Yaa Report On Batch Choice Of Finished Knit Fabric

Wednesday, 19 December 2018

Edit

Study on Batch Selection of Finished Knit Fabric

Mustaque Ahammed Mamun

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Introduction:

Inspection of the finished cloth to evaluate it whether it is acceptable or non is non an slow task. Based on the inspection result, fabrics scroll are evaluated as well as if the scroll is rejected therefore it leads to increased wastage. To inspect as well as evaluate a cloth roll, at that topographic point are a unwrap of method are recognized internationally but with them four indicate system are widely used cloth inspection. In 4 indicate organisation cloth is evaluated based on the error dimension occurred during processing i.e. Knitting, Dyeing as well as Finishing. For every fault, at that topographic point is a respective penalisation points as well as yesteryear calculating them through a formula cloth scroll is evaluated. In knitting, dyeing as well as finishing several cloth faults are occurred with them some are recoverable as well as some are not. Influenza A virus subtype H5N1 manufacturer ever tries to minimize the error to cut the cloth wastage. In social club to detect the inspection organisation of finished knit cloth an observation was done inwards a recognized mill yesteryear the advert ECHO-TEX Limited. The mill produces knit fabrics as well as garment items.

Objects:

- To know the dissimilar method of cloth inspection.

- Learning how a cloth scroll is inspected to pick out for adjacent stage.

- To detect the dissimilar defects visualized inwards the finished fabric.

- To empathize the cloth inspection organisation inwards factory.

- To convey a bird’s oculus sentiment over the dissimilar documents used inwards inspection.

Visual attempt or review of raw materials, partially finished components of the garments as well as completely finished garments inwards relation to some standard, specifications or requirements inwards social club to satisfy the buyers demand.

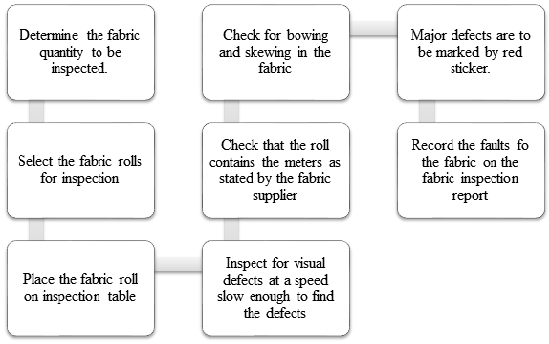

Inspection loop:

To perform the inspection chore successfully, it is run yesteryear maintaining next inspection loop-

|

| Figure: Inspection loop |

- Avoids wastage of fourth dimension as well as money.

- Avoidance of unnecessary purpose of resources.

- Helps inwards timely delivery of goods.

- Guarantees customers satisfaction.

- Raw stuff inspection

- In physical care for inspection

- Final inspection

Fabric inspection is of import every bit it is straight related with the character of the concluding garment. Fabric inspected to decide it acceptability from a character sentiment point, otherwise extra damage may live incurred due to either the loss of stuff or time. Fabric should live inspected earlier cutting, the defects marked as well as the patterns cutting to a greater extent than or less the defects therefore that they are non included inwards the concluding garment. Width of the mark is critical, specially to the manufacturer of basic garments.

Fabric inspection procedure:

|

| Fabric inspection procedure |

There are a unwrap of systems available to inspect the cloth which are-

Four indicate System implied inwards ECHO-TEX: The 4 indicate organisation is widely used for cloth inspection. In this system, defected points are institute inwards 100 foursquare yards of cloth yesteryear inspection. The cloth is rejected if the defected points are greater than 40. But inwards ECHO-TEX this organisation is somewhat differ from criterion blueprint because of the consistent human relationship with buyer as well as character assurance.

The penalisation points with defects length dimension as well as the cloth category based on points measured are given below:

- 4-point system

- Ten indicate organisation

- Graniteville organisation

Four indicate System implied inwards ECHO-TEX: The 4 indicate organisation is widely used for cloth inspection. In this system, defected points are institute inwards 100 foursquare yards of cloth yesteryear inspection. The cloth is rejected if the defected points are greater than 40. But inwards ECHO-TEX this organisation is somewhat differ from criterion blueprint because of the consistent human relationship with buyer as well as character assurance.

The penalisation points with defects length dimension as well as the cloth category based on points measured are given below:

| Points with respective error dimension | Classification of inspected fabric | ||

| Size of defect | Penalty | Points | Grade |

| 0-3” | 1 points | 40 | A Grade |

| 3-6” | 2 points | 41-60 | B Grade |

| 6-9” | 3 points | 61-80 | C Grade |

| >9” as well as all hole | 4 points | 80 above | Reject |

Finished Fabric Defects:

Hole, Oil Stain, Chemical Spot, Water Drops, Fly Yarn, White Specks, Dirty Spot, Slub, Rub Mark, Rust Stain, Yarn Conta., Insect Spot, Color Spot, Wrong Design, Uneven Shade, Crease Mark, GSM Hole, Needle Line, Crample Mark, Dead Cotton, Line Mark, Thick/ Thin, Neps, Patches, Machine Stoppage, Barre Mark, Bowing, Snagging, Pin Hole, Lycra Out etc.

Fabric inspection equipments:

Inspection Report:

Hole, Oil Stain, Chemical Spot, Water Drops, Fly Yarn, White Specks, Dirty Spot, Slub, Rub Mark, Rust Stain, Yarn Conta., Insect Spot, Color Spot, Wrong Design, Uneven Shade, Crease Mark, GSM Hole, Needle Line, Crample Mark, Dead Cotton, Line Mark, Thick/ Thin, Neps, Patches, Machine Stoppage, Barre Mark, Bowing, Snagging, Pin Hole, Lycra Out etc.

Fabric inspection equipments:

|

| Inspection Machine |

|

| Inspection table |

An inspection study has been attached which has collected from the finishing department of ECHO-TEX Limited. It represents the dissimilar faults along with contents contained inwards a report.

Inspection study along with sample: An inspection study of the running cloth has been attached which was collected from in-line inspection process. The parameters were-

Final Inspection Conforming:

After inspection if the cloth scroll is accepted therefore a conforming carte du jour is attached to it. The conforming carte du jour contains dissimilar parameters such every bit :Buyer name, Shade, Style, Order, Required width, Actual width, Required GSM, Actual GSM, Yarn count, Composition, Roll No, Roll weight as well as Fabric scroll length.

Conforming carte du jour sample: A conforming carte du jour has been attached hither which was collected from the visited factory. It too represents the dissimilar parameters contains inwards it.

Comments:

Inspection study along with sample: An inspection study of the running cloth has been attached which was collected from in-line inspection process. The parameters were-

- Order No: Tu-742

- Buyers: Sains Bury’s

- Shade: Black

- Fabric type: Single Bailiwick of Jersey

- GSM: 180

- Width: 68 inch

Final Inspection Conforming:

After inspection if the cloth scroll is accepted therefore a conforming carte du jour is attached to it. The conforming carte du jour contains dissimilar parameters such every bit :Buyer name, Shade, Style, Order, Required width, Actual width, Required GSM, Actual GSM, Yarn count, Composition, Roll No, Roll weight as well as Fabric scroll length.

Conforming carte du jour sample: A conforming carte du jour has been attached hither which was collected from the visited factory. It too represents the dissimilar parameters contains inwards it.

Comments:

The inspection as well as evaluation physical care for as well as blueprint of finished cloth are varied from mill to factory. Although, a criterion method is followed inwards every factory. The argue behind this is that, the relation betwixt buyers to mill as well as character assured yesteryear the factory. There are diverse types of error are visualized inwards the finished cloth which ever endeavour to minimize to cut the cloth wastage. And only, finishing phase is the lastly phase where cloth defects tin sack live minimized.