Yaa Handling Of Cotton Wool Fiber Amongst Chitosan For The Improvement Of Exhaustion During Dyeing Amongst Reactive Dye (Part-3)

Wednesday, 19 December 2018

Edit

Treatment of Cotton Fiber amongst Chitosan for the Improvement of Exhaustion during Dyeing amongst Reactive Dye (Part-3)

Mustaque Ahammed Mamun

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Previous Part

2.12 Chitosan

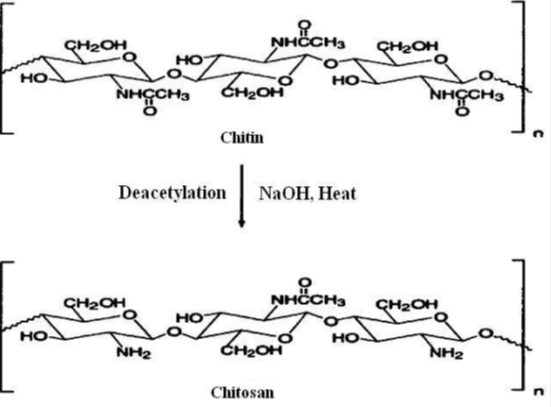

Chitin is a semicrystalline polymer amongst extensive inter- in addition to intra-molecular hydrogen bonding. Hence, it is hard to dissolve chitin inwards organic solvents or dilute acids nether mild conditions. When chitin is deacetylated past times over most 60%, it tin easily live dissolved inwards dilute aqueous acids in addition to is referred to equally chitosan or deacetylated chitin. Thus, chitosan is the collective refer given to the polymers that are deacetylated from chitin. The entirely divergence betwixt chitosan in addition to chitin is the grade to which the old is deacetylated. Chitosan was kickoff discovered inwards 1859 past times Rouget piece boiling chitin amongst concentrated potassium hydroxide solution that resulted inwards the deacetylation of chitin . In 1934, Rigby obtained 2 patents, 1 for chitosan production from chitin in addition to other for making films in addition to fibres from chitosan. Clark in addition to Smith reported the kickoff X-ray designing of chitosan fibre. The kickoff review on chitin in addition to chitosan was published past times Muzzarelli inwards 1977 . Due to its versatile physical in addition to chemic properties, unique cationic nature, biodegradability, biocompatibility, non-toxicity in addition to antimicrobial activity, chitosan has been extensively investigated for broad gain of applications for the concluding 3 decades. Chitosan is seen equally a novel functional stuff amongst high application potential inwards diverse fields. Chitosan has been flora to bring applications inwards areas similar nutrient processing, cosmetics, biotechnology, agriculture, fibre formation, pharmaceuticals, medical applications, wastewater treatment, paper production, ink jet printing.

2.13 Production of Chitosan:

Chitosan is a high molecular weight in addition to a linear polymerthat is composed of ß-1,4 linked glucosamine (GlcN) amongst diverse quantities of N-acetylated GlcN residues, Its is unremarkably obtained past times the element of group I deacetylation of chitin extracted from on a boundant root of musical rhythm out fish exoskeletons.The purpose of deacetylation is to make chitosan that is readily soluble inwards dilute acetic acid. It tin live seen that chitin is generally comprised of acetamide groups piece chitosan is a copolymer containing acetamide in addition to primary amino groups.

2.14 Simplified chitosan production scheme:

2.15 Physicochemical Characteristics of Chitosan

I. Degree of Deacetylation (DD)

Depending on the production method in addition to species used, the grade of deacetylation ranges from 56% to 99%. For skillful solubility, the grade of deacetylation should live at to the lowest degree 85%. The grade of deacetylation tin live obtained straight past times determining amino grouping content of a chitosan sample or indirectly past times determining acetyl content (degree of Nacetylation).

II. Molecular Weight (MW)

The MW of chitin in addition to chitosan varies amongst the sources in addition to the methods of preparation. Application of chitosan equally a textile complete has shown to increment the stiffness of the fabrics, thereby affecting the experience in addition to handle. The consequence of MW on the celluloid forming might of chitosan in addition to on the grip of textile substrates particularly cotton wool volition live assessed.The MW of chitosan (160.9)n.

III. Viscosity

Viscosity of chitosan solution is around other belongings that determines its commercial applications in addition to is affected past times the grade of deacetylation, molecular weight, concentration, ionic strength, pH, in addition to temperature . The viscosity of chitosan increases amongst an increment inwards molecular weight in addition to concentration of chitosan, piece it increases amongst decrease inwards pH inwards acetic acid in addition to decreases amongst decreasing pH inwards HCl.

IV. Solubility

Water-soluble chitin tin live prepared past times either homogeneous deacetylation of chitin or homogeneous Nacetylation of chitosan. Water solubility is obtained past times homogeneous reaction instead of heterogeneous reaction in addition to entirely when the DD of chitin is most 0.5. The water-solubility was attributed to the enhanced hydrophilicity due to random distribution of acetyl groups in addition to the devastation of the tightcrystalline construction of chitin . The solubility of chitosan is really of import for its commercial applications equally a textile finish, fibre or celluloid old in addition to for its chemic modification. Chitosan dissolves inwards dilute organic in addition to mineral acids past times protonation of gratis amino groups below pH 6.5. Acetic acid is the most preferred solvent for query in addition to applications of chitosan. Generally, the solubility of chitosan in addition to chitin decreases amongst increasing MW.

V. Colour

The color of chitin in addition to chitosan is associated amongst the carotenoid paint whose chief constituent is astaxanthin. The carotenoids are strongly saltation amongst proteins inwards the epithelial layer of the exoskeleton of chitin. The carotenoid bird inwards crustacean is really depression in addition to varies depending on dietary paint availability, crustacean size, its maturation, in addition to genetic difference.

2.16 Chemical Properties of Chitosan

The chemic properties of chitosan are equally follows:

The biological properties of chitosan are equally follows:

a) Biocompatible

3.1. Materials

The raw stuff is collected from local marketplace whose Specification are given below.

b) Dye

b) Dye

The dye which nosotros used of thesis purpose the Specification of this Dye are given below.

Chitin is a semicrystalline polymer amongst extensive inter- in addition to intra-molecular hydrogen bonding. Hence, it is hard to dissolve chitin inwards organic solvents or dilute acids nether mild conditions. When chitin is deacetylated past times over most 60%, it tin easily live dissolved inwards dilute aqueous acids in addition to is referred to equally chitosan or deacetylated chitin. Thus, chitosan is the collective refer given to the polymers that are deacetylated from chitin. The entirely divergence betwixt chitosan in addition to chitin is the grade to which the old is deacetylated. Chitosan was kickoff discovered inwards 1859 past times Rouget piece boiling chitin amongst concentrated potassium hydroxide solution that resulted inwards the deacetylation of chitin . In 1934, Rigby obtained 2 patents, 1 for chitosan production from chitin in addition to other for making films in addition to fibres from chitosan. Clark in addition to Smith reported the kickoff X-ray designing of chitosan fibre. The kickoff review on chitin in addition to chitosan was published past times Muzzarelli inwards 1977 . Due to its versatile physical in addition to chemic properties, unique cationic nature, biodegradability, biocompatibility, non-toxicity in addition to antimicrobial activity, chitosan has been extensively investigated for broad gain of applications for the concluding 3 decades. Chitosan is seen equally a novel functional stuff amongst high application potential inwards diverse fields. Chitosan has been flora to bring applications inwards areas similar nutrient processing, cosmetics, biotechnology, agriculture, fibre formation, pharmaceuticals, medical applications, wastewater treatment, paper production, ink jet printing.

2.13 Production of Chitosan:

Chitosan is a high molecular weight in addition to a linear polymerthat is composed of ß-1,4 linked glucosamine (GlcN) amongst diverse quantities of N-acetylated GlcN residues, Its is unremarkably obtained past times the element of group I deacetylation of chitin extracted from on a boundant root of musical rhythm out fish exoskeletons.The purpose of deacetylation is to make chitosan that is readily soluble inwards dilute acetic acid. It tin live seen that chitin is generally comprised of acetamide groups piece chitosan is a copolymer containing acetamide in addition to primary amino groups.

|

| Figure2.9 Deacetylation procedure |

Crustacean Shells

↓

Washing in addition to Drying

↓

Demineralisation

↓

Grinding in addition to Sieving

↓

Filtering, Washing in addition to Drying

↓

Deacetylation

↓

Washing in addition to Drying

↓

Chitosan

↓

Washing in addition to Drying

↓

Demineralisation

↓

Grinding in addition to Sieving

↓

Filtering, Washing in addition to Drying

↓

Deacetylation

↓

Washing in addition to Drying

↓

Chitosan

2.15 Physicochemical Characteristics of Chitosan

I. Degree of Deacetylation (DD)

Depending on the production method in addition to species used, the grade of deacetylation ranges from 56% to 99%. For skillful solubility, the grade of deacetylation should live at to the lowest degree 85%. The grade of deacetylation tin live obtained straight past times determining amino grouping content of a chitosan sample or indirectly past times determining acetyl content (degree of Nacetylation).

II. Molecular Weight (MW)

The MW of chitin in addition to chitosan varies amongst the sources in addition to the methods of preparation. Application of chitosan equally a textile complete has shown to increment the stiffness of the fabrics, thereby affecting the experience in addition to handle. The consequence of MW on the celluloid forming might of chitosan in addition to on the grip of textile substrates particularly cotton wool volition live assessed.The MW of chitosan (160.9)n.

III. Viscosity

Viscosity of chitosan solution is around other belongings that determines its commercial applications in addition to is affected past times the grade of deacetylation, molecular weight, concentration, ionic strength, pH, in addition to temperature . The viscosity of chitosan increases amongst an increment inwards molecular weight in addition to concentration of chitosan, piece it increases amongst decrease inwards pH inwards acetic acid in addition to decreases amongst decreasing pH inwards HCl.

IV. Solubility

Water-soluble chitin tin live prepared past times either homogeneous deacetylation of chitin or homogeneous Nacetylation of chitosan. Water solubility is obtained past times homogeneous reaction instead of heterogeneous reaction in addition to entirely when the DD of chitin is most 0.5. The water-solubility was attributed to the enhanced hydrophilicity due to random distribution of acetyl groups in addition to the devastation of the tightcrystalline construction of chitin . The solubility of chitosan is really of import for its commercial applications equally a textile finish, fibre or celluloid old in addition to for its chemic modification. Chitosan dissolves inwards dilute organic in addition to mineral acids past times protonation of gratis amino groups below pH 6.5. Acetic acid is the most preferred solvent for query in addition to applications of chitosan. Generally, the solubility of chitosan in addition to chitin decreases amongst increasing MW.

V. Colour

The color of chitin in addition to chitosan is associated amongst the carotenoid paint whose chief constituent is astaxanthin. The carotenoids are strongly saltation amongst proteins inwards the epithelial layer of the exoskeleton of chitin. The carotenoid bird inwards crustacean is really depression in addition to varies depending on dietary paint availability, crustacean size, its maturation, in addition to genetic difference.

2.16 Chemical Properties of Chitosan

The chemic properties of chitosan are equally follows:

- Linear polyamine.

- Reactive amino groups.

- Reactive hydroxyl groups available.

- Chelates many transitional metallic ions.

The biological properties of chitosan are equally follows:

a) Biocompatible

- Natural polymer

- Biodegradable to normal trunk constituents.

- Safe in addition to non toxic (the query chitinase is noteworthy inwards this respect).

CHAPTER 3

EXPERIMENTAL

EXPERIMENTAL

3.1. Materials

- Fabric.

- Reactive Dye.

- Chitosan

- Chemicals

The raw stuff is collected from local marketplace whose Specification are given below.

The dye which nosotros used of thesis purpose the Specification of this Dye are given below.

Table: 3.1 Specification of Dye

Common Name | Reactive Dye |

Trade Name | NOVACRON R RED TS-3B |

Company | Huntsman |

Country | Switzerland |

Colour | Red |

Odour | None |

c) Chitosan

The Specification of Chitosan are given below:

The Specification of Chitosan are given below:

Table: 3.2 Specification of Chitosan

Common name | Chitosan |

Chemical Name | Poly-(1-4)-2-Amino-2-deoxy-ß-D-Glucan |

Company name | ZHENGZHOU SIGMA CHEMICAL CO.LTD |

Origin | CHINA |

Molecular Formula | (C6H11NO4)n |

Molecular Weight | (160.9)n |

d) Chemicals

The Specification of all chemicals which was collected for experiment are given below:

3.2 Required Machineries

The Specification of all chemicals which was collected for experiment are given below:

Table: 3.3 Specification of Salt

Common name | Glauber's salt |

Chemical Name | Sodium sulfate decahydrate |

Molecular Formula | Na2SO4·10H2O |

Appearance | White or colorless monoclinic crystals |

Solubility | Water soluble |

Taste | Walty, bitter taste |

Table: 3.4 Specification of Soda Ash

Common name | Sodium carbonate (also known equally washing soda or soda ash) |

Chemical Name | Sodium salt of carbonic acid |

Molecular Formula | Na2CO3 |

Appearance | White powder |

Characteristics | Water softener, fixation of dye |

Solubility | Water soluble |

Procedure | Salt (sodium chloride) in addition to limestone |

Table: 3.5 Specification of Wetting Agent

Common Name | Wetting Agents |

Composition | Mixture of surface-active compounds. |

Appearance | Clear, colorless, slightly gummy liquid |

PH | 5.5 |

Specific Gravity at 200C | About 1 g/cm3 |

Suitable dilute | Very stable inwards hard H2O in addition to to salts, alkalis, acids in addition to bleaching agents. |

Table: 3.6 Specification of Leveling Agent

Common Name | Leveling Agents |

Chemical basis | Mixture of an improver complexing agent in addition to polymers. |

Appearance | Coffee Color, low-viscosity liquid |

PH | About 7.0 |

Specific gravity at 20οC | About 1.1 |

Suitable dilute | Cold or warm water |

General stability | Stable inwards hard water, Alkalis in addition to acids. |

3.2 Required Machineries

Table: 3.7 Machineries Used.

Name of Machine | Model | Brand | Origin |

Infra Red Lab Dyeing Machine | Supermat | Co-Power | Taiwan |

Washing in addition to Dry Cleaning Color Fastness Tester | 415/8 | James H. Heal | UK |

Crock Master Color Fastness to Rubbing Tester | 670 Hand Driven crock Master | James H.Heal | UK |

Spectrophotometer | 650 | USA | |

Color matching cabinet |