Now You Know Implementation of Effluent Treatment Plants for Waste Water & Effect of Untreated on Environment (Part-1)

Tuesday, 22 January 2019

Edit

Implementation of Effluent Treatment Plants for Waste Water & Effect of Untreated on Environment (Part-1)

Rois U. Mahmud

Department of Textile Engineering

BGMEA University Of Fashion & Technology

Email: roisuddinhridoy@gmail.com

Department of Textile Engineering

BGMEA University Of Fashion & Technology

Email: roisuddinhridoy@gmail.com

ABSTRACT

The work is aimed on the implementation process of textile industries effluents & the present pollution scenario in Bangladesh due to textile effluent and the consequent solution of the problem by installation of effluent treatment plant. Despite of having ETP equipment almost all industries in Bangladesh most of them don’t implement the system because of huge expenses. On other hand the increasing industrialization is contributing severe pollution to the environment by the toxic waste discharge. The liquid effluents from industries are causing a major havoc to the environment, ecology, agriculture, aquaculture and public health since the development of textile industries in the country. It had become a prerequisite to set up ETP in each industrial establishment, particularly at dyeing industries that were discharging huge amount of liquid waste to the rivers every day. But, for the successful implementation of ETPs, industry owners will have to be socially responsible and at the same time, government should provide the factory owners with logistic supports and relaxed time frame to set up ETPs.

Keywords: Implementation process, Industrial Effluents; Water Quality; BOD; COD; TSS.

Introduction

Industrialization is an inevitable feature of economic intensification in a developing country. In the way of employment-intensive industrialization, textile industries are playing an utmost important role offering tremendous opportunities for the economy of Bangladesh. With the industrial development in Bangladesh, the waste management systems did not develop accordingly. Despite of having ETP equipment almost all industries are seen to discharge their wastes into water and on land without any treatment or after partial treatment. Of the environmental elements, water is the most affected as the big industries are usually situated on the river banks and due to continuous receiving of the effluents the toxicity of these river water increases day by day. The environmental pollution created by the industries has now become a burning issue of the nation (Bhuiyan, M.A.H. et. al., 2011) (Islam and Jolly, 2007) (Jolly and Islam, 2006). The major polluting industries like textile and dyeing, paints, tanneries, oil refineries, chemical complexes, fish processing units, fertilizer factories, cement factories, soap and detergent factories including light industrial units of Bangladesh discharge directly untreated toxic effluents in the rivers (Jolly, Ph. D.thesis, 2011). The textile dyeing wastes contain unused or partially used organic compounds, and high biochemical oxygen demand (BOD) and chemical oxygen demand (COD).

It is a positive sign that many industries are also making progress in establishing and operating their own ETPs to comply with national and international requirements, and also because of increased personal awareness of the negative impacts of industrial effluent.

Objectives

- To find out the implementation process of Effluent Treatment Plants of textile industries

- To find out the used chemicals data in ETP

- To find out the capacity of effluent treatment

- To find out the effect of untreated water on environment

For making a Research paper on the implementation process of ETP & effect of untreated water on environment under our Lecturer Mr. Rakib we made a visit at Niagara Textile LTD in Chandra, Gazipur. After went there one disappointing matter we faced that the authority didn’t give us any permission to take photo of ETP processes & units. We don’t know why they did that may be for their security purpose. Then we went to ETP plant & the instructor of ETP told us their ETP is a physico-chemical ETP plant.

With physico-chemical treatments generally used in Bangladesh (coagulation and flocculation) it is possible to remove much, possibly all of the color depending on the process used. It is however difficult to reduce BOD and COD to the value needed to meet the national effluent discharge standard, and impossible to remove TDS. The removal rate is dependent on the influent wastewater quality. The removal efficiency of this type of treatment has been found to be 50% and 70% for BOD and COD respectively.After that we knew about the process flow chart of the ETP and that is respectively screening, equalization tank, Sedimentation and Filtration, Chemical Unit Processes, PH controller, Aeration Tank, Coagulation and Flocculation, Secondary Clearifier & sludge collection Tank & Discharge Treated Water.We also know about the all chemicals are used to treat the waste water in Niagara. These are Fe(SO4),Ca(CO3),HCL & electro-polymer.We also collect the capacity of ETP. They treat about 120m3 water per hour,that mean they treat about 2880m3 water per day.At the final stage we saw the discharge & sludge tank and we collect the Data of discharge quality. After collecting the Data and monitoring the discharge water color & odor we have reached a decision on that the quality of discharge of Niagara is not so good. May be their waste water treatment is just like an Eye wash. And they give up the discharge into the local cannel.That’s why their low quality treated water may harm the cannel’s water.So that the authority should maintain the plant very carefully to treat the water purely.

We also know about another important matter that whole water source of Niagara is underground water. This is a really big matter of concern for our environmental balance of underground water. And another matter is, Niagara authority do not use the used water by recycling. So that day by day we may be loose our underground water level. So we recommend here to the authority to use the treated water by recycling. So that our water level may not go down day by day.

Methodology

In order to achieve the objectives of the study, an intensive field survey was conducted in Niagara textile industry in chandra, Gazipur.At starting point of our visit we first saw the dyeing process of the industry.Here we saw their conventional & modern dyeing machines used to dye the fabric. We informed here as for conventional machine they use 150L water per Kg fabric for dyeing & for modern machine they use 60to75L water per Kg fabric.And we also know about the capacity of their effluent treatment plant. Then we went to see the ETP and here we talk with the ETP instructor. He told us about their systems and processes of effluent treatment. He also told us about the chemicals they use for treating effluent. After that we went to see the whole process of ETP by our eye. At the end of the site we have examined the final water sample produce through ETP system(color) & how they manage that water and sludge. From the whole visit we collect the standard implementation process of ETP, Data of chemical they used, their management, standard rate of their final treated water& also find out how useful that water is for the environment etc.

Pollution Scenario Due to Textile Effluent

In Bangladesh, industrial units are mostly located at waterside. A complex mixture of hazardous chemicals, both organic and inorganic, is discharged into the water bodies from all these industries, usually without treatment. Thus, industrial units drain effluents directly into the rivers without any consideration of the environmental degradation.

Textile and dyeing industries produce wastewater, or effluent, as a bi-product of their products, which contains several pollutants originated from sizing, bleaching, mercerizing, fancy dyeing, screen printing, yarn dyeing and finishing. Chemicals used in these industries include acrylonitrile, chlorinated phenols, salicylanilide, organic mercurial compounds, and copper ammonium carbonate(3). Organic components degrade water quality during decomposition by depleting dissolved oxygen. The non- biodegradable organic components persist in the water system for a long time and pass into the food chain. In-organic pollutants are mostly metallic salts, and basic and acidic compounds. These inorganic components undergo different chemical and biochemical interactions in the river system, and deteriorate water quality.

In knit dyeing, the local textile dyeing industries higher amount of wastewater which varies from 150 - 330 liter per Kg of fabric, whereas the recommended amount of wastewater that can be discharged from composite textile dyeing industries is 100 liter per Kg fabric as per Environmental Conservation Rules, 1997 [4]. Disposal of these large amounts of wastewater with highly toxic compounds to water body and irrigable land is extensively threatening to the ecosystem and aquatic life and it also enters in our food chains. These lead to diminish the fisheries and agricultural economy day by day. The pollution leads to yield of poor quality of fish with the smell of chemicals. In general, pH of the effluent is found to above 11, which become lethal to all species of fish.

Again, the textile industries dispose large quantities of sulphates in their wastewater; this can be converted in the environment to hydrogen sulfide, a very poisonous gas. In addition, there is a large body of evidence that shows that residual textile dyes which go along with the waste-water can act as respiratory sensitizers and can lead to coughs, respiratory tract irritation ad asthma [4].

It is to be noted that, textile effluent comprises of large quantity of salt along with wastewater as dissolved solid. This salinity of the effluent is not removed by the conventional treatment of the effluent. So, with or without treatment, this wastewater disposed to the water system leads to increasing the salinity of water severely.

Thus, this indiscriminate discharge of untreated effluent to river deteriorates river water quality to unacceptable level and heavily impacts on water supply, human health, fisheries and agriculture. Recently, Government of Bangladesh (GoB) has conducted a study on survey of environmental pollution from industries in greater Dhaka, with the assistance of the United Nations Environmental Program (UNEP). Under the project, six clusters (Savar, Konabari, Tejgaon, Tongi, Hazaribagh and Narayangonj) are classified to undertake sampling and analysis the data to characterize wastewater.

|

| Waste water from dyeing mill |

## Implementation

# Effluent treatment methods:

At first we work with the method of effluent treatment method. Methods of effluent treatment may be classified into three main categories: physical, chemical and biological, as listed in Table [1]. Primary stages of treatment are mainly physical and include screening, sedimentation, flotation and flocculation to remove fibrous debris, undissolved chemicals and particulate matter. Primary treatment does not significantly remove color. Secondary stages are designed to eliminate the organic load and consist of a combination of physico-chemical separation and biological oxidation. Biological treatment does not remove sufficient color, COD and electrolytes to be satisfactory on its own but is often the least costly method of treatment. Physico-chemical separation depends on the forces of chemisorption to extract the colloidal organic compounds from the liquid phase. Tertiary stages of treatment have become more important but they make a major contribution to treatment costs. This stage is important for the removal of color and no one treatment will deal with the removal of all types of color.

Biological processes must be protected from shock loads of industrial pollutants, especially those containing toxic constituents. Preliminary stages include equalisation, neutralization and disinfection. Major reasons for poor results from settling tanks include significant fluctuations in flow, temperature and composition of waste liquors which cause convection currents and stratification in the tanks and interfere with normal sedimentation. Balancing of flow and composition together with cooling or heat recovery is necessary. Disinfection with chlorine may protect the micro-organisms in the biological stage from toxic contamination.

Table 1 – Methods of effluent treatment

Physical | Chemical | Biological |

Sedimentation Filtration Flotation Foam fractionation Coagulation Reverse osmosis Solvent extraction Ionising radiation Adsorption Incineration Freezing Distillation | Neutralisation (HCL) Reduction Oxidation Catalysis Ion exchange Electrolysis (Polymer) | Stabilised ponds Aerated lagoons Trickling filters Activated sludge Anaerobic digestion Fungal treatment |

Our work site on which we work is a Physico-chemical Treatment Plant.

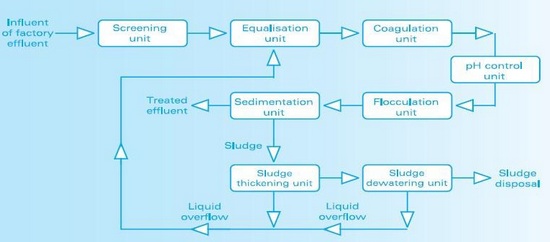

The basic units needed for a stand-alone physico-chemical treatment plant are screening, an equalization unit, a pH control unit, chemical storage tanks, a mixing unit, a flocculation unit, a settling unit and a sludge dewatering unit (Figure 1).

Figure 1: Typical Flow Diagram of a Physico-Chemical Treatment Plant in Bangladesh.

|

Part-2

You can also like:

- Water Consumption in Textile Industry

- Water Purification Process for Textile Wet Processing Industry

- Water Hardness Test Method

- Determination of Hardness of Water / Water Hardness

- Water Treatment Plant (WTP) | Process Sequence of Water Treatment Plant

- Characteristics of Effluent Water in Textile Wet Processing Industries

- Problem Caused by Hard Water in Wet Processing/Dyeing Industry

- Lime-Soda Water Softening Process

- Base Exchange (Ion Exchange) Water Softening Process

- Demineralization Process of Water Softening

- What is Hardness of Water? | Potential Problem Caused by Hard Water in Textile Wet Processing Industry

- Some Important Parameters of Water for Textile Wet Processing Industry

- Implementation of Effluent Treatment Plants for Waste Water & Effect of Untreated on Environment

- Effluent Treatment Plant Process Sequence in Textile Industry

- Function of Different Units of Biological Effluent Treatment Plant (ETP)