Now You Know Whitening Agent: Properties, Function, Mechanism and Usages (Part-3)

Sunday, 3 February 2019

Edit

Whitening Agent: Properties, Function, Mechanism and Usages (Part-3)

Authors: Md. Mosharaf Hossain

Kiriti Kingkar Mondal

Tawhidul Islam

Dept. of Textile Engineering

Primeasia University, Dhaka

Kiriti Kingkar Mondal

Tawhidul Islam

Dept. of Textile Engineering

Primeasia University, Dhaka

Previous Part

Properties of Whitening Agent

Whiteness & Brightness

To the trained observer, even bleached are whit textile material has a slight yellow tinge. This small amount of yellow can give the impression of slight soiling and may detract from their aesthetic appeal the presence of slight amount of blue gives the impression that the textile material is whiter. Before advent of OBAs. Improved whiteness was obtained using a laundry blue, which is a blue pigment.

The development of OBAs had meant that this slight addition of blue can be obtained through the light reflected by the OBAs in the presence of ultraviolet radiation. This makes white textile whiter and brighter. Colored textile materials tend to appear brighter. OBAs are present in most domestic but these are usually only suitable for cellulosic textile material.

Light Fastness

There is large variation in the light fastness rating of these compounds when applied to cellulosic and protein fibers their light fastness range 1 to 2, and in some instance may reach 3. It should be pointed out that this poor light fastness is not too important in the cause of cellulosic’s, since any loss of OBAs effect due to sunlight will be replaced in subsequent laundering with domestic detergent. Fluorescent brighteners on xylon can reach a light fastness rating 4 with selected OBAs, a rating as high as 7 for polyesters, and in this class of acrylic fibers a light fastness of about 4 – 5.

|

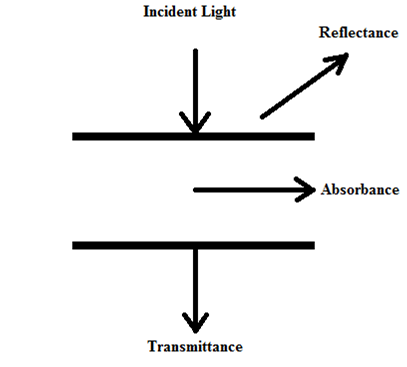

| Figure : Light-sheet interactions |

|

| Figure: Specular reflectance, B: Semi glossy-paper and C: Diffused reflectance (Re-drawn from Pauler 2002) |

Washing Fastness

The washing fastness rating of fluorescent brighteners if about 3. The fair washing fastness of fluorescent brighteners is due to partly to their lack of substantively of textile material and their gradual degradation by exposure to sunlight. The fair washing fastness may not be noticeable in cellulose because of the presence OBAs in domestic detergents when fluorescent are used on other fibers they are applied in the manufacturing situation and brighteners are chosen which will last the expected life of the textile article.

Metameric Effect of OBA

Metamerism is a normal phenomenon relating to how the human eye perceives color. It occurs when “two different color object have the same color appearance to normal human viewer under one light source ( metameric match ) but look different under another light source( metameric mismatch )” To a print marker, this means that the painstakingly precise color information applied to each print will be compromised whenever that print in viewed under a different light source. Thus, one primary goal of any print marker should be to avoid metamerism in order to validate the time spent on color management and to uphold the integrity of the reproduction. After all, what good is reproduction if it does? Now that we understand metamerism and why it should be avoided, how do OBAs fit into the picture? When OBAs are exposed to UV light, the treated paper appears brighter and whiter. When OBAs are not exposed to UV light (in the evening), the OBAs “lose activity” causing your eye to actually see the paper color without OBAs. This will look creamy or somewhat yellowed. This amount of “OBAs activity loss” will vary constantly depending upon how much exposure the paper has to UV light. Picture the lightening condition inside of an art gallery and how they will change depending upon the time of day. This will have subsequent effect on the art itself; your print could be illuminating the print. It a case like this, where there is a high UV component, inkjet papers that contain OBAs will strongly fluoresce and will appear bright white. However, in the evening when the same print is displayed with low or non – existent UV component (or incandescent tungsten illumination), the OBAs will not fluoresce, making the paper appear yellow, therefore causing your eyes to see the image color differently.

Fluorescence

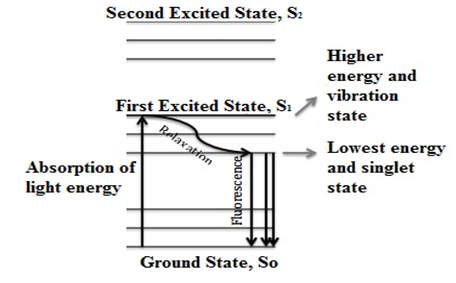

The ability of a substance to absorb light at a specific wavelength and emit it at a higher wavelength is called fluorescence. Optical brighteners or fluorescent whitening agents are added to improve the appearance properties (brightness, whiteness etc.) of printing and writing papers (Heikkilä et al. 1998). When light strikes a fluorescent material, some of the electrons acquire energy and a portion of energy is converted into heat. Thus, the emitted light has lower energy as compared to the incident light, which results in longer wavelengths (Hubbe et al. 2008). In contrast, non-fluorescent material either completely absorbs and converts such energy to heat, or instantly releases the energy by emitting light at a wavelength equal to the incident light (Hubbe et al. 2008).

|

| Figure 1.3 Energy diagram of fluorescent materials illustrating the energy transitions taking place within electronic orbitals (Re-drawn from Hubbe et al. 2008) |