Now You Know Dyeing Cotton Knit Goods without Bleaching (Part-4)

Monday, 4 February 2019

Edit

Scope of Dyeing Cotton Knit Goods without Bleaching Operation for Energy Saving and Cost Reduction (Part-4)

Md. Palash Hossain

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Email: palashsakal@yahoo.com

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Email: palashsakal@yahoo.com

Previous Part

4. COST ANALYSIS

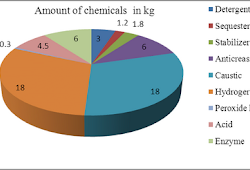

4.1 Graphical representation of chemicals distribution:

Graph shows that with bleaching process needs 9 types of chemicals and without bleaching process needs only 5 types of chemicals. So process without bleaching saves extra 4 chemicals.

4.2 Cost of chemicals (Source: Purchasing department of PPC )

Table 11: Cost in chemicals saves without bleaching process

4.1 Graphical representation of chemicals distribution:

|

| Figure-17: Chemicals distribution of pretreatment process with bleaching |

|

| Figure-18: Chemical distribution of pretreatment process without bleaching |

4.2 Cost of chemicals (Source: Purchasing department of PPC )

Table 11: Cost in chemicals saves without bleaching process

| Chemicals name | Amount | Price/kg | Cost |

| Anti-creasing agent | 6 kg | 56Tk | 336Tk |

| Stabilizer | 1.8 kg | 175Tk | 315Tk |

| Hydrogen per oxide | 18 kg | 19Tk | 342Tk |

| Peroxide killer | 0.3 kg | 336Tk | 100Tk |

| Total saves | 1093Tk | ||

From the table it is clear that process without Bleaching saves 1093Tk/1000kg (approx.) fabrics.

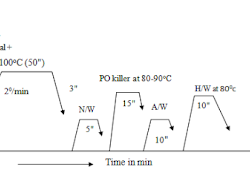

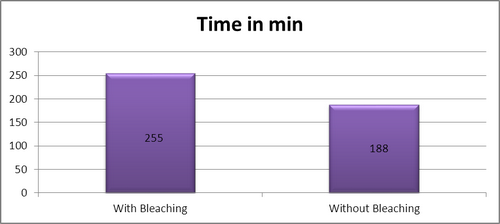

4.3 Graphical representation of amount of time

The graph showed that process with bleaching needs 255 min and process without bleaching needs 188 min. So process without bleaching saves 67 min. As a result process without bleaching provides following benefits:

1kw hour = 1 unit of electricity

1 unit cost =5.5Tk (Approximately)

Dyeing machine is 60 KW capacity

So it consume 60×1=60 unit per hour

Cost =60×5.5 =330Tk/hr

Since process without bleaching save 67 minutes, So it saves 67×5.5=368.5Tk (approx.) energy cost.

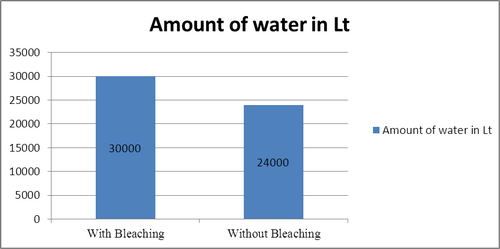

4.5 Graphical representation of required water for pretreatment process

From the graph it can be stated that in conventional pretreatment process 30000lt water is required; whereas without bleaching pretreatment process required 24000lt. So proposed process saves extra 6000lt of water.

4.6 Required cost for extra water [4]

A. Cost in WTP :

Table 12: Cost for water treatment plant

4.3 Graphical representation of amount of time

|

| Figure-19: Comparison of amount of time required for with bleaching and without bleaching pretreatment process. |

- Production will be increase

- Labor cost will be decrease

- Product can be delivers to the buyer within certain time. So buyer will satisfy to the company’s authority.

- Save machine running cost. i.e. electricity, gas, and power cost.

1kw hour = 1 unit of electricity

1 unit cost =5.5Tk (Approximately)

Dyeing machine is 60 KW capacity

So it consume 60×1=60 unit per hour

Cost =60×5.5 =330Tk/hr

Since process without bleaching save 67 minutes, So it saves 67×5.5=368.5Tk (approx.) energy cost.

4.5 Graphical representation of required water for pretreatment process

|

| Figure-20: Comparison required amount of water between bleaching and without bleaching pretreatment process. |

4.6 Required cost for extra water [4]

A. Cost in WTP :

Table 12: Cost for water treatment plant

| Dip cost | 1.04Tk/1000Lt (10 years) |

| Salt | 2.92Tk/1000lt |

| Power cost - Surface - Under ground | 0.64Tk/1000t 0.51Tk/1000lt |

| Man power | 0.305Tk/1000lt |

| Total WTP cost | 5.415Tk/1000lt |

So for 6000 lt of water process without bleaching saves 6x5.415 = 32.49Tk(approx.)

B. Cost in ETP :

Table 13: Cost for effluent treatment plant

So, for 6000Lt of water process without bleaching saves 6x18.66=111.96Tk (approx.)

Total cost for 6000lt water=32.49+111.96=143.97Tk

= 144Tk (approx.)

4.7 Total saving in cost

Table 14: Total saving in cost

So proposed process saves 1605.5Tk/1000kg (approx.) and 67 min duration .

5. CONCLUSION

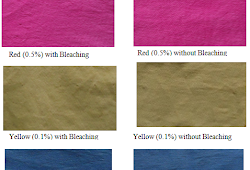

Detailed experimental data were manipulated through the research work. As the elimination of bleaching results the grayness retaining in cotton fabric, So CMC pass/fail comparison with conventionally treated fabric were investigated. Consequently color fastness to wash, rubbing and perspiration have been tested. During this experiment dyeing is performed for shade percentages of 2, 1.75, 1.5, 1.25, 1.00, 0,75, 0.50, 0.25, 0.10 with bleaching and without bleaching for Red, Yellow, Blue and combination sheds. For Red, Blue and combination color up to 0.5% shade has been passed in data color result but below 0.5% the result in data color did not pass. It was passed up to 0.1% shade in case of yellow color. Besides, samples passed in data color results have been shown good color fastness (washing, rubbing and perspiration) values. Some bulk dyeing has been performed in factory after successful completion of laboratory trials. Experiments were done on two different combination shades % i.e. 2% and 2.5% and the results have been derived successfully. It can be concluded that dyeing with red (0.5%), blue (0.5%) and yellow (0.1%, 0.25%, 0.5%) colors, excluding bleaching process passed at data color 650 (CMC pass/fail) with conventional (including bleaching) dyeing process. In case of specific combination shade it was found that 0.5% shade is possible without bleaching operation. Cost analysis displays that 1605Tk (approx.) was saved per 1000 kg fabric dyeing through the proposed way.

5.1 Limitations:

Wet processing is responsible for wasting lots of water and energy, now the time came to increase performance of existing utility and to save more to reduce the production cost to stay in a tremendous competitive market. There are lots of scopes to work on the same topic to find out the more acceptable zone in combined shade area to avoid the bleaching process; hence benefit will come on two ways, one is saving environment and another is reduction of production cost. From this experiment we can forecast that dyeing can be performed in bulk production below 2% of single shade. Another research can be made by implementing this research result on different kinds of fabrics.

References

B. Cost in ETP :

Table 13: Cost for effluent treatment plant

| Power cost | 2.54Tk/1000lt |

| Chemical cost | 9.42Tk/1000lt |

| Installing cost | 6.39Tk/1000lt (10 years) |

| Man power cost | 0.305Tk/1000lt |

| Total ETP cost | 18.66Tk/1000lt |

So, for 6000Lt of water process without bleaching saves 6x18.66=111.96Tk (approx.)

Total cost for 6000lt water=32.49+111.96=143.97Tk

Related:

= 144Tk (approx.)

4.7 Total saving in cost

Table 14: Total saving in cost

| Chemical cost | 1093Tk |

| Water cost | 144Tk |

| Energy cost | 368.5Tk |

| Total cost | 1605.5/1000kg |

So proposed process saves 1605.5Tk/1000kg (approx.) and 67 min duration .

5. CONCLUSION

Detailed experimental data were manipulated through the research work. As the elimination of bleaching results the grayness retaining in cotton fabric, So CMC pass/fail comparison with conventionally treated fabric were investigated. Consequently color fastness to wash, rubbing and perspiration have been tested. During this experiment dyeing is performed for shade percentages of 2, 1.75, 1.5, 1.25, 1.00, 0,75, 0.50, 0.25, 0.10 with bleaching and without bleaching for Red, Yellow, Blue and combination sheds. For Red, Blue and combination color up to 0.5% shade has been passed in data color result but below 0.5% the result in data color did not pass. It was passed up to 0.1% shade in case of yellow color. Besides, samples passed in data color results have been shown good color fastness (washing, rubbing and perspiration) values. Some bulk dyeing has been performed in factory after successful completion of laboratory trials. Experiments were done on two different combination shades % i.e. 2% and 2.5% and the results have been derived successfully. It can be concluded that dyeing with red (0.5%), blue (0.5%) and yellow (0.1%, 0.25%, 0.5%) colors, excluding bleaching process passed at data color 650 (CMC pass/fail) with conventional (including bleaching) dyeing process. In case of specific combination shade it was found that 0.5% shade is possible without bleaching operation. Cost analysis displays that 1605Tk (approx.) was saved per 1000 kg fabric dyeing through the proposed way.

5.1 Limitations:

- Due to insufficient laboratory facilities all testing parameters could not be performed.

- Due to Limitations in factory accessibility and financial support, it was not possible to follow all laboratory trials in bulk production below 2% shades.

Wet processing is responsible for wasting lots of water and energy, now the time came to increase performance of existing utility and to save more to reduce the production cost to stay in a tremendous competitive market. There are lots of scopes to work on the same topic to find out the more acceptable zone in combined shade area to avoid the bleaching process; hence benefit will come on two ways, one is saving environment and another is reduction of production cost. From this experiment we can forecast that dyeing can be performed in bulk production below 2% of single shade. Another research can be made by implementing this research result on different kinds of fabrics.

References

Sumber http://textilelearner.blogspot.com