Yaa Comprehensive Written Report On Loom Timing

Wednesday, 19 December 2018

Edit

Comprehensive Study on Loom Timing

Raju Tex

Production Executive, B.J.Group

Chittagong Textile Engineering College

Facebook: https://www.facebook.com/ERZRAZU

Production Executive, B.J.Group

Chittagong Textile Engineering College

Facebook: https://www.facebook.com/ERZRAZU

Loom Timing

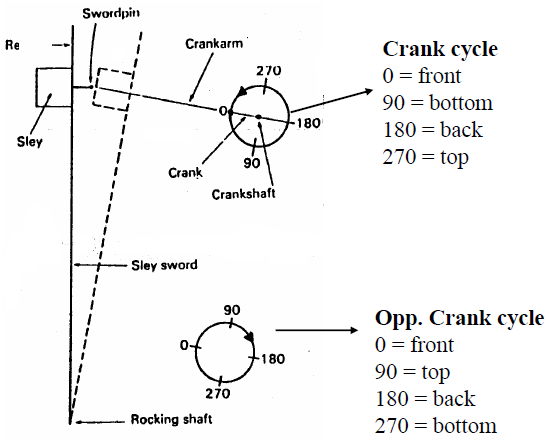

Loom timing is defined every bit relative chronological sequences of diverse primary too secondary motions are expressed inwards damage of marking of crank shaft rotation. The loom timing is presented past times a diagram termed every bit “Loom Timing Diagram”. The diagram depicts the outset too halt of each primary number of dissimilar weaving motions. The outset too halt of events are influenced past times loom type, cloth width too cloth type. The loom timing is shown inwards the Figure.

|

| Loom Timing Diagram |

Some others are related to it indirectly. For example. the timing of the weft intermission halt displace is related to the flying of the weft carrier, which is governed past times the seat of the reed. The timings on the weaving machine are stated inwards relation to the angular seat of the crankshaft (main shaft) which operates the sley.

The crank circle is graduated inwards degrees from this point inwards the management of rotation of the crankshaft. Any timing tin locomote stated inwards degrees, as, for example, ‘healds flat at 3000’

Looms are provided amongst a graduated disc on the crankshaft and a fixed pointer to brand settings inwards relation to the angular position of the crankshaft. With the reed inwards its almost frontwards position, the disc is adjusted so that the pointer is contrary to 00 on the graduated scale. The loom may too then locomote turned to whatever desired seat manually, the disc turning amongst it too the pointer remaining vertical too indicating the angular seat of the crank shaft. In modern looms amongst microprocessors, the principal shaft position is displayed on a screen, but the setting regulation remains same.