Yaa Latest Dry Out Washing Techniques Inwards Denim Garments (Part-3)

Monday, 17 December 2018

Edit

Latest Dry Washing Techniques inward Denim Garments (Part-3)

Asma Akhi

&

Md.Hasibur Rahman Sunny

Dept. of Textile Engineering

Bangladesh University of Business & Technology

&

Md.Hasibur Rahman Sunny

Dept. of Textile Engineering

Bangladesh University of Business & Technology

Previous Post

CHAPTER-03

Raw Materials & Methodology

Raw Materials & Methodology

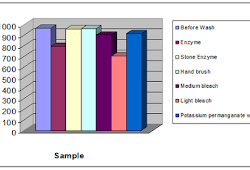

The methodology of this projection run was experimental. To perform a successfully experiment, the next materials, chemical, musical instrument too methods were used inward our projection work.

Material:

- Denim Fabric (70% Cotton 20% Poly 10% Rayon)

- Emery Paper (320)

- Potassium Permanganate(KMnO4)

- Resin

- Neutral Agent(Meta BSF)

- Desizing Agent

- Enzyme Agent

- Sodium Carbonate/Soda Ash

- Bleaching Powder

- Softener

- Paradise Washing Plant Ltd.

- Testing laboratory inward People's Republic of Bangladesh University of Business & Technology

- Wet Processing Laboratory inward People's Republic of Bangladesh University of Business too Technology (BUBT)

- Destroy Machine

- Pressing Crinkle Machine

- Iron Machine (For Crinkle)

- Tagging Machine

- Spray Gan Machine (For PP Spray)

- Sample Washing Machine

- Hydro-extractor

- Dryer Machine

For Hand Scraping/Hand Brush:

Material: Emery newspaper

Instrument: Rubber Balloon/Dummy etc.

Method:

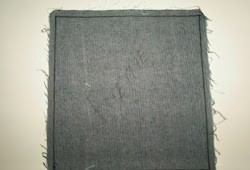

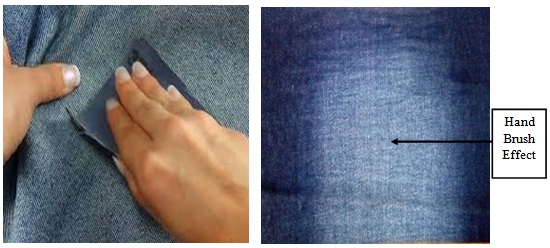

Hand brush amongst paper, commonly known every bit scrapping is the most widely used physical care for for creating the blasting effect. It is normally done past times mounting the garment on prophylactic balloons. After mounting the garment air balloon is filled amongst air to expose the surface area to operate. It is of import to fill upwards the pressure.

Hand sand is the pace which is mostly beingness done inward stiff cast of garments to larn the distressed look. Locations tin live forepart thigh & dorsum spot or it tin live overall / global application every bit per the Standard. Emery newspaper is beingness used to scrape the garments inward item placement & design. Emery newspaper comes inward dissimilar number mostly outset from xl till 600 too above, higher the number finer the emery paper, lower the coarseness of the paper. In the garment manufacture from 220, 320 & 400 number papers are most pop & widely used. Purpose of doing this physical care for is brand used worn out hold off to the garments.

Most mutual used degree no of emery newspaper is 320.Then sent for farther processing. Hand rubbing is done on specific surface area of garments past times emery newspaper according to approve sample. One garment must live done past times i operator solely to get got residuum intensity on both the leg.

|

| Fig 03: Hand Brush Sample |

Material: Emery Paper, Stone Tools

Instrument: Destroy Machine, Hacksaw Blade, Knife, Needle etc.

Method:

Destroy is newly fashion on garments. One of the most pop sorry effects currently, ‘Destruction’ is an fine art which brand denim hold off unique & used. It tin also live achieved past times cutting it thru knife the warp yarns & hold the weft yarn every bit is to demo white thread. Holes also tin live made past times cutting weft & warp yarns. These are all manual processes & every garment volition hold off unique & dissimilar than others.

- We tin brand holes inward jeans past times overdoing dissimilar methods. The fob is to brand the holes hold off natural. Grind away at the stuff slowly. Try non to localize the worn area, spread it amongst diminishing wearable the farther nosotros larn from the intended hole.

- The surface area to a greater extent than or less the hole should live worn out every bit good every bit bleached to farther blend the hole amongst the surrounding fabric. "Finish" the edges amongst a pumice rock or sandpaper dampened inward bleach. Also dampening a sponge amongst bleach too applying it to the outer edges of the hole volition add together to the natural worn look.

- It is of import that what types of hold off nosotros desire to meet on our denim. It is recommended using a abrupt bag knife/blade. Be careful, they are really sharp. Rub the blade of the knife/blade perpendicular to the trace of piece of job of the rip that nosotros want.

- To reinforce this newly created hole, plough your pants within out too house an adequately cutting slice of stuff to a greater extent than or less it too sew together it. An Fe on volition run every bit well, but the stitching, done either past times manus or amongst a sewing machine, volition larn far hold off much better.

- It is preferred that non likewise many holes, iii to 5 should live enough. The electrical flow trend, however, seems to live for smaller holes.

|

| Fig 04: Destroy Machine |

|

| Fig 05: Destroying sample By Machine |

|

| Fig 06: Destroying sample By Knife |

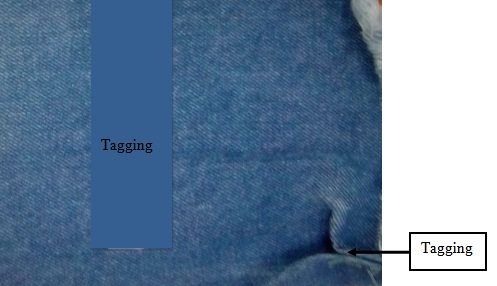

Material: Plastic or Nylon Tag Pins

Instrument: Tagging Machine

Method:

Tacking or to a greater extent than commonly tag pinning is a really inward fashion agency inward denim garment inward these days. In this physical care for the outcome is created past times swift tag machines amongst the aid of plastic or nylon tag pins inward stiff cast of garment to larn contrast.

Usually tag pivot machines are used to attach tag pins to garment. The physical care for is really uncomplicated too proceeds as; garment is folded on required surface area too tacked through folds. Number of folds tin live ii to 4 or v inward regular inward tacking. These tag guns are non particularly designed for heavy folds similar nosotros exercise inward tacking thus durability of the gun is a consistent problem. Also broken needles of tag gun are number for both operator too consumer. Automated tacking machines are used to a greater extent than successfully inward some units. These machines are chip expensive but are far to a greater extent than efficient too secure than tag guns.

|

| Fig 07: Tagging Sample |

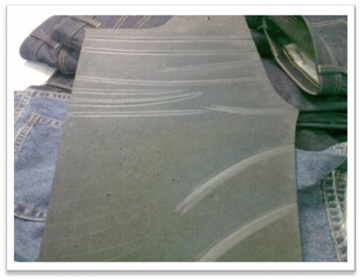

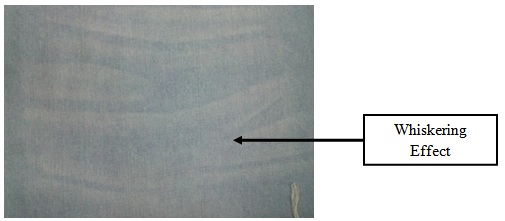

Material: Sand Paper

Instrument: Cutter Knife, Pattern Board, Rubber balloon etc

Method:

Various methods are designed to exercise this impression on jeans. Such as:-

Related:

Sometimes split patterns are made too fixed on balloons to brand mustaches. These patterns are made of sparse prophylactic sheets too electrical wires or prophylactic cords too pasted on balloons for pattern lines. Thin trace of piece of job patterns are really piece of cake to run inward that agency but it is non much successful for broad lines.

Engraved patterns on thick board similar difficult prophylactic sheets are widely used for whiskers impression making. This take in is really uncomplicated to depict lines on prophylactic sheets too engrave them amongst blade. Garment is places on canvas too scrapped on specific surface area to depict this impression on garment. For its depression terms patterns, it is most often used inward modest industries particularly where the production is non consistent to style.

|

| Fig 08: Whiskering pattern made followed past times a Style |

|

| Fig 09: Making whiskering outcome on the torso |

|

| Fig 10: Whiskering Sample |

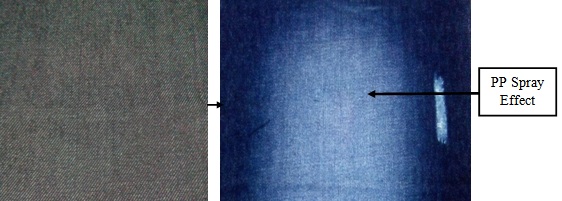

Chemical: KMnO4

Material: Emery Paper

Instrument: P.P Spray Gun, Rubber Balloon etc

Method:

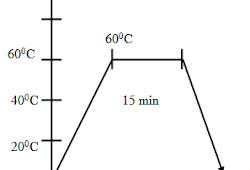

Potassium permanganate spray is done on jeans to get got a vivid outcome on sand boom area. One of import affair nigh the potassium permanganate (KMnO4) spray is, this is normally a sporting physical care for to increase the outcome of sand blast. Potassium permanganate solution is sprayed on the blasted surface area of jeans garment amongst the aid of a normal spray gun & this solution is made past times potassium permanganate & water, Sometimes CH3COOH (Acetic Acid) is used for solution preparation. Garments are mounted on balloons too filled amongst air to larn impressions of PP spray. Garment is scrubbed over pattern carefully. This performance requires high skilled labor too who tin handgrip uniformity.

This potassium permanganate spray appears pinkish on the garment when fresh too turns to dingy chocolate-brown on drying. The garment is hanged inward opened upwards to dry out afterwards potassium permanganate spray too when the potassium permanganate turns its colors completely too then it is considered to ready for the side past times side process. Doing afterwards enzyme or bleach bike volition give to a greater extent than natural & white outcome that doing inward rigid.

It is ever followed past times neutralization process. Sodium Meta bi-sulphate is most commonly used neutralizer. Influenza A virus subtype H5N1 number of products are available inward the marketplace position for the neutralization physical care for similar sodium meta bi-sulphate selected on the bases of outcome required on blasted area.

|

| Fig 11: Raw Sample Fig 12: PP Sample |

Next business office volition give away soon.....