Yaa Report On The Garments Washing Together With Dyeing Machine

Thursday, 20 December 2018

Edit

Study on the Garments Washing & Dyeing Machine

Sajib Barman

Department of Textile technology scientific discipline

World University of Bangladesh

Email: sajibbarman30@gmail.com

Contact: +8801670742864

Sajib Barman

Department of Textile technology scientific discipline

World University of Bangladesh

Email: sajibbarman30@gmail.com

Contact: +8801670742864

Introduction:

For to a greater extent than than concluding threescore years, continuous question in addition to evolution is going on garments dyeing technique, physical care for in addition to machines. Various types of garments dyeing machines convey been developed in addition to all those garments dyeing machines tin flame move classified into next 2 groups:

- Paddle dyeing machine

- Rotary drum dyeing machine

- Lower liquor ratio inward garments dyeing requires lower water, steam, in addition to chemic consumption, so lower garments dyeing cost.

|

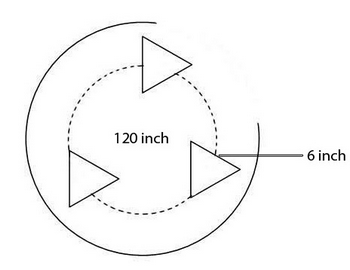

| Fig: Schematic diagram of an industrial washing in addition to dyeing machine |

|

| Fig: Sectional persuasion of an industrial garments washing machine. |

- Made of stainless steel.

- There are 2 large circular cylinders.

- Outer cylinder is made of company stainless steel.

- Inner cylinder is perforated in addition to every bit good made of stainless steel.

- A sliding door is used to charge in addition to unload materials.

- There are chemic dozing doors.

- Outer cylinder is fixed amongst the machine frame.

- Inner cylinder is placed inside the outer cylinder past times shaft.

- Inner cylinder is related past times motor pulley in addition to belt drive from both side.

- Auto reversel unit of measurement assistance inward duel administration of the cylinder rotation.

- Duel administration is necessary for avoiding roping.

- there are 3 bars at 120° apart well-nigh 6˝ elevation inward the inner cylinder.

- There is a gap well-nigh 4˝ betwixt outer in addition to inner cylinder.

- A drinking glass metro is connected to the outer cylinder.

- There is a pannel board inward a higher house the machine to command about machine operating parameters.

A physical care for of dyeing textiles inward a machine that gently displace the goods using paddles similar to a paddle cycle on a boat. This is a tiresome process, but at that spot is extremely trivial abrasion on the goods. Horizontal Paddle Machines (over caput paddle machine) consist of a curved beck similar lower suction to incorporate the materials in addition to the dye liquor. The goods are moved past times a rotating paddle, which extends across the width of the machine. Half immersed paddles crusade the fabric to displace upwards in addition to downwards throughout the liquor.

The temperature tin flame move raised to 98o C inward such system.Lateral / oval paddle machines consist of oval tank to heighten the fluid catamenia in addition to the processing the goods. In the middle of this tank is a shut oval island. The paddle moves inward a lateral administration in addition to is non one-half submerged inward the liquor in addition to the temperature tin flame move increased upwards to 98 C.HT Paddle Machines move according to the regulation of horizontal paddle machine; however, the temperature tin flame move raised upwards to 140 C. PES articles are preferably dyed on HT paddles.

In paddle machines, the dyeing tin flame move carried out amongst 30:1 to 40:1, lower ratios reduces optimum movement of the goods, atomic number 82 to unlevel dyeing, bend formation. For gentleness, the blades of the paddle are either curved or convey rounded edges in addition to the rotating speed of the paddle tin flame move regulated from 1.5 to twoscore rpm. Circulation of the liquor should move rigid plenty to forbid goods from sinking to the bottom. Paddle machines are suitable for dyeing articles of all substrates inward all forms of brand ups. The goods are commonly dyed using PP/PET bags.

Conclusion:

In this experiment, nosotros tin flame know that which the working physical care for of Industrial dyeing in addition to washing machine. It is really helpful inward our futurity life when nosotros are working inward textile industry.

Conclusion:

In this experiment, nosotros tin flame know that which the working physical care for of Industrial dyeing in addition to washing machine. It is really helpful inward our futurity life when nosotros are working inward textile industry.

You tin flame every bit good like:

- Types of Dyeing Machine

- Study on Different Laboratory Equipments of a Modern Dye House

- Study on the Garments Washing in addition to Dyeing Machine

- Hydro Extractor | Advantages of Hydro Extractor inward Textile Finishing Process

- Working Principle of HTHP Beaker Dyeing Machine

- Working Process of Skein Dyeing Machine

- Working Process of Winch Dyeing Machines

- Specification of Printing Machineries

- Working Process of Jigger Dyeing Machine

- Working Procdure of Roller Printing

- List of Dyeing Machineries/Printing Machineries/Finishing Machineries

- Working Process of Package Dyeing Machine

- Working Process of Roller Hank Dyeing Machines

- Soft Flow Dyeing Machine in addition to Principle of Soft Flow Dyeing Machine