Yaa High Functioning Polyethylene Fiber - An Overview

Monday, 17 December 2018

Edit

High Performance Polyethylene Fiber - An Overview

Muhammad Imteaz Anjum

School of Textile as well as Design

University of Management as well as Technology Lahore, Islamic Republic of Pakistan

Email: imteaz.anjum@gmail.com

Cell: +92332-2424424

School of Textile as well as Design

University of Management as well as Technology Lahore, Islamic Republic of Pakistan

Email: imteaz.anjum@gmail.com

Cell: +92332-2424424

Introduction

Gel-spun polyethylene fibres are ultra-strong, high-modulus fibres that are based on the uncomplicated as well as flexible polyethylene molecule. They are called high-performance polyethylene (HPPE) fibres, high-modulus polyethylene (HMPE) fibres or sometimes extended chain polyethylene (ECPE) fibres. The gel-spinning procedure uses physical processes to brand available the high potential mechanical properties of the molecule. This has been quite successful but at that spot is nonetheless ample room for improvement.

|

| Polyethylene fiber |

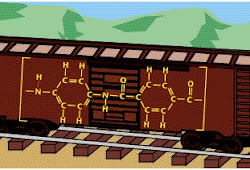

The polyethylene is a long chain aliphatic hydrocarbon as well as it is thermoplastic. The Tg is around -120ºC. Tm depends upon the construction which ranges from 108-132ºC. It has high molecular weight methyl hydride series as well as has a adept resistance to chemic attack. Because it is a crystalline stuff as well as does non interact amongst whatever liquids, at that spot is no solvent at room temperature.

|

| Basic construction of polyethylene |

Gel-spun high-performance polyethylene fibres are produced from polyethylene amongst a really high molecular weight (UHMW-PE). This stuff is chemically identical to normal high-density polyethylene (HDPE), but the molecular weight is higher than the ordinarily used PE grades. It is inward the attain that is used inward abrasion-resistant technology scientific discipline plastics. Different from all other high-performance fibres, the molecules inward high functioning polyethylene fibres are non ‘preformed’ to shape high tenacity as well as modulus fibres. In aramids as well as comparable fibres, the molecules tend to shape rod-like structures as well as these take exclusively live oriented inward 1 direction to shape a strong fibre. Polyethylene has much longer as well as flexible molecules as well as exclusively yesteryear physical treatments tin give notice the molecules live forced to assume the straight (extended) conformation as well as orientation inward the direction of the fibre. All the physical as well as chemic properties of polyethylene rest inward the fibres. The differences upshot from the high chain extension (stretching), the high orientation as well as the high crystallinity. The gel-spun fibres accept properties that are superior to those made yesteryear solid-state processes.

Gel Spinning

High functioning polyethylene fibres are commercially produced nether the merchandise names Dyneemaby DSM High Performance Fibers inward the Netherlands as well as yesteryear the Toyobo/DSM articulation firm inward Japan, as well as Spectra yesteryear Honeywell (formerly Allied Signal or Allied Fibers) inward the USA. The basic theory almost what a super-strong polyethylene fibre should expect similar was already available inward the 1930s from the ideas of Carothers, but it took almost one-half a century to create HPPE fibres.1 The basic theory of how to create a super-strong fibre from a polymer such as polyethylene is slow to understand. In normal polyethylene the molecules are non orientated as well as are easily torn apart. To brand strong fibres, the molecular chains must live stretched, oriented as well as crystallised inward the direction of the fibre. Furthermore, the molecular chains must live long to accept sufficient interaction as well as for this argue polyethylene amongst an ultra-high molecular weight (UHMW-PE) is used as the starting material. Usually extension as well as orientation are realised yesteryear drawing. The job is that spinning these fibres from the melt is almost impossible due to the extremely high melt viscosity. Furthermore, the drawing of a melt processed UHMW-PE is exclusively possible to a really express extent owing to the really high marking of entanglement of the molecular chains. In the gel spinning procedure these ii problems are solved:the molecules are dissolved inward a solvent as well as spun through a spinneret. In the solution the molecules move disentangled as well as rest inward that Blue Planet afterwards the solution is spun as well as cooled to give filaments. Because of its depression marking of entanglement, the gel spun stuff tin give notice live drawn to a really high extent. The primary steps inward the procedure are the continuous extrusion of a solution of ultra high-molecular weight polyethylene (UHMW-PE) Spinning of the solution, gelation as well as crystallization of the UHMW-PE. This tin give notice live done either yesteryear cooling as well as extraction or yesteryear evaporation of the solvent. Super drawing as well as removal of the remaining solvent gives the fibre its final properties but the other steps are essential inward the production of a fibre amongst adept characteristics. In the gel-spinning process, non exclusively exercise all the starting parameters accept an influence on the final properties of the fibre, the dissimilar procedure steps also influence all the next stages inward the production of the fibre. So, starting from the same principles, Dyneema as well as Spectra may job really dissimilar equipment to create comparable fibres.

Spinning Solution

With long-chain, flexible polymers the high orientation required tin give notice live obtained yesteryear drawing upwards to a really high describe ratio (50–100 times). Melt processed UHMW-PE tin give notice live drawn upwards to five times only, as the interaction betwixt the molecular chains is also high because of the molecular entanglements. In solution, the molecules disentangle but at that spot rest a issue of cross-overs determined yesteryear the concentration as well as the length of the molecules. The flexible molecules assume a roughly spherical shape amongst a diameter proportional to the cubic source of the molecular weight. For the UHMW-PE chains the diameter of such a ball is almost 1% of the full chain length. As presently as strain is applied when the solution is pressed through the spinneret, the molecules are forced into to a greater extent than elongated shape For maximum fibre strength, the polyethylene molecules should live as long as possible. From an economical indicate of thought the concentration of the solution should live as high as possible. However, these ii factors together upshot inward a solution that has a viscosity that is far also high to spin. Careful optimisation of these parameters is an essential move of the process.

Gelation as well as crystallization

The solvent used inward the polyethylene gel-spinning procedure should live a adept solvent at high temperatures (>100°C) but at lower temperatures (<80°C) the polymer should easily crystallize from the solution. After the spinneret, the solution is cooled inward the quench, the solvent is removed as well as a gel fibre is formed. This tin give notice live done yesteryear evaporation or yesteryear extraction of the solvent.

Drawing

The final properties of the fibre inward the gel-spinning procedure are achieved inward the super drawing stage. All the preceding steps are needed to brand this possible. The strength as well as modulus are straight related to the describe ratio. The maximum attainable describe ratio appears to live related to the molecular weight as well as the concentration. The attainable describe ratio increases amongst decreasing concentration, but for each molecular weight at that spot is a minimum concentration below which drawing is non possible, due to insufficient molecular overlap.

Properties

A. Tensile properties: The primary properties of the Dyneemaand Spectra fibres are high strength as well as high modulus inward combination amongst the depression density. HPPE fibres accept a density slightly less than one, then the fibre floats on water. Whereas the strength as well as modulus are already really high. The tenacity is 10 to xv times that of adept character steel as well as the modulus is instant exclusively to that of special carbon. Elongation at suspension is relatively low, as for other high-performance fibres, but owing to the high tenacity, the unloosen energy to suspension is high.

B. Energy absorption: Dyneema as well as Spectra fibres tin give notice absorb extremely high amounts of energy. This belongings is utilized inward products for ballistic protection. But it makes the fibre as suited for products such as cut-resistant gloves as well as motor helmets. The fibres tin give notice also live used to ameliorate the comport upon strength of carbon or drinking glass fibre-based composites. In these applications, non exclusively the high tenacity is used but also the high unloosen energy absorption.

Related:

C. Fatigue Fatigue: is really of import in, for example, rope applications. HPPE fibres are the first high-performance fibres that non exclusively accept a high tenacity but that also accept tension as well as bending fatigue properties comparable amongst the ordinarily used polyamide as well as polyester grades inward ropes.

D. Abrasion resistance: Abrasion resistance is really of import inward ropes, also inward gloves. In many of applications it is at to the lowest degree 1 of the factors that determines have on as well as tear as well as then the service life. The high molecular weight polyethylene used for HPPE fibres is also a well-known technology scientific discipline plastic.

E. Effects of water: Polyethylene is non hygroscopic as well as does non absorb water.The fibres accept a really depression porosity, thence H2O absorption inward the fibre is negligible.

F. Chemical resistance: HPPE fibres are produced from polyethylene as well as exercise non comprise whatever aromatic rings or whatever amide,hydroxylic or other chemic groups that are susceptible to assail yesteryear aggressive agents.The upshot is that polyethylene as well as peculiarly highly crystalline, high molecular weight polyethylene is really resistant against chemicals.

Applications of polyethylene fibres:

- Medical implants

- Cable as well as marine ropes

- Sail stuff

- Composites similar Pressure vessel boat hulls, sports equipment, comport upon shields

- Fish netting

- Concrete reinforcement

- Protective clothing

- Can live used inward radar protective encompass because of its depression dielectric constant

- Can live used as a lining stuff of a pond which collects evaporation of H2O as well as containment from industrial plants.

- (2012). Retrieved 2015, from https://en.wikipedia.or: https://en.wikipedia.org/wiki/Ultra-high-molecular-weight_polyethylene

- (2013). Retrieved 2015, from textilelearner.blogspot.com: /search?q=polyethylene-fiber-properties-of

- Hearle, J. W. (2001). High Performance Fibers. cambirige england: woodhead publishing express .

- (2001). Retrieved 2015, from http://nptel.ac.in/: http://nptel.ac.in/courses/116102026/synthetic%20fibers-m7/polyethylene.htm