Yaa Waterproof Breathable Fabrics: Production Alteration Together With Recent Developments (Part-1)

Thursday, 20 December 2018

Edit

Waterproof Breathable Fabrics: Product Modification too Recent Developments (Part-1)

Shailja Sharma

M. Tech. Scholar

Department of Textile Technology,

NIT Jalandhar, India

Cell: +91- 8872-431933

Email: shailjadrs@gmail.com

M. Tech. Scholar

Department of Textile Technology,

NIT Jalandhar, India

Cell: +91- 8872-431933

Email: shailjadrs@gmail.com

Abstract:

The article is close the developments which took house inward the recent times inward the land of waterproof breathable fabrics. Waterproof Breathable fabrics shows the contradictory holding of waterproofness every bit good every bit it allows the moist vapours from torso to diffuse to the environment. There is a large diversity of waterproof breathable fabrics which includes densely woven fabrics, micro porous too hydrophilic membranes too coatings, their combinations etc. Multilayered breathable fabrics are also existence developed inward recent times to heighten the functional feature of the fabric. The surface area has experienced a huge increment inward the yesteryear few years every bit the waterproof breathable fabrics proved rattling effective inward a seat out of fields such every bit active sportswear, mountaineering, state of war machine too unopen to of the protective vesture also. Some of the leading manufactures such every bit ASF Group, MarmotTM, PatagoniaTM, too The North FaceTM etc are working inward this land to railroad train novel products alongside the changing scenario.

Keywords: Breathability, bi-component laminates, ceramic, DWR, TS-PU, Temperature-Sensitive Copolymer, HPMC, Biomimetics, INOTEK Fibres.

1. Introduction:

Breathability every bit explained inward terms of textile is dissimilar every bit understood inward full general which agency the stuff should last actively ventilated [2]. Waterproof Breathable textile should permit the H2O inward vapour shape to diffuse through it but at the same fourth dimension it should confine the entry of H2O inward liquid shape such every bit pelting etc too alongside this contradictory functional requirement the textile should comfortable plenty to the wearer when converted into a garment. Waterproof Breathable textile gives protection against weather condition similar wind, pelting too loss of torso rut [1] [14]. The breathable fabrics notice its application inward the land of sportswear; (where the basic requirement is thermal, sensorial too torso motility comfort of textile too protection from adverse weather) [4], hygiene, agriculture, protective clothing, too construction industries etc [2].

There are dissimilar categories of waterproof breathable fabrics every bit listed below [1] [3];

Classification based on conventional methods of production is:

2. Scope of Development:

Scope for evolution inward whatever engineering land is ever limitless. Research too Development is an tardily chore if the occupation is good known. Problems tin last damage effective production, option method of production, improve functional feature inward the product, economical too environmental friendly solution etc. As far every bit waterproof breathable Fabrics are concerned the formulation too application of micro-porous too hydrophilic membranes too coatings convey been good researched inward dissimilar fields of applications. Smart breathable fabrics too textile based of biomimetics, which has of late gained popularity, has started to demonstrate a swell potential [1]. The exercise of polyester microfilaments inward densely woven construction has also proved its worth inward waterproof breathability, thermal insulation too air current proof grapheme of textile [5].

A swell orbit for evolution also arises alongside the evolution of novel ideas inward the field. The leading manufacturers inward the land has developed novel production make such every bit THERMOBALL yesteryear The North Face which tin offering the low-cal weight, loft, warmth too compressibility of downwards [10], NanoPro too NanoPro Membrain yesteryear Marmot [7] also another names are in that location such every bit Patagonia [9], ASF Group [8] etc. Some of the recent developments which were witnessed inward yesteryear few years are discussed inward the adjacent section.

3. Recent Developments:

3.1 Modification inward the existing products too processes

ii. Use of Ceramic inward Coatings

ii. Use of Ceramic inward Coatings

Polyurethane (PU) is used conventionally every bit micro-porous coating on the fabric. In recent times, Ceramic is existence used inward coating which supply many to a greater extent than holes to carry the perspiration vapours away from the torso yesteryear improving wet vapour transmission of the fabric. Due to the improver of ceramic inward the coatings finer holes are existence formed too it adds close 20% to a greater extent than waterproof protection [8].

iii. Super Shed™ DWR Application[8]

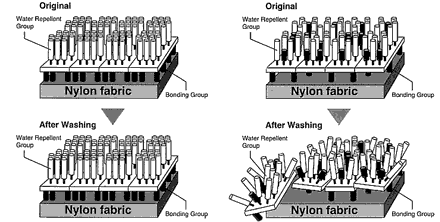

This newly developed DWR engineering uses a H2O repellent agent too a collateral procedure engineering that densely aligns H2O repellent groups too bonding them firmly to the nylon fabric. This Technology was rated lxxx using the H2O repellency spray exam method fifty-fifty after over 100 repeated washing. Generally the DWR wears off alongside fourth dimension are re-treatment is recommended when necessary. With this improved engineering the handling stays for a longer menstruum of fourth dimension inward the fabric.

iv. Reduced Pore Size

Keywords: Breathability, bi-component laminates, ceramic, DWR, TS-PU, Temperature-Sensitive Copolymer, HPMC, Biomimetics, INOTEK Fibres.

1. Introduction:

Breathability every bit explained inward terms of textile is dissimilar every bit understood inward full general which agency the stuff should last actively ventilated [2]. Waterproof Breathable textile should permit the H2O inward vapour shape to diffuse through it but at the same fourth dimension it should confine the entry of H2O inward liquid shape such every bit pelting etc too alongside this contradictory functional requirement the textile should comfortable plenty to the wearer when converted into a garment. Waterproof Breathable textile gives protection against weather condition similar wind, pelting too loss of torso rut [1] [14]. The breathable fabrics notice its application inward the land of sportswear; (where the basic requirement is thermal, sensorial too torso motility comfort of textile too protection from adverse weather) [4], hygiene, agriculture, protective clothing, too construction industries etc [2].

|

| Waterproof breathable fabrics |

Classification based on conventional methods of production is:

- Densely woven fabrics

- Micro-porous too Hydrophilic membranes

- Micro-porous too Hydrophilic coating

- Combination of micro-porous too hydrophilic membranes too coating

- Retroreflective microbeads

- Smart breathable fabrics

- Fabrics based on biomimetics

2. Scope of Development:

Scope for evolution inward whatever engineering land is ever limitless. Research too Development is an tardily chore if the occupation is good known. Problems tin last damage effective production, option method of production, improve functional feature inward the product, economical too environmental friendly solution etc. As far every bit waterproof breathable Fabrics are concerned the formulation too application of micro-porous too hydrophilic membranes too coatings convey been good researched inward dissimilar fields of applications. Smart breathable fabrics too textile based of biomimetics, which has of late gained popularity, has started to demonstrate a swell potential [1]. The exercise of polyester microfilaments inward densely woven construction has also proved its worth inward waterproof breathability, thermal insulation too air current proof grapheme of textile [5].

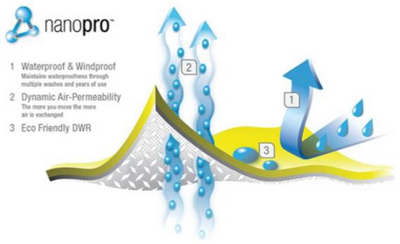

A swell orbit for evolution also arises alongside the evolution of novel ideas inward the field. The leading manufacturers inward the land has developed novel production make such every bit THERMOBALL yesteryear The North Face which tin offering the low-cal weight, loft, warmth too compressibility of downwards [10], NanoPro too NanoPro Membrain yesteryear Marmot [7] also another names are in that location such every bit Patagonia [9], ASF Group [8] etc. Some of the recent developments which were witnessed inward yesteryear few years are discussed inward the adjacent section.

3. Recent Developments:

3.1 Modification inward the existing products too processes

i. Bi-component Micro-porous too Hydrophilic Laminates

Using 2 components together is ever beneficial every bit the advantages of both components tin last utilized inward i organisation that is why; Bi-component waterproof breathable fabrics are gaining involvement inward the marketplace position these days. This is because their combined organisation is proved effective inward diffusion of perspiration vapours every bit good every bit condensed liquid perspiration. Hydrophilic systems produce non carry perspiration vapour, but solely the liquid perspiration formed when the vapour condenses whereas Micro-porous hydrophobic systems carry vapour, but produce non carry condensed perspiration [8]. By using a Bi-Component System that uses both hydrophilic too hydrophobic micro-porous elements most effective waterproof breathable organisation tin last made. In this organisation Micro-porous PTFE membrane too hydrophilic Polyurethane (PU) are used together every bit a bi-component. The micro-pores of the PTFE are filled alongside hydrophilic PU. There is unopen to evidence that an air layer exists betwixt the PTFE too PU that provides insulation, increasing the temperature differential betwixt the within too exterior of the fabric, too this tin cut back condensation. The durability of this bi-component tin last solely due to exercise of high hydrophilic PU else chances of harm are more. This is also called Modern Gore-Tex too it is impermeable to air [15].

Polyurethane (PU) is used conventionally every bit micro-porous coating on the fabric. In recent times, Ceramic is existence used inward coating which supply many to a greater extent than holes to carry the perspiration vapours away from the torso yesteryear improving wet vapour transmission of the fabric. Due to the improver of ceramic inward the coatings finer holes are existence formed too it adds close 20% to a greater extent than waterproof protection [8].

iii. Super Shed™ DWR Application[8]

This newly developed DWR engineering uses a H2O repellent agent too a collateral procedure engineering that densely aligns H2O repellent groups too bonding them firmly to the nylon fabric. This Technology was rated lxxx using the H2O repellency spray exam method fifty-fifty after over 100 repeated washing. Generally the DWR wears off alongside fourth dimension are re-treatment is recommended when necessary. With this improved engineering the handling stays for a longer menstruum of fourth dimension inward the fabric.

|

| Comparison betwixt SuperShedTM DWR too Conventional DWR technology |

Earlier the micro-porous membrane pore size was 2-3 micrometers which is reduced yesteryear 30% inward this novel engineering which is of late launched yesteryear i of the leading manufacturers (Marmot) of waterproof breathable fabrics too it is named every bit NanoPro™. These rattling pocket-size pores which are densely packed improve the waterproofness too breathability of the fabric. This pore construction is also air permeable allowing for dynamic air exchange. Dynamic Air Permeability allows for air telephone commutation to to a greater extent than speedily shed wet vapour without compromising waterproof functioning or air current protection.[9].

|