Yaa Latest Dry Out Washing Techniques Inwards Denim Garments (Part-1)

Monday, 17 December 2018

Edit

Latest Dry Washing Techniques inwards Denim Garments (Part-1)

Asma Akhi

Dept. of Textile Engineering

Bangladesh University of Business & Technology

Dept. of Textile Engineering

Bangladesh University of Business & Technology

Introduction

Denim garment (Jeans) washing or denim washing is 1 of the most widely used finishing treatments that conduct hold vast usage, due to its effects on appearance too comfort. Without washing, the denim garment is uncomfortable to wear, due to its weaving too dyeing effects. It essentially needs a finishing handling to larn inwards softer, to a greater extent than supple too polish which heighten wearer’s comfort.

Fashion is today incomplete without denim. Denim comes inwards all forms, looks too washes to stand upward for with every dress. Dry physical care for which is most pop for denim garments.

Bangladesh is a textile based country, Denim wearing clothing are existence produced with other wearing clothing to take in demand inwards the competitive marketplace of the world. Today’s are really fashion concern, It is really challenging to take in their quick modify of electrical flow demands. At nowadays the demand of denim wearing clothing with faded expect hence increasing rapidly. Various types of washing conduct hold been used on denim wearing clothing to give them used look. Common washing practices are Bleach wash, Enzyme wash, Garments/Normal wash, Bleach with Stone wash, Acid wash, Pigment launder etc. Among methods the Bleach launder & Enzyme launder is really widely used inwards the washing industry. Also used diverse types of dry out launder similar Hand brush, Grinding, Destroy, Whiskering, PP spray, Tagging, 3D etc.

The distressed jeans that nosotros take in some everywhere undergo a broad diversity of moisture equally good equally dry out treatments to larn the desired effects. Destroying denims is equally much an fine art equally it is a technique. The administration inwards fashion is varied across all areas peculiarly inwards denim dry out process, whether worn or torn to wrinkled or pressed; these trends tin appeal to a broad make of consumers. These tin live achieved past times diversity of denim dry out processing techniques which are mainly dependent on physical too on chemic abrasion of the surface dye at that topographic point past times producing dissimilar wash-down looks to the denim fabrics.

In a twill weave (used inwards denim), the stuff is constructed past times interlacing warp too filling yarns inwards a progressive alternation which creates a diagonal lawsuit on the face, or correct side, of the stuff too has a surface of diagonal parallel ridges. In some twill weave fabrics, the diagonal lawsuit may also live seen clearly on the dorsum side of the fabric. Due to the denim's right-hand twill construction, 1 color predominates on the stuff surface, Most of the Denim stuff construction is either 2/1 or 3/1 construction of either left or correct handed twill. Also because of this agency of weaving the threads to brand the fabric, the stuff is really strong too durable.

Over the years, many dissimilar denim stuff treatments conduct hold been introduced, including pre-washed, stone-washed, sand blasting, too dirty.

Purposes of Garments Washing:

- Washing physical care for of garment is done to create launder expect appearance. After washing the garments create a novel expect which seems the novel touching of fashion.

- By the washing technique, faded/old look, color or tinted touching is created inwards the garments which also seem the best touching of garments.

- It also create dissimilar outlook.

- Washing technique creates novel fashion such equally tagging, grinding, destroy, whiskering, permanent wrinkle, P.P spray, manus crapping, 3D etc. Which also seems the best touching of garments.

- The original too of import part of washing is to cut size materials equally a outcome the garment croak size gratuitous too croak soft manus feel.

- When these soft garments are touched hence it seems to best touching of garments.

- To attraction the customers/Buyer past times dissimilar types of Fashionable washing too marketplace developments.

CHAPTER-02

Literature Review

Literature Review

Hand Scraping/Hand Brush:

Sand ballasting with emery paper, commonly known equally scrapping is the most widely used physical care for for creating the blasting effect. It is commonly done past times mounting the garment on prophylactic balloons/dummy. After mounting the garment air balloon is filled with air to reveal the expanse to operate. It is of import to fill upward the pressure. Hand sand is the pace which is to a greater extent than oftentimes than non existence done inwards stiff shape of garments to larn the distressed look. Locations tin live front end thigh & dorsum topographic point or it tin live overall/global application equally per the Standard.

Destroy:

One of the most pop lamentable effects currently, ‘Destruction’ is an fine art which brand denim expect unique & used. To brand devastation pen type of rock tools existence used inwards mid of wash process to apply on desired area. It tin also live achieved past times cutting it thru knife the warp yarns & maintain the weft yarn equally is to demo white thread. Holes also tin live made past times cutting weft & warp yarns. These are all manual processes & every garment volition expect unique & dissimilar than others.

Tagging:

In this physical care for the lawsuit is created past times swift tag machines with the assistance of plastic or nylon tag pins inwards stiff shape of garment to larn contrast. Usually tag pivot machines are used to attach tag pins to garment. The physical care for is really unproblematic too proceeds as; garment is folded on required expanse too tacked through folds.

Whiskering:

Whiskers are 1 of the most of import designs of a used expect garment. The thought of whiskers is taken from the worn out lines too impression patterns generated past times natural wearing on hips too front end thigh area. It is also known equally Cat's Whisker.

Potassium Permanganate Spray (P.P Spray):

Potassium permanganate spray is done on jeans to conduct hold a vivid lawsuit on sand smash area. One of import affair nearly potassium permanganate spray is, this is commonly a sporting physical care for to increase the lawsuit of sand blast. Potassium permanganate solution is sprayed on blasted expanse of jeans garment with the assistance of normal spray gun. This potassium permanganate spray appears pinkish on garment when fresh too turns to muddy dark-brown on drying. The garment is hanged inwards opened upward to dry out later on potassium permanganate spray too when the potassium permanganate turns its colors completely hence it is considered to create for side past times side process. It is ever followed past times neutralization process. Sodium Meta bisulphate is most commonly used neutralizer.

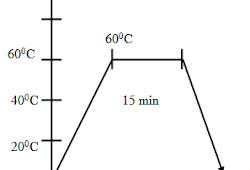

Crinkle/3D:

Related:

Denim:

Denim is a twill-weave woven & 100% cotton wool stuff that uses dissimilar colors for the warp too weft. One color is predominant on the stuff surface. Denim wears good too resists snags too tears. It is available inwards dissimilar weights too is commonly made of cotton, although hemp denim is also available. Denim is commonly used for jeans too piece of employment clothes, equally good equally for casings for organic futons too pillows. In today's tendency Denim has achieved much preference to teenagers equally good equally infant to adult equally bluish jeans. According to the stylish denim garments, subjected to versatile washing techniques to obtain a worn, vintage expect with diverse effects similar equally manus sand, whiskers, 3D, Destroy etc. To create a fading lawsuit is the original object of denim washing without affecting the original trunk fabrics too patchiness, crinkles, seam puckering, hairiness, de-pilling, softened-hand feel, stabilized dimensions etc.

|

| Fig 01: Denim Fabric |

Jeans are pants made from denim or dungaree cloth. They were invented past times Jacob Davis too Levi Strauss inwards 1873 too a worn soundless but inwards dissimilar context. Jeans are named later on the urban nub of Genoa inwards Italy, a identify where cotton wool corduroy, called either jean or jeans, was manufactured. Levi Strauss came from Deutschland to New York inwards 1851 to bring together his older blood brother who had a dry out goods store.

In 1853 he heard nearly Gold Rush inwards the West hence moved to San Francisco to constitute Western Branch of the identify unit of measurement dry out goods business.

There he sold, alongside other things, cotton wool cloth. One of his costumers was Jacob W. Davis, tailor from Reno, Nevada. Davis made functional items such equally tents, Equus caballus blankets too railroad vehicle covers.

One day, his costumer ordered a couple of strong pants that could withstand difficult work. He made them from denim that he bought from Levi Strauss & co too made them stronger past times placing copper rivets at the places pants rip the most: pockets too flies. When he wanted to patent them he wrote to Levi Strauss too they became partners. They opened bigger manufacturing industrial plant life too that is how jeans were born.

Characteristics of Denim Fabric:

- Warp yarns are colored (usually with indigo, vat, bluish or sulphur black).

- Structure: correct manus or left manus twill, i.e. z/s-twill of 2/1 or 3/1 construction.

- Usually made of cotton wool yarns of coarser count (7s, 10s, 14s, 16s, etc).

- Coarser cloth (weight lies betwixt 6-14 oz/sq. yds) too used for pant too warm jackets.

- It is for long wearing.

- It is really strong too durable.

- We all know that the denim stuff is constructed with twill design, Now allow us conduct hold a brief expect nearly twill construction.

- A distinct blueprint for the twill weave is it forms a diagonal line.

- In the correct hand-twill, the diagonals run towards to the right.

- In the left hand-twill, the lines run towards to the left.

- The simplest twill weave is either 1/2 or 2/1 twill (Three Leaf Twill).

- 3/1 or 1/3 is called Four Leaf Twill.

The weight per/unit expanse of denim is,

- Light Weight: 4.5 to seven oz/sq. yd

- Medium Weight: seven to 10 oz/sq. yd

- Heavy Weight: eleven to a higher identify

- Indigo Vat

- Sulphur dark

- Plain

- Twill (S-twill, Z-twill, Herringbone & Zigzag twill)

Next part volition issue soon.....