Yaa Written Report On Measure Spinning Testing Lab Equipments, Their Specifications In Addition To Functions

Wednesday, 19 December 2018

Edit

Study on Standard Spinning Testing Lab Equipments, Their Specifications together with Functions

Mustaque Ahammed Mamun

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Introduction:

In textile industry, row stuff is the most dominant component since it contributes 50-75% of full manufacturing cost. Any errors or negligence inwards pick together with composition of raw stuff cannot move corrected yesteryear whatsoever means. Here omissions are beyond redemption.

In instance of spinning manufacture the basic raw material is fiber which has a really high marking of variability. Its standard is actually a tough draw of piece of job but it is oft said that if 1 tin mensurate it thence together with solely thence he tin create out it.

To discovery the fiber testing instruments together with physical care for nosotros stimulate got visited the Amber Cotton Mills, Banglabazzar, Gazipur which is a leading lift inwards the textile sector of Bangladesh. They make high character knit yarn using the latest machinery. There cotton fiber yarn is automobile conned together with spliced with the best modern machineries. The cotton fiber yarn is Usterised together with electronically cleaned. Amber has a consummate make of latest USTER testing laboratory equipments.

Theory:

The character of cotton fiber varies considerably alongside the dissimilar varieties available. It is non slow to define character inwards absolute terms. The most of import fiber properties which decide the character of cotton fiber are its fiber length, fineness, maturity together with strength.

Testing is a valuable assistance to those connected to the production, distribution together with consumption of textiles, if the instruments together with techniques are used effectively. The right class of activity may move taken from the results of testing. Hence it tin move said that the testing is a agency to an end.

|

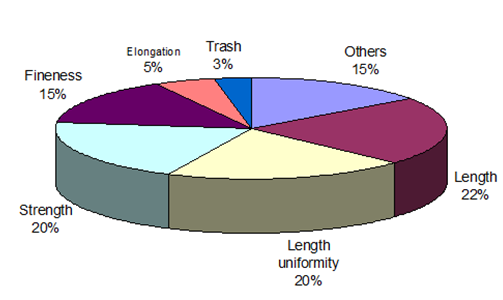

| Contribution of fiber properties to yarn character |

Testing is the application of technology scientific discipline noesis together with scientific discipline to the standard of the properties of textile fibers, yarns together with fabrics. It involves the usage of techniques, tools, instruments inwards the laboratory for the evaluation of the properties of these dissimilar forms of textiles.

Objects of the Assignment:

- To know almost diverse testing machines.

- To know almost the specifications of testing machines.

- To know almost diverse functions of testing machines.

- To net noesis almost Q/C department.

- To guess proper characters of diverse samples such every bit fiber, yarn, sliver.

- To assist diverse query for pick of raw material.

- For physical care for command & production control.

- Wrap Block.

- Wrap Reel.

- Electronic Balance.

- Lea Strength Tester.

- Twist Tester.

- USTER HVI grand

- USTER AFIS PRO.

- Evenness Tester: USTER Tester five (UT5).

- Yarn Moisture Meter.

- Digital Splicing Strength Tester.

Machine specification:

- Name: Wrap block

- Company: MAG

- Origin: Republic of Republic of India

Used for making Sliver together with roving lea together with count determination.

Necessary parameter:

Sample length (For sliver) = vi Yards

Sample length (For roving) = xxx Yards

Weight unit= Weight both for sliver together with roving is measured inwards grain.

Testing principle:

For sliver

6 yards sample is taken

↓

Wt of sample is measured inwards gr

↓

Then the wt is divided yesteryear vi to become gm/yd

For Roving

xxx yards sample is taken

↓

Wt of sample is taken inwards grain

↓

Then 250 is divided yesteryear the wt of sample to become the hank of sample.

For sliver

6 yards sample is taken

↓

Wt of sample is measured inwards gr

↓

Then the wt is divided yesteryear vi to become gm/yd

For Roving

xxx yards sample is taken

↓

Wt of sample is taken inwards grain

↓

Then 250 is divided yesteryear the wt of sample to become the hank of sample.

Experimental laid up:

|

| Fig: Wrap block machine |

Machine specification:

- Machine name: Wrap reel

- Company: MAG

- Origin: India

Used for making yarn lea together with count measurement.

Necessary parameter:

- Sample length: 120 yards

- Reel circumference: 1.5 yards

- Revolutions for making 120 yards yarn lea: lxxx

- Traverse length: 1.5 inch

Testing procedure:

120 yards sample is made yesteryear roll reel

↓

Wt of sample is measured inwards gm

↓

Then yesteryear adopting formula count is measured

120 yards sample is made yesteryear roll reel

↓

Wt of sample is measured inwards gm

↓

Then yesteryear adopting formula count is measured

Formula used:

Count (Ne) = 64.8/Lea weight inwards gram

Experimental laid up:

|

| Fig: Wrap reel machine |

Machine specification:

- Machine name: Lea forcefulness tester

- Model No: EleStretch XT

- Company: MAG

- Origin: India

Used for determining the forcefulness of yarn lea.

Necessary Parameter:

- Sample type: Yarn lea

- Sample length: 120 yards

- Clamp to clamp distance: 0.75 yards

- Strength unit: CSP (Count Strength Product)

Testing procedure:

120 yards sample is taken yesteryear Wrap reel

↓

Count is determined

↓

Then sample is laid inwards machine

↓

Machine is run

↓

After the sample beingness broken the reading (breaking tension inwards lb) is taken

↓

Then yesteryear adopting formula CSP is calculated

120 yards sample is taken yesteryear Wrap reel

↓

Count is determined

↓

Then sample is laid inwards machine

↓

Machine is run

↓

After the sample beingness broken the reading (breaking tension inwards lb) is taken

↓

Then yesteryear adopting formula CSP is calculated

Formula used for calculating CSP:

CSP=Count (Ne) X Breaking tension (lb)

Experimental laid up:

|

| Fig: Lea forcefulness tester |

Machine specification:

- Machine name: Automatic twist tester

- Company: MAG

- Origin: Republic of Republic of India

Used for checking the TPI inwards yarn.

Testing procedure:

20 inch sample is laid inwards machine

↓

Respective dead weight is inserted

↓

Machine run

↓

After the yarn beingness completely untwisted the machine is automatically stopped gives reading inwards display that indicates the TPI

20 inch sample is laid inwards machine

↓

Respective dead weight is inserted

↓

Machine run

↓

After the yarn beingness completely untwisted the machine is automatically stopped gives reading inwards display that indicates the TPI

Experimental laid up:

|

| Automatic twist tester |

Machine specification:

- Machine name: USTER HVI grand

- Company: Zellweger USTER

- Origin: Switzerland

Used for testing the dissimilar parameters of cotton fiber fiber.

Necessary parameter:

Measuring Sample weight: 9.5-10.5 gm

Modules:

- Length together with forcefulness

- Micronaire

- Color together with trash

- Spinning consistency index

- Micronaire

- Maturity index

- Upper one-half hateful length

- Uniformity index

- Short fiber index

- Strength

- Elongation

- Moisture

- Reflectance

- Yellowness

- Color marking

- Trash count

- Trash expanse

- Trash marking

SCI= -414.67 + 2.9 X Strength-9.32 X Micronaire + 49.17 X Length (inch) + 4.74 X Uniformity + 0.65 X Rd + 0.36 X b

Experimental laid up:

|

| USTER HVI grand |

Machine specification:

- Machine name: USTER AFIS PRO

- Company: Zellweger USTER

- Origin: Switzerland

Used for testing the dissimilar parameters of raw cotton fiber together with sliver.

Necessary parameter:

Measuring Sample weight = 0.40-0.60 gm

USTER AFIS PRO measures 3000 private fibers to hand a report.

Test Modules:

- NC( Nep classification) Module

- L & M( Length together with Maturity) Module

- T (Trash) Module

1. NC (Nep classification) Module:

- Nep count per gram

- Nep size (micron)

- Seed coat nep count per gram

- Seed coat nep size (micron)

- Mean length

- Mean length yesteryear weight

- Length variation yesteryear weight

- Upper quartile length yesteryear weight

- Short fiber content yesteryear weight

- Mean length yesteryear Number

- Short fiber content yesteryear give away

- Fineness(militex)

- Maturity ratio

- Immature fiber content

- Dust count per gram

- Dust size (micron)

- Trash size (micron)

- Visible unusual affair (%)

|

| USTER AFIS PRO |

Machine specification:

- Machine name: Evenness tester

- Company: Zellweger USTER

- Origin: Switzerland

Used for determining the evenness of sliver, roving together with yarn.

Experimental laid up:

|

| Evenness tester |

The to a higher house give-and-take gives an sentiment almost principal latest fiber testing techniques together with this concludes that 1 tin attain higher accuracy with to the lowest degree fourth dimension inwards this system. Fiber testing is an of import component inwards the finally product, thence it is clear 1 tin attain swell character with accurate testing techniques, which were discussed inwards this paper. Apart from this, diverse methods are also included which volition hand proper results inwards fiber testing.