Now You Know Aramid Fibers - An Overview

Tuesday, 22 January 2019

Edit

Aramid Fibers-An Overview

Muhammad Imteaz Anjum

School Of Textile And Design

University Of Management And Technology Lahore, Pakistan

Email:- anjum5270@gmail.com

Cell: +92332-2424424

School Of Textile And Design

University Of Management And Technology Lahore, Pakistan

Email:- anjum5270@gmail.com

Cell: +92332-2424424

Introduction

All fibers used in polymer engineering composites can be divided into two categories, namely synthetic fibers and natural fibers. Synthetic fibers are the most common. Although there are many types of synthetic fibers, glass, carbon and aramid fibers represent the most important.Kevlar is an aromatic polyamide or aramid fiber introduced in early 1970s by DuPont. It was the first organic fiber with sufficient tensile strength and modulus to be used in advanced composites. It has approximately five times the tensile strength of steel with a corresponding tensile modulus. Originally developed as a replacement for steel in radial tires, aramid is now used in a wide range of applications. It is a trade name of aramid fiber. (vigotsky, 2002)

Definition

The U.S. Federal Trade Commission gives a good definition of an aramid fiber as "a manufactured fiber in which the fiber forming substance is a long chain synthetic polyamide in which at least 85% of the amide linkages are attached directly to two aromatic rings. (comparison of aramid fibers, 2003)

History

First time aramid fibers commercially introduced by an American company DuPont in 1960 with trade name of Nomex. These Nomex fibers was well known due to their good thermal and electrical insulations properties. In 1971 DuPont introduced a much higher tenacity and modules fiber with trade name of Kevlar. Scientists in the fields of liquid crystals, polymers, rheology and fibre processing, as well as process and system engineers, spent several years prior and during the early stage of its market introduction establishing the basics and fundamental understanding necessary to take full advantage of this new class of high-performance materials. (Hearle, 2001)

Basic Structure and chemical composition of aramid fibers

Tho monomers of aramid fibers are consist of 1,4-phenyl-diamine (para-phenylenediamine) and terephthaloyl chloride. The result is polymeric aromatic amide with altering benzene ring and amide groups. When they produced these polymer strand aligned randomly. Technically, aramid fibers are long-chain synthetic polyamides. Aramid fibers have extremely high tensile strength, which is why they are commonly used in armor and ballistic protection applications. With a distinctive yellow color, aramid fibers are frequently used in advanced composite products which require high-strength and light-weight properties. The chemical composition of aramid is poly para-phenyleneterephthalamide (PPD-T) and it is more properly known as a para-aramid. It is oriented para-substituted aromatic units. Aramids belong to the family of nylons. Common nylons, such as nylon 6,6 do not have very good structural properties, so the para-aramid distinction is important. Aramid fibers like Nomex or Kevlar, however, are ring compounds based on the structure of benzene as opposed to linear compounds used to make nylon. The aramid ring gives thermal aramid stability, while the para structure gives it high strength and modulus. Like nylons, aramid filaments are made by extruding the precursor through a spinneret. The rod form of the para-aramid molecules and the extrusion process make Kevlar fibers anisotropic--they are stronger and stiffer in the axial direction than in the transverse direction. In comparison, graphite fibers are also anisotropic, but glass fibers are isotropic.

|

| Figure1: Chemical composition of Kevlar |

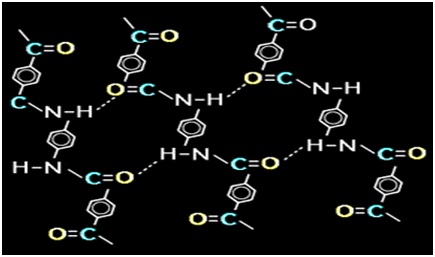

When PPD-T solutions are extruded through a spinneret and drawn through an air gap during fiber manufacture, the liquid crystalline domains can orient and align in the flow direction. Kevlar can acquire a high degree of alignment of long, straight polymer chains parallel to the fiber axis. The structure exhibits anisotropic properties, with higher strength and modulus in the fiber longitudinal direction than in the axial direction. The extruded material also possesses a febrile structure. This structure results in poor shear and compression properties for aramid composites. Hydrogen bonds form between the polar amide groups on adjacent chains and they hold the individual Kevlar polymer chains together [8]. It is shown as in the following figure:

|

| Figure 2: Hydrogen bonds form between the polar amide groups (A history of body armour-bullet proof vasts, 1993) |

There are two main types of aramid fibers.

- Meta- aramid

- Para- aramid

1. Meta-aramid

Fibers made from the meta aramid have the excellent thermal, chemical and radiation resistance and are make the fire retardant textiles such as outer wear for fire fighters and racing car drivers. Nomex and teijiconex are examples of meta aramids.

2. Para-aramids

Fibers which are made from the para-aramid have higher strength. These are more commonly used in fibers reinforcement plactics for civil engineering structures, Stress skin panels, and other highly tensile strength applications. Kevlar and technora are example of para-aramid fibers. (Hearle, 2001) (Properties of Aramid Fibers, 2015)

Different trade name of aramid fibers

Aramid fibers are available with different trade names. There properties are determine by the manufacturing process, conditions in which fibers are prepared and end uses. Different trade names of aramid fibers are Kevlar, Technora, Tawron, Nomex etc. (Aramid Fibers, trade names)

Manufacturing Process of aramid fibers

The polymer poly-metaphenylene isophthalamide is used to make meta- aramids and the polymer p-phenylene terephthalamide to make para-aramids. Because the aramids decompose before they melt they are produced by wet and dry spinning methods. Sulphuric acid is the normal solvent used in the spinning processes. In wet spinning a strong solution of the polymer, which also contains inorganic salts, is spun through a spinneret into weak acid or water. In this bath the salts leach out. In the dry spinning process the salts are more difficult to remove and this process is only used to produce the weaker meta-aramid fibres. In both processes post treatment of the fibres by additional drawing is used to optimise fibre properties. Aramid products are available as filament yarn, staple fibre or pulp. (Aramid fibers manufacturing method)

|

| (Man-made Fibres, 2015) |

Fiber Structure

In aramid fibers a series of synthetic polymers in which repeating units have large phenyl rings are linked together by amide groups. Amide groups (CO-NH) form strong bonds that are resistant to solvets and heat. Phenyl rings are bulky six-sided groups of carbon and hydrogen atoms that prevent polymer chains from rotating and twisting around their chemical bonds.

Fiber Properties

Aramid fibers have medium to ultra-high strength, medium to low elongation and moderately high to ultra-high modulus with the densities ranging from 1.38g/cm3. Heat-resistant and flame-retardant fibers contain high proportion or meta-oriented phenylene rings, whereas ultra-high strength high-modulus fibers contain mainly para-oriented phenylene rings.

Chemical Properties

All aramids contain amide links that are hydrophilic. However, not all aramid products absorb the same moisture. The PPD-T (poly-phenylene terephathalamide) fiber has very good resistance to many organic solvents and salt, but strong acids can cause substantial loss of strength. Aramid fibers are difficult to dye due to their high Tg. Also, the aromatic nature of para-aramid is responsible for oxidative reactions when exposed to UV light, that leads to a change in color and loss of some strength.

Themal Properties

Aramid fibers do not melt inn the conbentional sense but decompose simultaneously. They burn only with difficulty because of limited oxygen Index values. It should be mentioned that at 300 degrees celcius some aramid types can still retain about 50% of their strength. Aramid fibers show high crystallinity which results in negligible shrinkage at high temperature.

Mechanical Properties

Aramid yarn have breaking tenacity of 3045 MPa, in other words more than 5 times than this steel (under water, aramid is 4 times stronger) and twice than this of glass fiber or nylon. High strength is result of its aromatic and amide group and high crystallinity. Aramid retains strength and modulus at temperatures as high as 300 degrees celcius. It behaves elastically under tension. When it comes to severe bending, it shows non-linear plastic deformation. With tension fatigue, no failure is observed even at impressively high loads and cycle times. Creep strain for aramid is only 0.3%.

To sum up, aramid general characteristics are:

- v High strength

- v Resistance to absorption

- v Resistance to organic solvent

- v Good chemical resistance

- v No conductivity

- v No melting point low flammability

- v Excellent heat, and cut resistane

- v Sensitive to acids and ultraviolet radiation (ARAMID FIBER CHARACTERISTICS, 2015)

Aramid main advantages are high strength and low weight. Like graphite, it has slightly negative axial coefficient of thermal expansion, which means aramid laminates can be made thermally table in dimensions. Unlike graphite, it is very resistant to impact and abrasion damage. It can be made waterproof when combined with other materials like epoxy. It can be used as a composite with rubber retaining its flexibility. High tensile modulus and low breakage elongation combined with very good resistance to chemicals make it the right choice for different composite structural parts inn various applications.

Disadvantages of aramid fibers

On the other hand, aramid fiber has a few disadvantages. The fibers assorb moisture, so aramid composites are more sensitive to the environment than glass or graphite composites. For this reason, it must be combined with moisture resistance materials like epoxy systems. Compressive properties are ralativly poor too. Consequently, aramid fiber is not used in bridge building or whenever this king of resistance in needed. Also, aramid fibers are difficult to cut and to grind without special equipments ( e.g special scissors for cutting, special drill bits). Finally, aramid suffer some corrosion and are degradated by UV light. For this reason they must be properly coated. (ADVANTAGES - DISADVANTAGES, 2015)

Key Applications of Aramid Fibre

- Some applications for aramid fibres are listed below. It is usually used as fibre reinforcement for polymer matrix composites.

- Ballistic protective applications such as bullet proof vests

- Protective apparel such as gloves, motorcycle protective clothing and hunting gaitors, chaps and pants.

- Sails for sailboats, yachts etc

- Belts and hosing for industrial and automotive applications

- Aircraft body parts

- Boat hulls

- Fibre optic and electromechanical cables

- Friction linings such as clutch plates and brake pads

- Gaskets for high temperature and pressure applications

- Adhesives and sealants (Aramid Fibre ( Kevlar / Twaron ) – Properties and Applications, 2015)

Comparison of aramid fiber with other high performance fibers

*** Aramid fibers have High Strength to Weight Ratio

Force per unit area at failure / Density = is the Strength to Weight ratio of this material. Kevlar is very strong and is slightly stronger than Carbon Fiber per unit weight.

| MATERIAL | Strength to weight KN.m/kg. | Ultimate Strength MPa | Density g/cm3 |

| Spectra fiber (UHMWPE) | 3619 | 2300-3500 | .97 |

| Kevlar (ARAMID) | 2514 | 2757 | 1.44 |

| Carbon Fibre | 2457 | 4137 | 1.75 |

| Carbon laminate | 785 | 1600 | 1.5 |

| E Glass Fibre | 1307 | 3450 | 2.57 |

| E Glass laminate | 775 | 1500 | 1.97 |

| Polypropylene | 89 | 19.7-80 | .91 |

| S Glass Fibre | 1906 | 4710 | 2.47 |

| Spider Silk | 1069 | 1000 | 1.3 |

| Balsa axial load | 521 | 83 | .16 |

| Steel alloy ASTM A36 | 254 | 400 | 7.8 |

| Aluminium alloy | 222 | 248-483 | 2.63-2.8 |

| Oak | 87 | 65 | .75 |

| Epoxy | 26 | 12-30 | 1.23 |

| Nylon | 69 | 75 | 1.15 |

*** Kevlar (ARAMID) is Much Stiffer than Glass but Not as Stiff as Carbon Fiber.

The Rigidity of a material is measured by its Youngs' Modulus.

Kevlar is quite stiff and has low stretching at break.

The Rigidity of a material is measured by its Youngs' Modulus.

Kevlar is quite stiff and has low stretching at break.

| Material | Young's Modulus GPa |

| PTFE (Teflon) | 0.5 |

| Rubber (small strain) | 0.01-0.1 |

| PTFE (Teflon) | 0.5 |

| Low density polyethylene | 0.2 |

| UHMWPE (such as Dyneena or Spectra) | .7 |

| Polypropylene | 1.5-2 |

| Nylon | 2-4 |

| Pine wood (along grain) | 8.963 |

| Oak wood (along grain) | 11 |

| Aluminium | 69 |

| Aramid (such as Kevlar and Twaron) | 70.5-112.4 |

| Brass and bronze | 100-125 |

| Glass-reinforced plastic (70/30 by weight fibre/matrix, unidirectional, along grain) | 40-45 |

| Carbon fiber (depends on direction and type) | 300-400 |

| Carbon fiber reinforced plastic (70/30 fibre/matrix, unidirectional, along grain) | 181 |

| Steel | 200 |

| Single-walled carbon nanotube | 1,000+ |

*** Tensile Strength of Kevlar is lower than E Glass

This table is offered as a comparison only since there are a great number of variables.

(Aramid fibers, 2015)

Conclusion

The current production of continuous aramid fibres (both low and high modulus) worldwide is estimated at about 60,000 metric tons (MT)/year, only 4% of which goes into composite applications. This represents 2,400 MT/year, compared to 40,000 MT/year of carbon and five million MT/year of glass fibre.

The development of para-aramid fibres (especially high-modulus) has been slowed down by certain disadvantages that have turned up gradually with their use. These disadvantages include poor compression strength, microcracking due to the high thermal expansion coefficient in the width direction, high moisture regain, and problems with processing (cutting, machining, finishing, surface aspect).

In addition, these fibres face stiff competition from carbon, which has much better mechanical properties and is available at lower cost. As a result, there is currently little to report in the way of major developments for composites applications.

References

This table is offered as a comparison only since there are a great number of variables.

| Material | MPa units |

| Carbon steel 1090 | 650 |

| High density polyethylene (HDPE) | 37 |

| Polypropylene | 19.7-80 |

| High density polyethylene | 37 |

| Stainless steel AISI 302 | 860 |

| Aluminium alloy 2014-T6 | 483 |

| Aluminium alloy 6063-T6 | 248 |

| E-Glass alone | 3450 |

| E-Glass in a laminate | 1500 |

| Carbon fiber alone | 4127 |

| Carbon fiber in a laminate | 1600 |

| Kevlar | 2757 |

| Pine wood (parallel to grain) | 40 |

Conclusion

The current production of continuous aramid fibres (both low and high modulus) worldwide is estimated at about 60,000 metric tons (MT)/year, only 4% of which goes into composite applications. This represents 2,400 MT/year, compared to 40,000 MT/year of carbon and five million MT/year of glass fibre.

The development of para-aramid fibres (especially high-modulus) has been slowed down by certain disadvantages that have turned up gradually with their use. These disadvantages include poor compression strength, microcracking due to the high thermal expansion coefficient in the width direction, high moisture regain, and problems with processing (cutting, machining, finishing, surface aspect).

In addition, these fibres face stiff competition from carbon, which has much better mechanical properties and is available at lower cost. As a result, there is currently little to report in the way of major developments for composites applications.

References

- A history of body armour-bullet proof vasts. (1993, august 25). Retrieved from www.inventore.about.com: www.inventores.about.com

- ADVANTAGES - DISADVANTAGES. (2015, november 15). Retrieved november sunday, 2015, from http://www.aramid.eu/: http://www.aramid.eu/advantages---disadvantages.html

- ARAMID FIBER CHARACTERISTICS. (2015, november 15). Retrieved november sunday, 2015, from http://www.aramid.eu/: http://www.aramid.eu/characteristics.html

- aramid fibers. (2015, 10 15). Retrieved 10 sunday, 2015, from http://www.christinedemerchant.com: http://www.christinedemerchant.com/aramid_characteristics.html

- aramid fibers manufacturing method. (n.d.). Retrieved from http://www.aramid.eu/: http://www.aramid.eu/manufacturing-methods.html

- Manufacturing Process of Aramid, /search?q=production-process-of-synthetic-fiber_9386

- Aramid Fibers, trade names. (n.d.). Retrieved from http://www.christinedemerchant.com/: http://www.christinedemerchant.com/aramid_characteristics.html

- Aramid Fibre ( Kevlar / Twaron ) – Properties and Applications. (2015, 10 15). Retrieved 10 sunday, 2015, from http://www.azom.com: http://www.azom.com/article.aspx?ArticleID=1384

- comparison of aramid fibers. (2003, october 13). Retrieved from carb.com: www.rarb.com " comparison of aramid fibers

- Hearle, J. W. (2001). High Performance Fibers. USA: Woodhead publishing limited.

- Man-made Fibres. (2015, 10 15). Retrieved 10 sunday, 2015, from http://www.cirfs.org/: http://www.cirfs.org/manmadefibres/fibrerange/Aramid.aspx

- Properties of Aramid Fibers. (2015, 10 15). Retrieved 10 sunday, 2015, from http://www.build-on-prince.com/: http://www.build-on-prince.com/aramid-fibers.html#sthash.RHkSA5Pn.YMwuoGQd.dpbs

- vigotsky, v. (2002). “ANTEC fundamentals forum will focus on innovative products and processes”, Plastics Engineering. new yark: brookfield center.