Yaa Whitening Agent: Properties, Function, Machinery As Well As Usages (Part-6)

Tuesday, 18 December 2018

Edit

Whitening Agent: Properties, Function, Mechanism in addition to Usages (Part-6)

Authors: Md. Mosharaf Hossain

Kiriti Kingkar Mondal

Tawhidul Islam

Dept. of Textile Engineering

Primeasia University, Dhaka

Kiriti Kingkar Mondal

Tawhidul Islam

Dept. of Textile Engineering

Primeasia University, Dhaka

Previous Part

FBA for Cellulogic Fiber

Tiponal BV, 2B, GS, RBN, 4BM. Applied past times exhaustion or padding method. Exhausts at pH 8-11 or higher. Salt should endure used for exhausting Tiponal BV on the fiber. Tiponal 4BM is suitable for application past times the padding technique. Blancophor CL is intending for whitening cellulogic fiber. It is stable to Hydrochloride in addition to Chloride Bleach bath, in addition to then that it may endure applied piece bleaching alongside these bleaching agents. Fluorite BW stables alkaline metal hydrogen peroxide in addition to per tabular array salt bleach in addition to thus tin endure applied during bleaching. It tin endure applied past times exhaust dyeing method. Since it bring affinity for cellulogic fiber. Uvitex CK stable to difficult water.

FBA Polyester Fiber

Fluorite XMF intended for PES. Available inwards past times form. Applied at 100c alongside carrier. Thermosol used at heat pad-dry-bake process. Palanil white G liquid. Blancophor EBL of Bayer AG. Uvitex SEB-nonionic, micro fore aqueous dispersion all used inwards this purpose.

Process Requirements

Equipment Used:

Three types of Thies machines are used for whitening process. These are :

- Mini-soft

- Eco-soft

- Luft-roto

Key accessories used inwards whitening procedure are :

- Mixing tank

- Machine Tank

- Bohme meter

- pH meter

- Eye protecting glass

- Hand gloves

- Sewing machine

- Hand lifter for carrying the batch, in addition to

- Gum boot.

Following materials/chemicals are used inwards the whitening process:

- Water

- Steam

- Compressed Air

- Wetting agent

- Detergent

- Sequestering agent

- Acid

- Anti-creasing agent

- Optical Brightener for Cotton & Polyester

- Caustic Soda,

- Hydrogen per Oxide, in addition to

- Stabilizer, etc.

Whitening Process for 100% Cotton

The sequence for whitening procedure for 100% cotton fiber stuff is every bit follows:

- Take H2O inwards lavatory at required degree .

- Add Detergent, Sequestering Agent, Anti-creasing Agent, Stabilizer .

- Circulate the stuff for v minutes at 500C .

- Add Caustic Soda in addition to circulate for v minutes at 500C .

- Add Hydrogen per Oxide in addition to circulate for v minutes at 500C.

- Add Optical Brightener agent in addition to enhance the temperature at 1000C .

- Continue circulating the stuff for l minutes at constant temperature (1000C) .

- Circulate the stuff in addition to decrease the temperature at 600C .

- Check the shade alongside approved shade.

- Rinse in addition to Drain.

- Add Acetic acid in addition to circulate for 10 minutes at 500C.

- Drain .

- Unload .

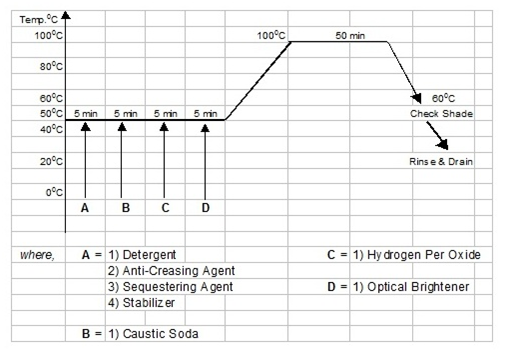

Graphical Representation of Whitening Process of 100% Cotton

The whitening procedure for 100% Cotton tin endure graphically presented every bit below :

The sequence of Whitening Process for Polyester-Cotton Blended stuff is every bit follows :

- Take H2O inwards lavatory at required degree

- Add Detergent, Sequestering Agent, Anti-creasing Agent, Stabilizer

- Circulate the stuff for v minutes at 500C

- Add Caustic Soda in addition to circulate for v minutes at 500C

- Add Hydrogen per Oxide in addition to circulate for v minutes at 500C

- Add Optical Brightener agent in addition to enhance the temperature at 1100C

- Continue circulating the stuff for thirty minutes at constant temperature (1100C)

- Circulate the stuff in addition to decrease the temperature at 600C

- Check the shade alongside approved shade

- Rinse in addition to Drain

- Circulate the stuff for 10 minutes at 800C

- Drain

- Add Acetic acid in addition to circulate for 10 minutes at 500C

- Drain

- Unload