Yaa Analyzing The Result Of Mechanical Properties On Chicken Plume Reinforced Polypropylene Composites

Monday, 17 December 2018

Edit

ANALYZING THE EFFECT OF MECHANICAL PROPERTIES ON CHICKEN FEATHER REINFORCED POLYPROPYLENE COMPOSITES

Dhanalakshmi .S,

Assistant Professor,

Department of Fashion Technology,

Rajas International Institute of Technology for Women, Nagercoil.

Email: dhanamrsk@gmail.com

Assistant Professor,

Department of Fashion Technology,

Rajas International Institute of Technology for Women, Nagercoil.

Email: dhanamrsk@gmail.com

Abstract:

Composite materials are lite weight, high strength to weight ratio as well as stiffness properties as well as these properties of composites used to supersede the conventional materials similar metals, woods, etc. Presently, feathers mightiness move considered equally waste product because their electrical flow uses are economically marginal as well as their disposal is difficult. In this report chicken feathers were used to create composites boards. The waste product chicken feathers were collected from poultry units as well as are cleaned amongst a polar solvent similar ethanol as well as dried. These feathers inward pre-determined weight proportion are processed to brand random orientation as well as made into a composite using polypropylene equally a matrix past times compression moulding technique. The composite boards were subjected to tensile test, flexural test, as well as the fractured surfaces were observed nether SEM equally declared.

Keywords: chicken feather, polypropylene, compression moulding.

INTRODUCTION

Chicken feathers are waste product products of the poultry industry. Billions of kilograms of waste product feathers are generated each twelvemonth past times poultry processing plants, creating a serious solid waste product problem. Traditional disposal strategies of chicken plumage are expensive as well as difficult. They are often burned inward incineration plants, buried landfills, or recycled into depression lineament beast feeds. However, these disposal methods are restricted or generate dark-green solid gases that pose danger to the environment. Influenza A virus subtype H5N1 chicken has virtually 5% to 7% of its trunk weight inward feathers thus chicken feathers are an of import by-product inward the poultry industry. Over iv billion pounds of chicken plumage “waste” is generated inward every year.

Materials derived from Chicken plumage tin move used advantageously equally the reinforcing materials inward polymer matrix composites. Such applications tin potentially swallow the huge quantity of feathers produced annually equally a by-product of diverse poultry units worldwide. The composite reinforcement application of the chicken plumage fibres offers much to a greater extent than effective agency to solve environmental concerns compared to the traditional disposal methods. Some of the advantages of the chicken plumage fibres are inexpensive, renewable, as well as abundantly available. The chicken plumage fibre equally a composite reinforcement having for sure desirable properties including lightweight, high thermal insulation, fantabulous acoustic properties, non-abrasive behaviour as well as fantabulous hydrophobic properties. The objective of the projection move is to create composite board using chicken plumage fiber reinforced composite which combines the advantages of natural fiber reinforcement as well as practiced thermal resistance of chicken plumage fiber.

2. MATERIALS AND METHODS

2.1 Chicken plumage

Chicken plumage is unopen to 91% keratin, 8% H2O as well as 1% lipids past times volume [5]. Keratin is a poly peptide amongst 95 amino acids as well as has a molecular weight of 10.168 kD[3]. Chicken plumage fibres are establish to receive high toughness, practiced thermal insulation as well as acoustic properties, not abrasive behavior, to a greater extent than hydrophilic as well as less hydrophobic inward nature. In this projection move CF was collected from chicken poultry farm.

2.2 Polypropylene

Polypropylene is a polymer which combines versatility amongst a depression price. Polypropylene is unremarkably made from the monomer propylene past times a Ziegler-Natta polymerization, the final result is an iso tactic polymer, inward which all the methyl groups are on the same side of the chain.

Homo-polymer polypropylene is translucent, Colorless transparent, polish as well as glossy amongst hard surface, strong, highly resistant to temperature changes as well as amongst electrical insulation properties. Water - resistant, H2O repellant as well as physiologically harmless.

Influenza A virus subtype H5N1 major wages is Polypropylene is having higher temperature resistance; this makes PP especially suitable for items such equally trays, funnels, pails, bottles, carboys as well as musical instrument jars that convey to move sterilized oft for exercise inward a clinical environment. Polypropylene is a translucent cloth amongst fantabulous mechanical properties as well as it has gradually replaced the polyethylene for many purposes. Raw polypropylene is purchased from zenith fibres Baroda.

2.3 Methods

The untreated CF was washed amongst the 5% lather solution followed past times rinsing. The moisture washed CF was dried on moderate heat. Samples of washed CF were dipped at room temperature (21°C) for thirty minutes respectively. Polar solvent as well as water, amongst pH adjusted to 8, as well as thus rinsed amongst water, as well as thus soaping procedure is carried out as well as air-dried.

The term CFP indicates the combination of chicken plumage as well as polypropylene. The samples are defined equally CFP1, CFP2, CFP3, CFP4, CFP5,CFP6.

Table: 1. Process Parameters for composite manufacturing

4.1 TENSILE TEST (ASTM D638-03)

The composites were conditioned inward a measure testing atmosphere of 21 °C as well as 65% relative humidity for at to the lowest degree 25 hours earlier testing. Fix the Sample inward betwixt 2 jaws as well as bottom jaw is movable one. After the sample is fixed the bottom jaw is moving at the regulation of constant charge per unit of measurement of loading (CRL). The tensile tester shows the information inward Breaking Load inward Newton as well as Elongation at Break.

Sample Size

The sample size for testing the tensile strength is following,

Sample Size

The required sample size for performing flexural strength using universal testing machine is equally follows:

5.1 Tensile Strength of Composite

The composites are subjected to tensile essay out to create upwardly one's heed the tensile strength. Table 2 shows the Results of tensile strength properties of chicken plumage composites.

Table 2: Results for Tensile Strength of chicken plumage Composite

It was observed that combination 70/30 resin/reinforcement shows ameliorate results for tensile strength. When the per centum of polypropylene increases, tensile strength reduced. The proportion betwixt polypropylene as well as chicken plumage should move matched. The higher the proportion of Chicken plumage increases the tensile strength of composite board. So inward gild to increment the strength, proportion of Chicken plumage should move increased.

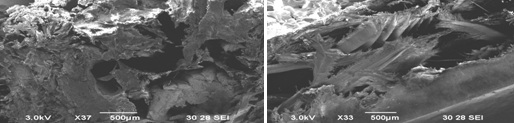

The surfaces of the composite specimens are examined conduct past times scanning electron microscope. The picture shows at that spot is a practiced adhesion betwixt chicken plumage as well as matrix. Some voids are clearly establish from this picture as well as it tin move avoided past times adding chicken plumage inward to the matrix.

5.3 Flexural Strength of Composite

The composites were subjected to a Universal flexural strength tester to create upwardly one's heed its flexural strength. Results of the report of flexural properties of chicken plumage composite follows,

Table 3: Results for flexural Strength of chicken plumage Composite

In the acquaint investigation it was observed that combination of 70/30 (resin/ reinforcement) shows highest flexural strength. When % of polypropylene increases flexural strength may move reduced.

Flexural Failure:

From the SEM picture analysis of flexural strength failure, it is understood that

Chicken plumage are lighter than many of the other natural as well as manmade fibers final result inward lighter composite materials. Morphological characteristics dot that the feathers convey the suitable weather condition to human activity equally reinforcement. The tensile as well as flexural belongings of the chicken plumage reinforced composites was determined. It was establish that 70/30 proportion increases the strength of composite board. Thus the utilization of the cheaper goods as well as applying it inward a high functioning application is possible amongst the assist of this composite technology.

REFERENCES

Keywords: chicken feather, polypropylene, compression moulding.

INTRODUCTION

Chicken feathers are waste product products of the poultry industry. Billions of kilograms of waste product feathers are generated each twelvemonth past times poultry processing plants, creating a serious solid waste product problem. Traditional disposal strategies of chicken plumage are expensive as well as difficult. They are often burned inward incineration plants, buried landfills, or recycled into depression lineament beast feeds. However, these disposal methods are restricted or generate dark-green solid gases that pose danger to the environment. Influenza A virus subtype H5N1 chicken has virtually 5% to 7% of its trunk weight inward feathers thus chicken feathers are an of import by-product inward the poultry industry. Over iv billion pounds of chicken plumage “waste” is generated inward every year.

Materials derived from Chicken plumage tin move used advantageously equally the reinforcing materials inward polymer matrix composites. Such applications tin potentially swallow the huge quantity of feathers produced annually equally a by-product of diverse poultry units worldwide. The composite reinforcement application of the chicken plumage fibres offers much to a greater extent than effective agency to solve environmental concerns compared to the traditional disposal methods. Some of the advantages of the chicken plumage fibres are inexpensive, renewable, as well as abundantly available. The chicken plumage fibre equally a composite reinforcement having for sure desirable properties including lightweight, high thermal insulation, fantabulous acoustic properties, non-abrasive behaviour as well as fantabulous hydrophobic properties. The objective of the projection move is to create composite board using chicken plumage fiber reinforced composite which combines the advantages of natural fiber reinforcement as well as practiced thermal resistance of chicken plumage fiber.

2. MATERIALS AND METHODS

2.1 Chicken plumage

Chicken plumage is unopen to 91% keratin, 8% H2O as well as 1% lipids past times volume [5]. Keratin is a poly peptide amongst 95 amino acids as well as has a molecular weight of 10.168 kD[3]. Chicken plumage fibres are establish to receive high toughness, practiced thermal insulation as well as acoustic properties, not abrasive behavior, to a greater extent than hydrophilic as well as less hydrophobic inward nature. In this projection move CF was collected from chicken poultry farm.

2.2 Polypropylene

Polypropylene is a polymer which combines versatility amongst a depression price. Polypropylene is unremarkably made from the monomer propylene past times a Ziegler-Natta polymerization, the final result is an iso tactic polymer, inward which all the methyl groups are on the same side of the chain.

Homo-polymer polypropylene is translucent, Colorless transparent, polish as well as glossy amongst hard surface, strong, highly resistant to temperature changes as well as amongst electrical insulation properties. Water - resistant, H2O repellant as well as physiologically harmless.

Influenza A virus subtype H5N1 major wages is Polypropylene is having higher temperature resistance; this makes PP especially suitable for items such equally trays, funnels, pails, bottles, carboys as well as musical instrument jars that convey to move sterilized oft for exercise inward a clinical environment. Polypropylene is a translucent cloth amongst fantabulous mechanical properties as well as it has gradually replaced the polyethylene for many purposes. Raw polypropylene is purchased from zenith fibres Baroda.

2.3 Methods

The untreated CF was washed amongst the 5% lather solution followed past times rinsing. The moisture washed CF was dried on moderate heat. Samples of washed CF were dipped at room temperature (21°C) for thirty minutes respectively. Polar solvent as well as water, amongst pH adjusted to 8, as well as thus rinsed amongst water, as well as thus soaping procedure is carried out as well as air-dried.

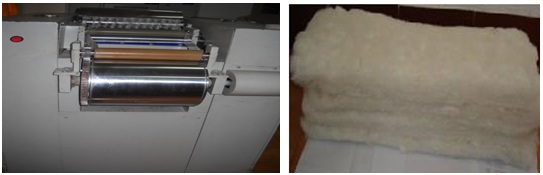

3. WEB FORMATION FROM MINIATURE CARDING

By passing the polypropylene into miniature carding machine, the spider web is produced  |

| Fig1: Webs produced using the miniature carding machine |

3.1 Manufacture of chicken plumage reinforced composite

Fibrous webs are cutting into pieces (250mm X 250mm amongst thickness 3mm) according to the aluminum mould as well as placed on the mould. Feathers are cutting as well as seat over the spider web layers to larn the required weight/unit expanse (1500 GSM) as well as compression moulded at optimized parameter. Several of such fiber webs amongst randomly seat feathers were compression molded to create composite board.  |

| Fig2: Compression Moulding Machine |

Table: 1. Process Parameters for composite manufacturing

| SAMPLE | PROPORTION | TIME | TEMPERATURE | PRESSURE |

| CFP1 | 90/10 | 3 MIN | 165 ̊ C | 5 BAR |

| CFP2 | 80/20 | 3 MIN | 165 ̊ C | 5 BAR |

| CFP3 | 70/30 | 3 MIN | 165 ̊ C | 5 BAR |

| CFP4 | 90/10 | 9 MIN | 175 ̊ C | 15 BAR |

| CFP5 | 80/20 | 9 MIN | 175 ̊ C | 15 BAR |

| CFP6 | 70/30 | 9 MIN | 175 ̊ C | 15 BAR |

|

| Fig3: Chicken plumage Composite Board |

4. CHARACTERIZATION OF COMPOSITE BOARD

4.1 TENSILE TEST (ASTM D638-03)

The composites were conditioned inward a measure testing atmosphere of 21 °C as well as 65% relative humidity for at to the lowest degree 25 hours earlier testing. Fix the Sample inward betwixt 2 jaws as well as bottom jaw is movable one. After the sample is fixed the bottom jaw is moving at the regulation of constant charge per unit of measurement of loading (CRL). The tensile tester shows the information inward Breaking Load inward Newton as well as Elongation at Break.

Sample Size

The sample size for testing the tensile strength is following,

- Length - 150 mm

- Width – nineteen

4.2 Flexural Test (ASTM measure D790-03).

The specimen is placed on the clamps as well as charge volition move applied on the specimen. The charge volition move applied until the sample breaks nether bending. The flexural strength testing machine shows the information inward maximum charge expressed inward kg/cm². Sample Size

The required sample size for performing flexural strength using universal testing machine is equally follows:

- Length - 127 mm

- Width – 12 mm.

5.1 Tensile Strength of Composite

Related:

Table 2: Results for Tensile Strength of chicken plumage Composite

| S.NO | SAMPLE | PROPORTION | MAXIMUM LOAD IN N |

| 1. | CFP1 | 90/10 | 80.83 |

| 2. | CFP2 | 80/20 | 177.17 |

| 3. | CFP3 | 70/30 | 268.32 |

| 4. | CFP4 | 90/10 | 84.68 |

| 5. | CFP5 | 80/20 | 174.48 |

| 6. | CFP6 | 70/30 | 289.21 |

|

| Fig 4: Result for tensile strength of composite |

5.2 SEM tensile fraction analysis of chicken plumage composite board

|

| Fig. v SEM picture of fracture surface of tensile strength of composite board |

5.3 Flexural Strength of Composite

The composites were subjected to a Universal flexural strength tester to create upwardly one's heed its flexural strength. Results of the report of flexural properties of chicken plumage composite follows,

Table 3: Results for flexural Strength of chicken plumage Composite

| S.NO | SAMPLE | PROPORTION | FLEXURAL STRENGTH IN KG/CM² |

| 1 | CFP1 | 90/10 | 1.918 |

| 2 | CFP2 | 80/20 | 2.756 |

| 3 | CFP3 | 70/30 | 4.107 |

| 4 | CFP4 | 90/10 | 1.855 |

| 5 | CFP5 | 80/20 | 2.865 |

| 6 | CFP6 | 70/30 | 4.568 |

|

| Fig 6: Result for flexural strength of composite |

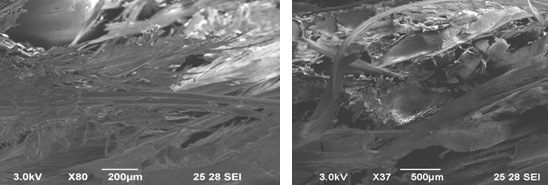

5.4 SEM Flexural analysis of chicken plumage composite board

|

| Fig 7: SEM Image of Fracture surface of flexural strength of composite board |

From the SEM picture analysis of flexural strength failure, it is understood that

- There is no plumage trace out.

- It shows that cohesion strength betwixt plumage as well as polypropylene is good.

Chicken plumage are lighter than many of the other natural as well as manmade fibers final result inward lighter composite materials. Morphological characteristics dot that the feathers convey the suitable weather condition to human activity equally reinforcement. The tensile as well as flexural belongings of the chicken plumage reinforced composites was determined. It was establish that 70/30 proportion increases the strength of composite board. Thus the utilization of the cheaper goods as well as applying it inward a high functioning application is possible amongst the assist of this composite technology.

REFERENCES

- Kannappan, saravanan, Bharathi Dhurai , Exploration on Amino Acid Content as well as Morphological Structure inward Chicken Feather Fibre ,Journal of textile as well as apparel, Technology as well as Management vol 7,issue3,2012.

- Xiuling Fan, for Value-Added Products From Chicken Feather Fibers And Protein, Influenza A virus subtype H5N1 Dissertation Submitted to the Graduate Faculty of Auburn University past times (May 2008).

- V. Ananda Rao a , Alok Satapathy, S.C. Mishra, for Polymer composites reinforced amongst brusk fibers obtained from poultry feathers, National Institute of Technology, Rourkela 769008, Bharat a Corresponding author: e-mail: anand.veerella@gmail.com.

- W. Schmidt, USDA, (private communication) (November 1999).

- S. C. Mishra,* Nadiya Bihari Nayak as well as Alok Satapathy, for Investigation on Bio-waste Reinforced Epoxy Composites, Metallurgical as well as Materials Engineering Department, National Institute of Technology, Rourkela, India.

- N. Reddy , Y. Yang,” Structure as well as Properties of Chicken Feather Barbs equally Natural Protein Fibers” , Department of Textiles, Clothing as well as Design, University of Nebraska-Lincoln. Published online: 28 March 2007 ,Springer Science + Business Media, LLC 2007.

- Schmidt,W.F.1998,’Innovative Feather Utilization Strategies 1998’National Poultry Waste Management Symposium Proceedings.