Now You Know Garment Washing: An Effective Process for Beautification of Garments (Part-5)

Monday, 4 February 2019

Edit

Garment Washing: An Effective Process for Beautification of Garments (Part-5)

Rahat Khan

Dept. of Apparel Manufacturing

Atish Dipankar University of Science and Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Dept. of Apparel Manufacturing

Atish Dipankar University of Science and Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

4.3.6 Hand whicker:

Hand whickering is the wash where after washing the garments, the garments are brushed with emery paper by hand placing on a pattern made by using wire or pipe on wooden board.

Step 1: Desizing

Recipe:

- Soda ash : 250gm

- Antistant : 50gm

- Time : 15min

- Temperature : 600c

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Soda ash was added.

- Antistant was added.

- The process was continued for 15 min at a temperature of 600c.

- Then the liquor was dropped

|

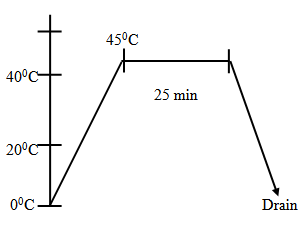

| Fig: Flow diagram of desizing |

Recipe:

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 450c

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Acetic acid was added.

- Antistant was added.

- Powder enzyme was added.

- Then liquid enzyme was added.

- The process was continued for 25 min at a temperature of 450c.

- Then the liquor was dropped

|

| Fig: Flow diagram of enzyme wash |

After drop the liquor, the hand whicker wash garments turned to Hydro extractor machine to remove excessive water from the garments

Step 4: Drying

After hydro extraction the garments were turned to drying machine for better drying. This process continued for 15 minutes.

Step 5: Hand whickering

After washing the garments was placed on a pattern (It is a design made by using wire/pipe on a wooden board) then brush it with emery paper by hand.

Step 6: Normal wash

It was done by normal water for 5 minutes

Step 7: Hydro extraction

After drop the liquor, the hand whicker wash garments turned to Hydro extractor machine to remove excessive water from the garments

Step 8: Drying

After hydro extraction the garments were turned to drying machine for better drying. This process continued for 15 minutes.

|

| Fig-11: Hand whicker Fig-12: This pattern has been used for hand whicker |

Pattern whickering is a type of wash where after washing, the garment was placed on a pattern (It is a design made by using rubber pattern) then sand blasting is done in the pattern area using sand gun

Step 1: Desizing

Recipe:

- Soda ash : 250gm

- Antistant : 50gm

- Time : 15min

- Temperature : 600c

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Soda ash was added.

- Antistant was added.

- The process was continued for 15 min at a temperature of 600c.

- Then the liquor was dropped

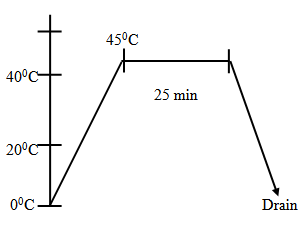

|

| Fig: Flow diagram of desizing |

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 450c

A lot size of 5 kg garments was considered. Water was added at the rate of 1:5 liquor ratio i.e. 25 kg water.

- At first the machine was started running.

- Acetic acid was added.

- Antistant was added.

- Powder enzyme was added.

- Then liquid enzyme was added.

- The process was continued for 25 min at a temperature of 450c.

- Then the liquor was dropped

|

| Fig: Flow diagram of enzyme wash |

After drop the liquor, the hand whicker wash garments turned to Hydro extractor machine to remove excessive water from the garments

Step 4: Drying

After hydro extraction the garments are turned to drying machine for better drying. This process continued for 15 minutes.

Step 5: pattern whickering

After washing, the garment was placed on a pattern (It is a design made by using rubber pattern) then sand blasting is done in the pattern area using sand gun.

Step 6: Normal wash

It was done by normal water for 5 minutes

Step 7: Hydro extraction

Hydro extractor was used to remove excessive water from the garments.

After hydro extraction the garments were turned to drying machine for better drying. This process continued for 15 minutes.

|

| Fig-13: Pattern whicker Fig-14: Use this pattern for pattern whicker |