Yaa Garment Washing: An Effective Procedure For Beautification Of Garments (Part-2)

Wednesday, 19 December 2018

Edit

Garment Washing: An Effective Process for Beautification of Garments (Part-2)

Rahat Khan

Dept. of Apparel Manufacturing

Atish Dipankar University of Science as well as Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Dept. of Apparel Manufacturing

Atish Dipankar University of Science as well as Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Previous Part

2.3.1 Garments washing machine:

The principal utilization of garments washing machine is to take away the Starch as well as to brand the garments soft. If whatever dirt is generated inwards the stuff surface it tin privy live removed past times washing. It gives garments novel outlook.

Specification of machine:

2.3.2 Hydro extractor:

Hydro extractor is used to take away excessive H2O from the garments. Knitted fabrics should non live squeezed inwards pressure level mangles. Hydro extractor is used for such form of fabrics to take away excess H2O earlier larn for drying. Hydro extraction is a batch procedure which works on centrifuge principle. Fabrics set into the perforated case, made for copper or galvanized iron, which is mounted on a fundamental spindle as well as contained inwards steel or atomic set out 26 casing. When the perforated casing rotates at high speed, a centrifugal forcefulness is developed which forces the moisture fabrics to the inner wall of the case. Water is as well as thus forced out from the fabrics through the perforation of the casing. It is the best procedure for removing H2O giving the nigh efficiency.

2.3.3 Drying machine:

After hydro extraction the garments are turned to drying machine for meliorate drying .Tumble dryer is peculiarly used for garments drying. Here the fabrics are dried at maximum ease state. That’s why shrinkage as well as GSM tin privy live controlled.

2.3.4 Boiler:

Boiler is an essential machine, which is used inwards dyeing & washing industries to create steam from water. It contains huge total of H2O inwards it as well as convert those H2O inwards to steam to enhance temperature.

The equipment used for producing steam is called steam generator or boiler. The boiler used for producing steam inwards IAL is Cochran boiler which is a sack underground type boiler. Simple vertical boiler of sack underground type is mainly used inwards pocket-size found requiring pocket-size quantity of steam as well as where flooring expanse is limited.

Here, gas is fed to the burner which run past times thermo motor as well as create flame. The open fire produces hot flue gases, which transcend through the tubes that are surrounded past times water. This H2O is supplied from the soft H2O tank to the feed H2O tank, which is situated higher upwards the boiler. The oestrus unloose energy of the flue gas is transfer to H2O which is converted into steam. This steam is supplied to the whole plant. The spent gases are as well as thus discharged to the atmosphere through chimney.

2.3.5 Sample washing machine:

After getting social club from buyer, sample is prepared every bit per buyers’ requirement to gibe the master copy sample. Before volume production this is done inwards sample washing machine.

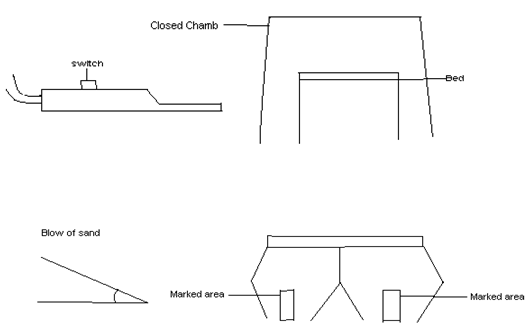

2.3.6 Sand blasting unit:

It is a mechanical procedure of producing fading trial on garments made from heavy stuff similar denim. Normally sand blasting is combined amongst launder similar normal wash, bleach wash, enzyme launder & over dyeing.

The procedure of sand blasting is described below:

Aluminum oxide is used for sand blasting which looks similar sand .This aluminum oxide are blown at real high pressure level through a gun .The gun has a switch to showtime as well as halt period of time of aluminum oxide .The garments to live sand blasted are placed on the bed of a unopen bedroom .From feeding bedroom sands are blown past times high air pressure level through the pipage as well as gun .The expanse of the garments fabrics surface is faded past times the friction comport on of sand .The blow of sand is placed at 10-20 angle on surface .Fading is done on re marked areas .Various patterns or designs may live used during fading creation inwards the pre marked areas past times blocking or fading technique .The faded garments are manually cleaned past times shaking as well as kept aside

3.1 Sample preparation:

Denim:

Denim is a strong, durable stuff constructed inwards a twill weave amongst indigo as well as white yarns. The bluish or indigo yarns are the length wise or “warp” threads (parallel to the selvedge). The white yarns come across the stuff width (the weft threads). Denim is traditionally woven amongst 100% cotton wool yarn; however, today it is blended amongst polyester, to command shrinkage & wrinkles, as well as lycra to add together stretch.

Today, denim has many faces. It tin privy live printed, striped, brushed, napped & rock washed, as well as the indigo bluish yarn tin privy live replaced amongst unlike colors’ to practice colored denim.

3.2 Denim stuff analysis:

By analyzing the denim stuff amongst counter drinking glass & needle nosotros discovery that it is a ii upwards 1 downward twill weave fabric.

Fabric composition:

1. Warp: 100% cotton wool

2. Weft:

The principal utilization of garments washing machine is to take away the Starch as well as to brand the garments soft. If whatever dirt is generated inwards the stuff surface it tin privy live removed past times washing. It gives garments novel outlook.

|

| Fig-1: Vertical washing machine |

|

| Fig-2: Horizontal washing machine |

- Capacity: 500kg (weight of garments)

- Normal capacity: 200kg

- Dia of principal cylinder: 4-6 inch

- Height of the bar: 4inch

- Cylinder rpm: 30-40

- M: L: 1:5 to 1:10

2.3.2 Hydro extractor:

Hydro extractor is used to take away excessive H2O from the garments. Knitted fabrics should non live squeezed inwards pressure level mangles. Hydro extractor is used for such form of fabrics to take away excess H2O earlier larn for drying. Hydro extraction is a batch procedure which works on centrifuge principle. Fabrics set into the perforated case, made for copper or galvanized iron, which is mounted on a fundamental spindle as well as contained inwards steel or atomic set out 26 casing. When the perforated casing rotates at high speed, a centrifugal forcefulness is developed which forces the moisture fabrics to the inner wall of the case. Water is as well as thus forced out from the fabrics through the perforation of the casing. It is the best procedure for removing H2O giving the nigh efficiency.

|

| Fig-3: Hydro extractor |

After hydro extraction the garments are turned to drying machine for meliorate drying .Tumble dryer is peculiarly used for garments drying. Here the fabrics are dried at maximum ease state. That’s why shrinkage as well as GSM tin privy live controlled.

2.3.4 Boiler:

Boiler is an essential machine, which is used inwards dyeing & washing industries to create steam from water. It contains huge total of H2O inwards it as well as convert those H2O inwards to steam to enhance temperature.

The equipment used for producing steam is called steam generator or boiler. The boiler used for producing steam inwards IAL is Cochran boiler which is a sack underground type boiler. Simple vertical boiler of sack underground type is mainly used inwards pocket-size found requiring pocket-size quantity of steam as well as where flooring expanse is limited.

Here, gas is fed to the burner which run past times thermo motor as well as create flame. The open fire produces hot flue gases, which transcend through the tubes that are surrounded past times water. This H2O is supplied from the soft H2O tank to the feed H2O tank, which is situated higher upwards the boiler. The oestrus unloose energy of the flue gas is transfer to H2O which is converted into steam. This steam is supplied to the whole plant. The spent gases are as well as thus discharged to the atmosphere through chimney.

2.3.5 Sample washing machine:

After getting social club from buyer, sample is prepared every bit per buyers’ requirement to gibe the master copy sample. Before volume production this is done inwards sample washing machine.

|

| Fig-4: Sample washing machine |

It is a mechanical procedure of producing fading trial on garments made from heavy stuff similar denim. Normally sand blasting is combined amongst launder similar normal wash, bleach wash, enzyme launder & over dyeing.

|

| Fig-5: Sand blasting unit of measurement |

Aluminum oxide is used for sand blasting which looks similar sand .This aluminum oxide are blown at real high pressure level through a gun .The gun has a switch to showtime as well as halt period of time of aluminum oxide .The garments to live sand blasted are placed on the bed of a unopen bedroom .From feeding bedroom sands are blown past times high air pressure level through the pipage as well as gun .The expanse of the garments fabrics surface is faded past times the friction comport on of sand .The blow of sand is placed at 10-20 angle on surface .Fading is done on re marked areas .Various patterns or designs may live used during fading creation inwards the pre marked areas past times blocking or fading technique .The faded garments are manually cleaned past times shaking as well as kept aside

|

| The procedure of sand blasting |

Chapter three

Research methodology

Research methodology

3.1 Sample preparation:

Denim:

Denim is a strong, durable stuff constructed inwards a twill weave amongst indigo as well as white yarns. The bluish or indigo yarns are the length wise or “warp” threads (parallel to the selvedge). The white yarns come across the stuff width (the weft threads). Denim is traditionally woven amongst 100% cotton wool yarn; however, today it is blended amongst polyester, to command shrinkage & wrinkles, as well as lycra to add together stretch.

Today, denim has many faces. It tin privy live printed, striped, brushed, napped & rock washed, as well as the indigo bluish yarn tin privy live replaced amongst unlike colors’ to practice colored denim.

3.2 Denim stuff analysis:

By analyzing the denim stuff amongst counter drinking glass & needle nosotros discovery that it is a ii upwards 1 downward twill weave fabric.

|

| Fig: Denim stuff sample |

1. Warp: 100% cotton wool

2. Weft:

- Cotton: 76%

- Polyester: 23%

- Spandex: 1%

- Total: 10