasion resistance of fabric)

6. Seam Slippage (In this case, a 75 mm wide fabric specimens are held in screw grips and the force is measured when the seam separates by a defined distance. The force-travel diagrams of a seamed and a seamless reference test specimen of the same material are then compared).

7. Recovery Test (It refers the power of fabric to come its original form or shape after stretched)

8. Water Repellency (To observe the level of water repellency of water proof finished goods)

9. pH Value (pH is a measure of the acidity or basicity of an aqueous solution. The pH scale measures how acidic or basic a substance is. The pH scale ranges from 0 to 14. A pH of 7 is neutral. The pH less than 7 is acidic. The pH greater than 7 is basic).

10. Pile Loss (This test method covers the determination of the abrasion of pile fabrics when the loss of pile stuffs occur, sometimes called pile retention or pile pull out).

|

| Photo of pile fabrics |