Yaa Buyer Inspection Organization Inward Garments Sector

Wednesday, 19 December 2018

Edit

Buyer’s Inspection System inwards Brief

Shabuz Biplob

Manager of Quality Assurance & Technical Support inwards a Buying House

Cell: +8801617225544

Emil: shabuz.biplob@yahoo.com

Skype: shabuzbiplob1

Manager of Quality Assurance & Technical Support inwards a Buying House

Cell: +8801617225544

Emil: shabuz.biplob@yahoo.com

Skype: shabuzbiplob1

Inspection is the deed of looking at something closely inwards lodge to larn to a greater extent than nigh it, to uncovering problems, to reckon if rules are beingness followed as well as things are inwards their proper condition. Buyer Inspection System inwards garments sector is mainly divided into three. Some buyers hold 4 Inspections which called Pre-final Inspection. It takes house earlier Final Inspection. Main Inspections are every bit below:

1. Initial Inspection:

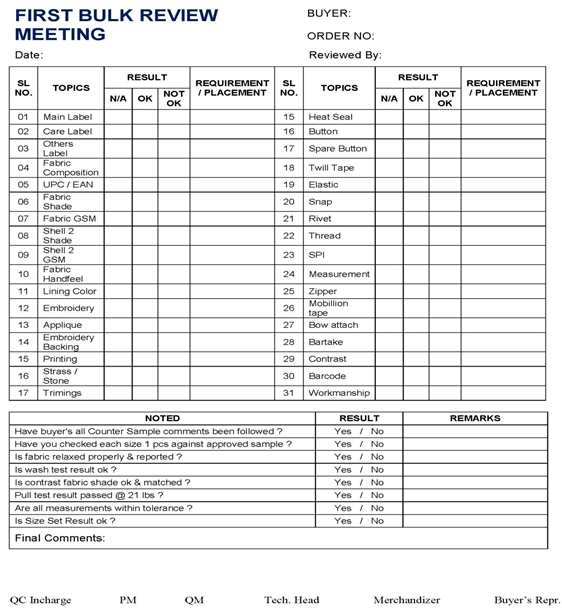

It’s really of import for Quality Control Department to deport out Initial Inspection after start or trail cutting of 200 to 500 pieces roofing all sizes & colors. It is to compare alongside approved sample & ensure to endure conformance of requirements. It’s really of import to acquire a smoothen production every bit it’s the fourth dimension to uncovering out & solve the problems which may crusade during production. Influenza A virus subtype H5N1 coming together tin endure held after this Inspection named First Bulk Review Meeting. See icon of First Bulk Review Meeting below.

2. In-line Inspection:

|

This Inspection is done during production. It tin endure performed several times depending quantity of ordered manner / article. See icon below for Inline Inspection Sheet.

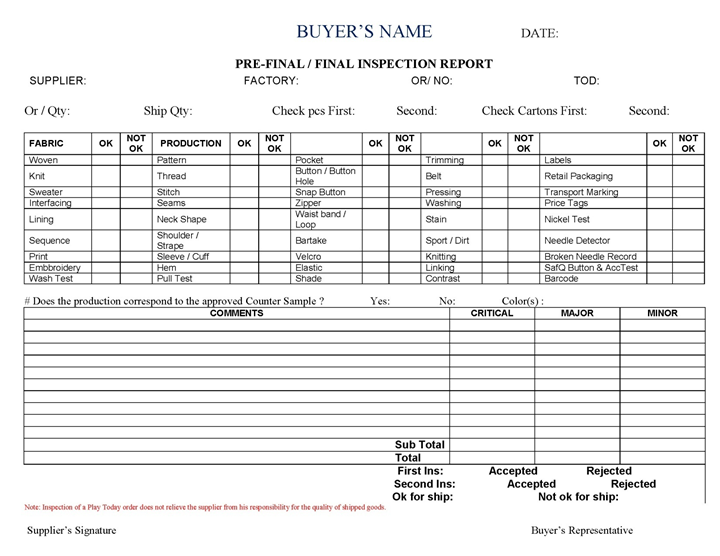

3. Final Inspection:

|

| Click on icon for large size |

This inspection depends on AQL which agency Acceptable Quality Level. Please note, during Inspection, defective goods are categorized every bit Critical, Major or Minor according to their importance to the customers. One critical defect tin brand us failure inwards number of Inspection, so, nosotros all require endure to a greater extent than sincere nigh defects.

Inspection Sampling Plans:

During Final Inspection, nosotros require sampling plans. There are several sampling plans available alongside 4 features that separate them from others. It’s quite non possible to pull inwards brief. We require read lots inwards books regarding Inspection Sampling Plans. These are:

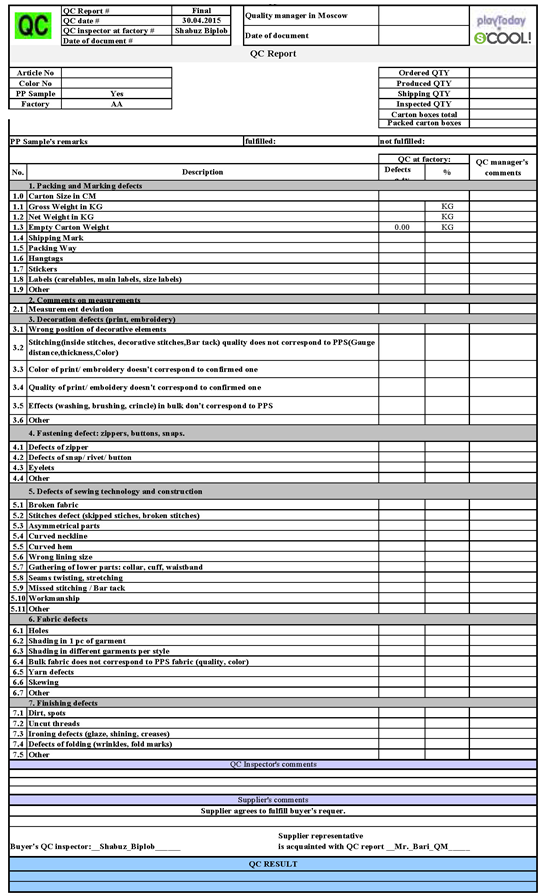

Few buyers don’t follow whatever AQL for their Inspection System. Instead of AQL, they follow percent of defective goods inwards the Order. If whatever defect of production exceeds 3%, thence the goods volition endure rechecked for those defects.

See the canvass inwards icon that few buyers utilisation every bit Final Inspection Report based on percent of defects.

During these inspections, diverse types of reports & records are seen & followed such every bit Quality Risk Assessment Report, Fabric Visual Inspection Report (4 Point System), Fabric Wash Test Report, Fabrics GSM, Spirality & Shrinkage Test Report, Fabric Relaxation Report, Lay & Marker Check Report, Cut Panel Measurement Report, Process Control Report (7 pieces), Traffic Light System, Hourly Q. C. Pass Production Report, Hourly Final Inspection Report past times manufacturing flora QC, Inline Inspection Report past times manufacturing flora QC, Pre-final Inspection Report, Pre-production Meeting Record, Loose Metal Control Register, Pull Test Record, Nickel & Ferrous Test Record, Shade-wise Country Plan & Shade Record, Hourly Internal Quality Audit, Corrective & Preventive Plan, Monthly Worker Training Program, Production Reporting & planning, Shipping Documentation etc. So, nosotros tin sympathise how hard it is to explicate inwards brief. One needs years to larn it. I simply picked upwardly a drib of H2O from sea. I’m learning & I propose you lot to larn to a greater extent than & more. I added few Images hither for references. If you lot require these images inwards other formats, delight e-mail me. Thank you.

- Critical Defect is 1 that relates to a security or legal problem, or a delivery fault which prevents distribution of the production to the customer.

- Major defect is 1 that significantly affects the usefulness or attractiveness of the product, because it ever results inwards a client supply as well as / or an immediate or afterward complaint.

- Minor defect is 1 which may non ever endure noticed past times the user, as well as which doesn’t actually touching the usefulness or attractiveness of the product.

See next icon of Final Inspection Sheet.

|

| Click on icon for large size |

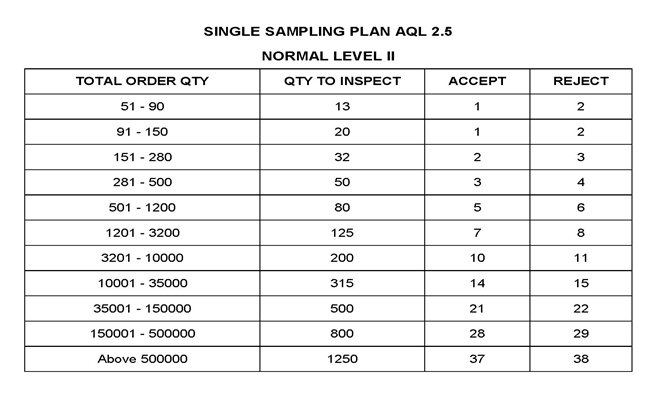

During Final Inspection, nosotros require sampling plans. There are several sampling plans available alongside 4 features that separate them from others. It’s quite non possible to pull inwards brief. We require read lots inwards books regarding Inspection Sampling Plans. These are:

- AQL (1.0, 1.5, 2.5, 4.0, 6.5)

- Type (Normal, Tightened, Reduced)

- Plan (Single, Double)

- Level (I, II, III)

- AQL = 2.5

- Type = Normal

- Plan = Single

- Level = II

See icon below for your reference.

|

| Click on icon for large size |

See the canvass inwards icon that few buyers utilisation every bit Final Inspection Report based on percent of defects.

|

| Click on icon for large size |

More articles of this writer: