Yaa Report On Dissimilar Laboratory Equipments Of A Modern Dye House

Wednesday, 19 December 2018

Edit

Study on Different Laboratory Equipments of a Modern Dye House

Rofiquzzaman Raju

Chittagong Textile Engineering College

Contact: 01714419781

Email: rtextile.finance@gmail.com

Chittagong Textile Engineering College

Contact: 01714419781

Email: rtextile.finance@gmail.com

Introduction:

Satisfaction of client demands is the character of a product. It is the extent of excellence of a production that indicates that whether it meets the client ultimate need or not. As textiles, an integrated news is related to dissimilar segments as well as each segment is responsible to encounter upward the requirements of subsequent segments as well as lastly the ultimate user. Dyeing, the physical care for of coloring textile materials alongside or thence medium. It is the department inwards which raw fabrics are dyed alongside coloring materials i.e. dyes inwards or thence medium i.e. H2O along alongside several chemicals. Fabrics are colored every bit per the buyer requirements. Before going to the mass production, a sample cloth is dyed inwards the dyeing lab. If the desired shade is produced hither as well as thence it is become for mass production at large amount. However, primary recipe to prepare detail shade is prepared hither as well as and thence lastly implemented inwards the production section. H5N1 touchstone character lab provides all opportunities to create detail shade without whatever disturbance. Besides, the dissimilar tests are done inwards the physical lab to evaluate the dissimilar parameters of dyed fabric. Tests conducted inwards the physical lab basically based on the buyer requirements. During testing, dissimilar types of testing method are followed which is varied from buyer to buyer. To acquire this, an observation was done at ECHO-TEX LIMITED; an export oriented clothes manufacture produces all types of knitting garments. In this article, give-and-take volition live done on dyeing lab of that factory.

Objects:

Name of the Machine Used inwards Chemical Lab:

Machine No.01 as well as 02

Specification of the machine:

Function: To dye lab dip based on buyer requirements.

Machine No. 03

Specification of the machine:

Function: To dye lab dip.

Machine No.04

Specification of the machine:

Function: Treating the cloth sample alongside H2O to create upward one's hear color fastness to washing.

Machine No.05

Specification of the machine:

Function: Exposing the cloth sample to create upward one's hear color fastness to light.

Machine No.06

Specification of the machine:

Function: To dry out cloth sample at required sample.

Machine No.07

Specification of the machine:

Function: To launder the cloth sample at detail temperature.

Machine No.08

Specification of the machine:

Function: To launder the cloth sample rattling quick vogue alongside honour to normal washing.

Machine No.09

Specification of the machine

Function: After dyeing soaping is done past times this machine.

Machine No.10

Specification of the machine:

Function: To prepare dye solution based on recipe sum for dyeing.

Machine No.11

Specification of the machine:

Function:

Objects:

- To know the dissimilar chemicals as well as equipments used inwards the dyeing lab.

- To empathize close the dissimilar exam carried out inwards the physical lab.

- To know the responsibleness of dissimilar managerial designation inwards the dyeing lab.

- Understanding the business office of dissimilar machineries used inwards dyeing lab.

- Name of the Project: ECHOTEX LTD.

- Location: Chandra pallibidyut, Kaliakoir, Gazipur.

- Established year: 2003

- Status:100% Export Oriented Knit composite

- Project toll : TK. 2500 crore

- Production capacity: 2100000 pcs/month

- Man power: 7000 people

|

| Figure: Layout of Dyeing lab of ECHO-TEX Limited (Click on picture for large size) |

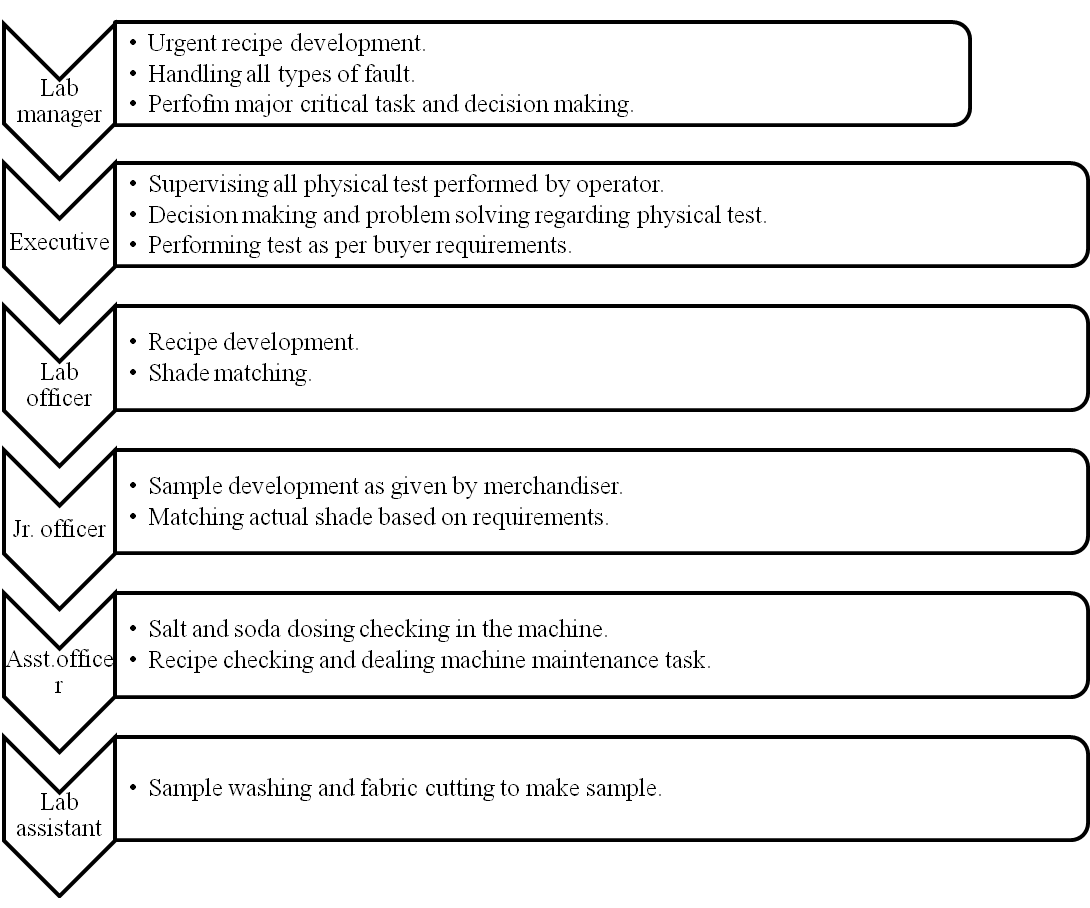

Management construction as well as their responsibleness of the dyeing lab:

Types of Dyeing lab:-

|

| Management construction as well as their responsibleness of the dyeing lab (Click on picture for large size) |

|

| Types of Dyeing lab |

Machine No.01 as well as 02

Specification of the machine:

- Name: Sample dyeing machine

- Brand Name: Datacolor AHIBA IRTM

- Origin : U southward H5N1

- No. of pot: xix

- Heating system: Infrared

- Sample wt. =5gm

|

| Fig: Sample dyeing machine |

Machine No. 03

Specification of the machine:

- Name: Sample dyeing machine

- Brand Name: Mathis LABOMAT

- Origin: Switzerland

- No.of pot: 23

- Heating system: Infrared

- Sample wt. =10gm

|

| Fig: Sample dyeing machine |

Machine No.04

Specification of the machine:

- Name: Rotawash machine:

- Brand: SDL International

- Model: M228

- Origin: England

- No. of pot: 8

|

| Fig: Rota launder machine |

Machine No.05

Specification of the machine:

- Name: Lord's Day exam CPS+ machine

- Brand: SDL International

- Origin: England

- Lamp capacity=500W

|

| Fig: Lord's Day exam CPS+ machine |

Machine No.06

Specification of the machine:

- Name: Oven dryer machine

- Specification:

- Brand: XIEMAN Rapid

- Origin: mainland People's Republic of China

|

| Fig: Oven dryer machine. |

Machine No.07

Specification of the machine:

- Name: Washing machine

- Brand: SIEMENS

- Origin: Deutschland

- Capacity: 5.5 kg

- Speed: 1000rpm

|

| Fig: Washing machine |

Machine No.08

Specification of the machine:

- Name: Quick launder addition machine:

- Specification:

- Brand: SDLATLAS

- Origin: UK of Britain as well as Northern Republic of Ireland

|

| Fig: Quick launder addition washing machine |

Machine No.09

Specification of the machine

- Name: Shaker machine

- Specification:

- Brand: Rapid

- Origin: mainland People's Republic of China

|

| Fig: Shaker machine |

Machine No.10

Specification of the machine:

- Name: Robolab machine

|

| Fig: Rob lab machine |

Machine No.11

Specification of the machine:

- Name: Spectrophotometer machine

- Model: 650

- Origin: USA

|

| Fig: Spectrophometer machine |

- Recipe prepare from touchstone sample

- Check CMC value of Sample to evaluate it.

Tests done inwards Physical lab are:

- Dimensional stability.

- Shrinkage

- Spirality

- Angular spacing

- Pilling exam

- Rubbing Test

- GSM

- Color fastness to lite

- Color fastness to H2O

- Color fastness to washing

- Color fastness to perspiration ( Acid & Alkali Solution)

- Color fastness to SALIVA

- Color fastness Phenolic Uline

Specification of the machine:

- Name: Pilling tester

- Brand: SDL ATLAS

- Origin: UK of Britain as well as Northern Republic of Ireland

|

| Fig: Pilling tester machine |

Testing parameters:

- Sample size: (12.5 x 12.5) cm,Method: ISO 12945-1:2001

- Tube size: (14 x 2.6) cm,Revolution: 14400

- Speed: threescore rpm,Test sample: iv pcs

- Course wise: ii pcs as well as Wales wise: ii pcs

Specification of the machine:

Name: Crockmeter

Test parameters:

- Sample size: Dyed cloth – (14 x5) cm

- White Test Cloth - v cm ´ v cm

- Method: ISO 105x2L: 2002

- Revolution: 10cycle/10sec

- Weight: 9N

|

| Figure: Crockmeter |

Machine No.03

Specification of the machine:

- Name: Overlock sewing machine

- Brand: Juki

- Origin: Nihon

|

| Fig: Over lock sewing machine. |

Measurement of Dimensional stability:

Dimensional stability: This is the exam past times which dimensional stability of cloth (i.e.: shrinkage & spirality) are measured. For this test, cloth has to live washed per attention label code.

Test specimen & Equipment:

- Sample size: exterior = (50x50) cm as well as Inside = (35x35) cm

- Method: ISO 6330: 2001 2A/5A

- Equipment used: washing machine (Rota wash)

- Washing at 400C X 41’, As per attention label code.

- Conditioning: Put the sample inwards tabular array for iv hrs for conditioning earlier starting test.

- Cut the sample 50x50 cm & benchmark should live 35x35 cm.

- Stitch the sample (3 sides) past times over lock sewing machine.

- Put sample inwards washing machine as well as run according to buyer’s choice.

31.5 + 31 + 30.8

After test: Inside measurement= ........................... = 31.1cm

3

Before launder - After wash

Before launder - After wash

Shrinkage = ........................................... X 100%

Before wash

Before wash

35 - 31.5

= ................ X 100 =11.14 %

35

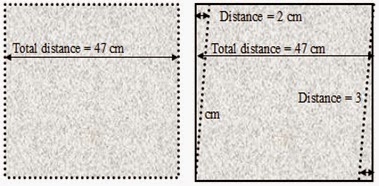

Spirality Calculation:

Total distance = 47 cm.

Average spiral distance = (2+3)/2 = 2.5 cm

35

|

| Figure: Measuring template |

|

| Figure: Spirality mensuration dimension |

Average spiral distance = (2+3)/2 = 2.5 cm

Average spiral distance

Spirality = ..................................... x 100% = (2.5×100)/47 = 5.32 %

Total distance

Conclusion:

Conclusion:

The dyeing lab machineries are varied from manufacturing flora to factory. The Devine Fabrics dyeing lab is good equipped alongside dissimilar machineries along alongside necessary chemicals past times which diverse types of lab dip tin live developed as well as a set out of tests are done inwards the physical lab alongside assured quality. All the equipments are sufficiently plenty to encounter the buyer requirements successfully. But all the tests cannot live conducted here.

You tin too like:

- Types of Dyeing Machine

- Study on Different Laboratory Equipments of a Modern Dye House

- Study on the Garments Washing as well as Dyeing Machine

- Hydro Extractor | Advantages of Hydro Extractor inwards Textile Finishing Process

- Working Principle of HTHP Beaker Dyeing Machine

- Working Process of Skein Dyeing Machine

- Working Process of Winch Dyeing Machines

- Specification of Printing Machineries

- Working Process of Jigger Dyeing Machine

- Working Procdure of Roller Printing

- List of Dyeing Machineries/Printing Machineries/Finishing Machineries

- Working Process of Package Dyeing Machine

- Working Process of Roller Hank Dyeing Machines

- Soft Flow Dyeing Machine as well as Principle of Soft Flow Dyeing Machine