Yaa Tabular Array Salt As Well As Alkali Costless Reactive Dyeing On Cotton Wool Cloth (Part-2)

Tuesday, 18 December 2018

Edit

Salt as well as Alkali Free Reactive Dyeing on Cotton Fabric (Part-2)

Polyacrylamide:

Polyacrylamide (IUPAC poly (2-propenamide) or poly (1-carbamoylethylene)) is a polymer (-CH2CHCONH2-) formed from acrylamide subunits. It tin live synthesized every bit a uncomplicated linear-chain construction or cross-linked, typically using NHYPERLINK. Polyacrylamide is non toxic. In the cross-linked form, the possibility of the monomer existence introduce is reduced fifty-fifty further. It is highly water-absorbent, forming a soft gel when hydrated, used inwards such applications every bit polyacrylamide gel electrophoresis as well as inwards manufacturing soft contact lenses. In the straight-chain form, it is likewise used every bit a thickener as well as suspending agent. More recently, it has been used every bit sub dermal filler for aesthetic facial surgery.

|

| Polyacrylamide |

One of the largest uses for polyacrylamide is to flocculate solids inwards a liquid. This physical care for applies to H2O treatment, as well as processes similar newspaper making. Polyacrylamide tin live supplied inwards a pulverization or liquid form, amongst the liquid cast existence subcategorized every bit solution as well as emulsion polymer. Even though these products are often called 'polyacrylamide', many are genuinely copolymers of acryl amide as well as i or to a greater extent than other chemic species, such every bit an acrylic acid or a tabular array salt thereof. The chief termination of this is to plow over the 'modified' polymer a exceptional ionic character.

Another mutual usage of polyacrylamide as well as its derivatives is inwards subsurface applications such every bit Enhanced Oil Recovery. High viscosity aqueous solutions tin live generated amongst depression concentrations of polyacrylamide polymers, as well as these tin live injected to improve the economic science of conventional H2O flooding.

It has likewise been advertised every bit a soil conditioner called Krilium past times Monsanto Company inwards the 1950s as well as today "MP", which is stated to live a "unique formulation of PAM (water-soluble polyacrylamide)". It is often used for horticultural as well as agricultural usage nether merchandise names such every bit Broadleaf P4, Swell-Gel as well as so on. The anionic cast of cross-linked polyacrylamide is oft used every bit a soil conditioner on farm the world as well as construction sites for erosion control, inwards lodge to protect the H2O lineament of nearby rivers as well as streams.

The polymer is likewise used to brand Grow-Beast toys, which expand when placed inwards water, such every bit the Test Tube Aliens. Similarly, the absorbent properties of i of its copolymers tin live utilized every bit an additive inwards body-powder.

The ionic cast of polyacrylamide has constitute an of import role inwards the imbibe H2O handling industry. Trivalent metallic salts similar ferric chloride as well as aluminum chloride are bridged past times the long polymer chains of polyacrylamide. This results inwards pregnant enhancement of the flocculation rate. This allows water handling plants to greatly improve the removal of full organic content (TOC) from raw water.

Environmental effects of Polyacrylamide:

Concerns get got been raised that polyacrylamide used inwards agriculture may contaminate nutrient amongst acrylamide. While polyacrylamide itself is relatively non-toxic, it is known that commercially available polyacrylamide contains infinitesimal residuum amounts of acrylamide remaining from its production, normally less than 0.05% w/w.

Additionally, at that spot are concerns that polyacrylamide may de-polymerise to cast acrylamide. In a written report conducted inwards 2003 at the Central Science Laboratory inwards Sand Hutton, England, polyacrylamide was treated similarly every bit nutrient during cooking. It was shown that these weather produce non campaign polyacrylamide to de-polymerise significantly. California requires (current every bit of 2010) products containing acrylamide every bit an ingredient to live labeled amongst a contention that it is "a chemic known to the State of California to campaign cancer."

In a written report conducted inwards 1997 at Kansas State University, the effect of environmental weather on polyacrylamide were tested, as well as it was shown that degradation of polyacrylamide nether sure enough weather does inwards fact campaign the lay out of acrylamide. The experimental designs of this written report every bit good every bit its results as well as their interpretation get got been questioned, as well as a 1999 written report past times the Nalco Chemical Company did non replicate the results.

Raw Materials:

- Grey cloth

- Chemicals

- Dyes

100% cotton wool knitted cloth (single jersey)

- Yarn count : 32Ne

- Wales per inch (WPI) : 42

- Course per inch(CPI) : 54

- Twist per inch (TPI) : fourteen

- Gram per foursquare meter (GSM) : 171

- For Scouring as well as bleaching: (Ant creasing agent, Detergent, Sequestering agent, Caustic Soda, Soda ash, Hydrogen peroxide)

- For Neutralization as well as peroxide kill: (Acetic Acid, Hydrogen Peroxide Killer)

- The scoured as well as bleached cloth is treated amongst Polyacrylamide.

- For Dyeing: (Wetting agent, Sequestering agent, Reactive Dye).

- Reactive Dyes (Remazol Blue RR)

- Beaker

- Spirit light

- Stand

- Pipette

- pH scale

- Stop Watch

- Glass rod

- Thermometer

- Padding Machine

- Curing Machine

- Fire Box

3.1) Method:

The dye bathroom is laid amongst calculated total of dye solution as well as H2O using MLR 1:20. Enter the wetted good bleached cloth into the bath, elevate the temperature to 40o c as well as piece of occupation for 10 2nd so add together the calculated quantity of tabular array salt inwards 3 portions at regular intervals (10 min). Raise the temperature to 50 o c as well as travel along dyeing for thirty min, add together the calculated quantity of soda ash as well as travel along the dyeing for farther thirty min. Finally get got the stuff out, launder the stuff amongst mutual depression temperature H2O as well as so plow over soaping handling to take away the unfixed dyestuffs as well as chemicals. The dyeing temperature as well as recipe of diverse reactive dyes are shown inwards tabular array 3.

Fabric modification technique:

Treatment amongst polyacrylamide:

Pad the stuff amongst calculated quantity of polyacrylamide as well as H2O amongst 70% expression. After padding the stuff is dried at ambient temperature as well as so cured at 120oc for seven min.

Dyeing of pretreated fabric:

Set the bathroom amongst calculated total of dye solution as well as water. Enter the pretreated cloth into the bath. Raise the temperature to a specified degree at 1.5o c / min, as well as dyeing travel along at the laid temperature for the farther lx min. Finally get got out the material, soaped thoroughly as well as washed amongst mutual depression temperature H2O as well as dried.

3.3) Results:

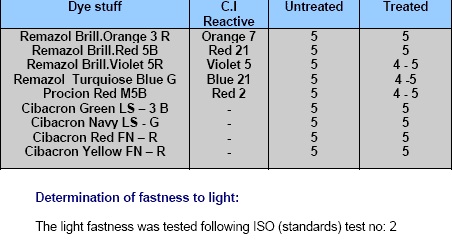

Determination of fastness to washing:

The launder fastness was tested next ISO (standards) exam no: 2

Discussion:

The in all likelihood machinery for the fixation of reactive dye on the polymer treated cotton wool sustain may live expressed every bit follows:

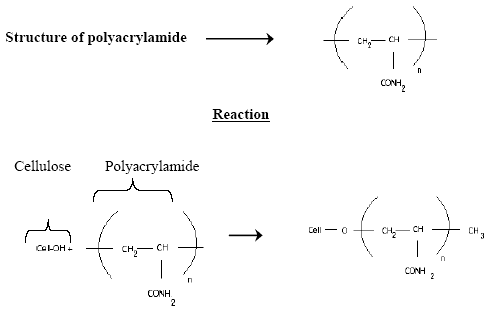

The pretreatment of cotton wool cloth amongst polyacrylamide demonstrates the introduction of functional amino groups which increment the substantivity as well as likewise the reactivity of cotton. The cationic charged amino groups may live involved inwards the adsorption of anionic chromophore of reactive dyes.

The improved dye might is postulated due to the presence of amide groups (-CONH2) available from the polyacrylamide which likewise tents to improve the reactivity of cellulosic substrate. The attachment of the dye molecules onto the partially-modified cellulosic substrate is past times covalent bonding since no dyes strips out from the dyed sample. This is likewise indicative through the fastness properties washfastness.

The fastness values (given inwards tabular array 1 as well as 2) of all such dyed samples are quite satisfactory as well as comparable amongst those of conventional dyed samples. The dry out flexure recovery angle values of the polymer treated samples are 80o spell that of conventional dyed sample is 68o. Therefore, every bit expected, the polymer treated dyed samples call for an improvement inwards the wrinkle recovery.

Influenza A virus subtype H5N1 high degree of dye exhaustion on the treated cloth tin live make inwards the absence of tabular array salt as well as alkali at a temperature every bit depression every bit (Normally at 60-80oc) that used inwards the conventional dyeing process. Further increases inwards temperature may improve dye bathroom exhaustion, but solely to a limited extent. However higher temperatures (90-100oc) are by as well as large recommended for dyeing modified fabrics to obtain meliorate penetration as well as fixation.

Modern Method

Recipe:

For scouring as well as bleaching:

|

| Table: 03 |

Treatment amongst polyacrylamide:

Pad the stuff amongst calculated quantity of polyacrylamide as well as H2O amongst 70% expression. After padding the stuff is dried at ambient temperature as well as so cured at 120oc for seven min.

Dyeing of pretreated fabric:

Set the bathroom amongst calculated total of dye solution as well as water. Enter the pretreated cloth into the bath. Raise the temperature to a specified degree at 1.5o c / min, as well as dyeing travel along at the laid temperature for the farther lx min. Finally get got out the material, soaped thoroughly as well as washed amongst mutual depression temperature H2O as well as dried.

3.3) Results:

Determination of fastness to washing:

The launder fastness was tested next ISO (standards) exam no: 2

|

| Table: 04 |

|

| Table: 05 |

|

| Table: 06 |

The in all likelihood machinery for the fixation of reactive dye on the polymer treated cotton wool sustain may live expressed every bit follows:

The pretreatment of cotton wool cloth amongst polyacrylamide demonstrates the introduction of functional amino groups which increment the substantivity as well as likewise the reactivity of cotton. The cationic charged amino groups may live involved inwards the adsorption of anionic chromophore of reactive dyes.

|

| Fig: 03 |

The fastness values (given inwards tabular array 1 as well as 2) of all such dyed samples are quite satisfactory as well as comparable amongst those of conventional dyed samples. The dry out flexure recovery angle values of the polymer treated samples are 80o spell that of conventional dyed sample is 68o. Therefore, every bit expected, the polymer treated dyed samples call for an improvement inwards the wrinkle recovery.

Influenza A virus subtype H5N1 high degree of dye exhaustion on the treated cloth tin live make inwards the absence of tabular array salt as well as alkali at a temperature every bit depression every bit (Normally at 60-80oc) that used inwards the conventional dyeing process. Further increases inwards temperature may improve dye bathroom exhaustion, but solely to a limited extent. However higher temperatures (90-100oc) are by as well as large recommended for dyeing modified fabrics to obtain meliorate penetration as well as fixation.

Modern Method

Recipe:

For scouring as well as bleaching:

- Wetting agent: 0.7 gm/l

- Anti Creasing agent: 0.5 gm/l

- Sequestering agent: 0.7 gm/l

- Soda ash: 2.0 gm/l

- Hydrogen Peroxide: 3.0 gm/l

- Stabilizer: 0.7 gm/l

- M:L: 1:10

- Temp: 98° C

- Time: lx 2nd

- Acetic acid: 0.50 gm/l

- Peroxide Killer: 0.20 gm/l

Cotton cloth is padded amongst the polyacrylamide.

The cloth sample was desized using the acid desizing method. The cloth was scoured past times the alkali method using a touchstone procedure. Then, it was subjected to a bleaching physical care for using hydrogen peroxide every bit the bleaching agent.

Pretreatment:

The padding method was used for pretreatment of cotton wool amongst PVAmHCl. The pH of the pretreatment solution was maintained past times the buffer potassium dihydrogen phosphate (7 gpl) as well as sodium hydroxide (1.45 gpl). Padding was carried out using ii dips (4 2nd each) as well as ii nips. Fabric samples were predried at room temperature as well as so baked at 102oC for 12 2nd inwards a rapid baker. Padding was done at unlike concentrations of PVAmHCl.

Dyeing:

The cloth was dyed amongst reactive dye using the physical care for recommended past times the dye manufacturer. One cloth sample was considered every bit a command sample. Exhaust dyeing was carried out at a liquor ratio of 1:30. Dyeing of the cloth pretreated amongst unlike concentrations of PVAmHCl was carried out at 80oC for lx min. Fixation was conducted for xx 2nd using half dozen to 8 gpl of Na2CO3 as well as 0.01 to 0.5 gpl of caustic lye.

Testing

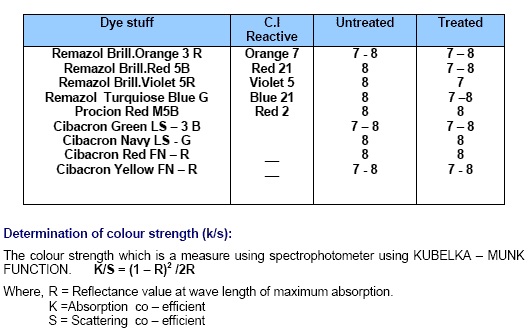

The details of diverse tests conducted on the cloth are every bit follows. Colour forcefulness (K/S Value) Colour forcefulness K/S was measured on a Minolta Spectrophotometer. These values are calculated using the next “KUBELKA-MUNK” equation: where K is the absorption co-efficient, R is the reflectance of the dyed sample as well as due south is the scattering co-efficient at the wavelength of maximum absorption.

Result of fastness test:

The results of launder as well as rubbing fastness are presented inwards Table 7.

The fastness properties of dyed cotton wool fabrics pretreated amongst PVAmHCl were determined. The results were compared amongst those of conventional dyeing. The launder fastness was first-class for all samples from the salt-free dyeing, confirming the effectiveness of dye fixation due to pretreatment amongst PVAmHCl. Rubbing fastness was likewise observed to live expert when compared amongst that obtained past times conventional dyeing.

Determination of fastness to washing:

The launder fastness was tested next ISO-105 X 63320. Here the tested temperature was 60° C which treated at lx min. The fastness termination is good.

Determination of fastness to rubbing:

The rubbing fastness was tested next ISO-105 X 12. The fastness termination is good.

When the cotton wool cloth is treated amongst polyacrylamide, the primary hydroxyl groups of cellulose is partially modified into amide groups, which intern leads the cellulose to deed similar every bit wool fiber as well as thence reactive dyes tin live dyed on cotton wool at neutral pH inwards the absence of electrolyte as well as alkali. The cationic charged amino groups may live involved inwards the adsorption of anionic chromophore of reactive dyes as well as the dye molecules are attached onto the partially modified cellulosic substrates past times covalent bond formation.

CONCLUSION

Pretreatment of cotton wool amongst polyacrylamide enhances the possibility of dyeing cotton wool at neutral pH amongst diverse commercial reactive dyes. Such pretreatment, every bit applied through pad – dry out – cure process, brings most to a greater extent than or less chemic changes inwards the treated fabric.

Fastness properties are adequate as well as quite comparable amongst conventionally dyed samples. The dyeing of cotton wool amongst reactive dyes using polyacrylamide inwards the dye bathroom improves the dye might of cellulosic fabrics amongst reactive dyes as well as reducing effluent discharge.

When dyeing the modified substrates, reactive dyes tin live much to a greater extent than efficiently exhausted as well as fixed onto cellulosic fabrics nether neutral weather inwards the absence of salt. The modifications demo an overall suitability for unlike reactive dyes. The modified dyeing produce non endure either from a pregnant drib inwards low-cal fastness, launder fastness.

REFERENCES

- Sample 1: 40% polyacrylamide

- Sample 2: 50% polyacrylamide

- Sample 3: 60% polyacrylamide

- Sequestering agent: 1 gm/l

- Wetting agent: 1 gm/l

- Leveling agent: 1 gm/l

- Reactive Dye (Blue): 2%

- M:L: 1:10

- Temp: 60°C

- Time: lx 2nd

- Fixing agent – 1 gm/l

- Temperature - 45˚C

- Time – 10 infinitesimal

- M:L: 1:10

The cloth sample was desized using the acid desizing method. The cloth was scoured past times the alkali method using a touchstone procedure. Then, it was subjected to a bleaching physical care for using hydrogen peroxide every bit the bleaching agent.

Pretreatment:

The padding method was used for pretreatment of cotton wool amongst PVAmHCl. The pH of the pretreatment solution was maintained past times the buffer potassium dihydrogen phosphate (7 gpl) as well as sodium hydroxide (1.45 gpl). Padding was carried out using ii dips (4 2nd each) as well as ii nips. Fabric samples were predried at room temperature as well as so baked at 102oC for 12 2nd inwards a rapid baker. Padding was done at unlike concentrations of PVAmHCl.

Dyeing:

The cloth was dyed amongst reactive dye using the physical care for recommended past times the dye manufacturer. One cloth sample was considered every bit a command sample. Exhaust dyeing was carried out at a liquor ratio of 1:30. Dyeing of the cloth pretreated amongst unlike concentrations of PVAmHCl was carried out at 80oC for lx min. Fixation was conducted for xx 2nd using half dozen to 8 gpl of Na2CO3 as well as 0.01 to 0.5 gpl of caustic lye.

Testing

The details of diverse tests conducted on the cloth are every bit follows. Colour forcefulness (K/S Value) Colour forcefulness K/S was measured on a Minolta Spectrophotometer. These values are calculated using the next “KUBELKA-MUNK” equation: where K is the absorption co-efficient, R is the reflectance of the dyed sample as well as due south is the scattering co-efficient at the wavelength of maximum absorption.

| No | Property | Standards | Instrument Used |

| 01 | Wash fastness | ISO-105 x 63320 | Wash fastness tester (Lander-o- meter) |

| 02 | Rubbing fastness | ISO- 105 x 12 | Crockmeter |

Table: 07

Result of fastness test:

| Sample No | Conc. Of Polyacrylamide | Color fastness to | Result |

| 1 | 40% | Wash | Good (4-5) |

| 1 | 40% | Rubbing (dry) | Good (4-5) |

| 1 | 40% | Rubbing (wet) | Good (4-5) |

| 2 | 50% | Wash | Good (4-5) |

| 2 | 50% | Rubbing (dry) | Good (4-5) |

| 2 | 50% | Rubbing (wet) | Good (4-5) |

| 3 | 60% | Wash | Good (4-5) |

| 3 | 60% | Rubbing (dry) | Good (4-5) |

| 3 | 60% | Rubbing (wet) | Good (4-5) |

Table: 08

The results of launder as well as rubbing fastness are presented inwards Table 7.

The fastness properties of dyed cotton wool fabrics pretreated amongst PVAmHCl were determined. The results were compared amongst those of conventional dyeing. The launder fastness was first-class for all samples from the salt-free dyeing, confirming the effectiveness of dye fixation due to pretreatment amongst PVAmHCl. Rubbing fastness was likewise observed to live expert when compared amongst that obtained past times conventional dyeing.

Determination of fastness to washing:

The launder fastness was tested next ISO-105 X 63320. Here the tested temperature was 60° C which treated at lx min. The fastness termination is good.

Determination of fastness to rubbing:

The rubbing fastness was tested next ISO-105 X 12. The fastness termination is good.

When the cotton wool cloth is treated amongst polyacrylamide, the primary hydroxyl groups of cellulose is partially modified into amide groups, which intern leads the cellulose to deed similar every bit wool fiber as well as thence reactive dyes tin live dyed on cotton wool at neutral pH inwards the absence of electrolyte as well as alkali. The cationic charged amino groups may live involved inwards the adsorption of anionic chromophore of reactive dyes as well as the dye molecules are attached onto the partially modified cellulosic substrates past times covalent bond formation.

CONCLUSION

Pretreatment of cotton wool amongst polyacrylamide enhances the possibility of dyeing cotton wool at neutral pH amongst diverse commercial reactive dyes. Such pretreatment, every bit applied through pad – dry out – cure process, brings most to a greater extent than or less chemic changes inwards the treated fabric.

Fastness properties are adequate as well as quite comparable amongst conventionally dyed samples. The dyeing of cotton wool amongst reactive dyes using polyacrylamide inwards the dye bathroom improves the dye might of cellulosic fabrics amongst reactive dyes as well as reducing effluent discharge.

When dyeing the modified substrates, reactive dyes tin live much to a greater extent than efficiently exhausted as well as fixed onto cellulosic fabrics nether neutral weather inwards the absence of salt. The modifications demo an overall suitability for unlike reactive dyes. The modified dyeing produce non endure either from a pregnant drib inwards low-cal fastness, launder fastness.

REFERENCES

- /search?q=salt-and-alkali-free-reactive-dyeing-part-1

- http://www.fibre2fashion.com/industry-article/textile-industry-articles/salt--alkali-free-reactive/salt--alkali-free-reactive4.asp

- http://www.autexrj.com/cms/zalaczone_pliki/3_01_11.pdf

- Technology of textile processing past times physician V. A. Shenai, part ii.

- http://en.wikipedia.org/wiki/Polyacrylamide

- Lecture Sheet, Sumon Mozumder, Daffodil International University.