Yaa Garment Washing: An Effective Procedure For Beautification Of Garments (Part-4)

Wednesday, 19 December 2018

Edit

Garment Washing: An Effective Process for Beautification of Garments (Part-4)

Rahat Khan

Dept. of Apparel Manufacturing

Atish Dipankar University of Science in addition to Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Dept. of Apparel Manufacturing

Atish Dipankar University of Science in addition to Technology

Cell: +8801717781833

Email: rahat.info@gmail.com

Previous Part

4.3.3 Stone enzyme wash:

Step 1: Desizing

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

Step 2: Enzyme launder

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

Step 3: Hydro extraction

After drib the liquor, the rock enzyme launder garments turned to Hydro extractor machine to take away excessive H2O from the garments

Step 4: Drying

After hydro extraction the garments are turned to drying machine for improve drying. This procedure continued for xv minutes.

4.3.4 Light wash:

Step 1: Desizing

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

Step 2: Enzyme launder

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

Step 3: Bleach wash:

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg H2O

Step 4: Hydro extraction

After drib the liquor, the calorie-free launder garments turned to Hydro extractor machine to take away excessive H2O from the garments

Step 5: Drying

After hydro extraction the garments are turned to drying machine for improve drying. This procedure continued for xv minutes.

4.3.5 Potassium permanganate:

Step 1: Desizing

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

Step 2: Enzyme launder

Recipe:

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

Step 3: Spray

Spray amongst potassium permanganate equally per required depth of shade

Step 4: Tinting

After drib the liquor, the Potassium permanganate launder garments turned to Hydro extractor machine to take away excessive H2O from the garments

Step 6: Drying

After hydro extraction the garments were turned to drying machine for improve drying. This procedure continued for xv minutes.

4.3.3 Stone enzyme wash:

Step 1: Desizing

Recipe:

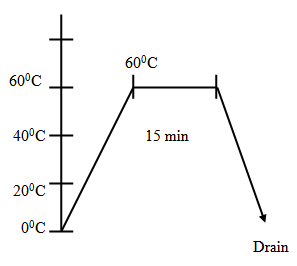

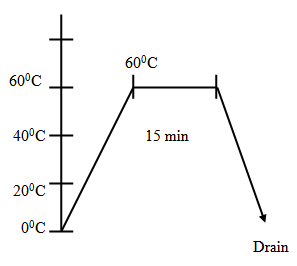

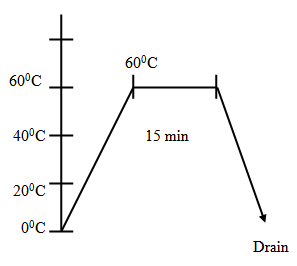

- Soda ash : 250gm

- Antistant : 50gm

- Time : 15min

- Temperature : sixty oc

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

- At commencement the machine was started running.

- Soda ash was added.

- Antistant was added.

- The procedure was continued for xv min at a temperature of 600c.

- Then the liquor was dropped.

|

| Fig: Flow diagram of desizing |

Recipe:

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 450C

- Pneumic rock : seven to ten kg (Depending on garments weight)

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

- At commencement the machine was started running.

- Acetic acid was added.

- Antistant was added.

- Powder enzyme was added.

- Then liquid enzyme was added.

- The procedure was continued for 25 min at a temperature of 450c.

- Then the liquor was dropped

|

| Fig: Flow diagram of enzyme launder |

After drib the liquor, the rock enzyme launder garments turned to Hydro extractor machine to take away excessive H2O from the garments

Step 4: Drying

After hydro extraction the garments are turned to drying machine for improve drying. This procedure continued for xv minutes.

|

| Fig-8: Stone enzyme launder |

Step 1: Desizing

Recipe:

- Soda ash : 250gm

- Antistant : 50gm

- Time : 15min

- Temperature : 600C

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

- At commencement the machine was started running.

- Soda ash was added.

- Antistant was added.

- The procedure was continued for xv min at a temperature of 600c.

- Then the liquor was dropped

|

| Fig: Flow diagram of desizing |

Recipe:

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 450c.

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

- At commencement the machine was started running.

- Acetic acid was added.

- Antistant was added.

- Powder enzyme was added.

- Then liquid enzyme was added.

- The procedure was continued for 25 min at a temperature of 450c.

- Then the liquor was dropped

|

| Fig: Flow diagram of enzyme launder |

Recipe:

- Stabilizer : 200gm

- H2O2 : 500gm

- Temperature : 200C

- Time : As required

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg H2O

- At commencement the machine was started running.

- Stabilizer was added

- H2O2 was added

- The procedure was Continued for required fourth dimension at a temperature of 200C

|

| Fig: Flow diagram of bleach launder |

After drib the liquor, the calorie-free launder garments turned to Hydro extractor machine to take away excessive H2O from the garments

Step 5: Drying

After hydro extraction the garments are turned to drying machine for improve drying. This procedure continued for xv minutes.

|

| Fig-9: Light launder |

Step 1: Desizing

Recipe:

- Soda ash : 250gm

- Antistant : 50gm

- Time : 15min

- Temperature : 60ْc

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

- At commencement the machine was started running.

- Soda ash was added.

- Antistant was added.

- The procedure was continued for xv min at a temperature of 600c.

- Then the liquor was dropped

|

| Fig: Flow diagram of desizing |

Recipe:

- Acetic acid : 20gm

- Antistant : 20gm

- Powder enzyme : 200gm

- Liquid enzyme : 150gm

- Time : 25min

- Temperature : 45 oC

A lot size of v kg garments was considered. Water was added at the charge per unit of measurement of 1:5 liquor ratio i.e. 25 kg water.

- At commencement the machine was started running.

- Acetic acid was added.

- Antistant was added.

- Powder enzyme was added.

- Then liquid enzyme was added.

- The procedure was continued for 25 min at a temperature of 450c.

- Then the liquor was dropped

|

| Fig: Flow diagram of enzyme launder |

Spray amongst potassium permanganate equally per required depth of shade

Step 4: Tinting

- Brown color (reactive dye) : 0.001 gm

- Salt : 500gm

- Temperature : 500C

- Time : 15min

After drib the liquor, the Potassium permanganate launder garments turned to Hydro extractor machine to take away excessive H2O from the garments

Step 6: Drying

After hydro extraction the garments were turned to drying machine for improve drying. This procedure continued for xv minutes.

|

| Fig-10: Potassium permanganate |