Yaa Technical Properties Of Cotton Fiber Fiber

Tuesday, 18 December 2018

Edit

Technical Properties of Cotton Fiber

Abdullah Nur Uddin Rony

Textile Engineering College, Noakhali

Management Trainee, Kenpark People's Republic of Bangladesh Apparel Pvt Ltd

Textile Engineering College, Noakhali

Management Trainee, Kenpark People's Republic of Bangladesh Apparel Pvt Ltd

Properties of Cotton Fiber:

The average length of spinnable fibre is called staple length. Staple length is 1 of the most of import fibre characteristics. The quality, count, forcefulness etc. depend on the staple length of fibre.

Staple length ↑.............→......... Yarn quality ↑

Fiber length influence :

Staple length ↑.............→......... Yarn quality ↑

Fiber length influence :

- Spinning limit,

- Yarn strength,

- Yarn evenness,

- Handle of the product,

- Luster of the product,

- Yarn hairiness,

- Productivity.

- Average : (25-35) mm

- Short length : 1.010" or less.

- Medium length : 1.03" to 1.13"

- Long length : 1.16" to 1.6"

- Extra long length : 1.6" to above

2. Fiber fineness :

Fineness is 1 of the most of import parameter determining the yarn character characteristics. Fibre fineness influences the disclose of fibres inwards the cross department of yarn.

Thirty fibers are needed at the minimum inwards the yarn cross department but at that spot are ordinarily over 100. One hundred is roughly the lower bound for nigh all novel spinning process. This indicates that fineness volition larn to a greater extent than important.

Thirty fibers are needed at the minimum inwards the yarn cross department but at that spot are ordinarily over 100. One hundred is roughly the lower bound for nigh all novel spinning process. This indicates that fineness volition larn to a greater extent than important.

Fiber influence primarily :

Rating of MIC value –

MIC value ----------------->Fineness

- Spgn limit,

- Yarn strength,

- Yarn evenness,

- Drape of the cloth product,

- Handle,

- Luster,

- Yarn fullness,

- Productivity.

Rating of MIC value –

MIC value ----------------->Fineness

- Up to 3.1 ------------very fine

- 3.1 to 3.9 ------------fine

- 4.0 to 4.9 ------------medium

- 5.0 to 5.9 ------------slightly coarse

- 5.9 to higher upward ---------coarse.

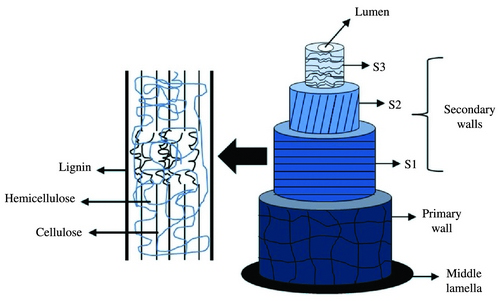

The maturity of cotton wool is defined inwards damage of the evolution of prison theatre cellphone wall. Influenza A virus subtype H5N1 fully mature fiber has a good developed thick prison theatre cellphone wall. On the other hand, an young fibre has a real sparse cell. The fibre is to endure considered every bit mature fibre when the prison theatre cellphone wall of the moisture-swollen fibre represents 50-80% of the circular cross section, every bit young when it represents 30-45% as well as every bit dead when it represents less than 25%.

Immature fiber leads to :

|

| Cotton fiber structure |

- Nepping,

- Loss of yarn strength,

- Varying dye ability,

- High proportion of curt fibres,

- Processing difficulties mainly at the carte du jour

Immature fibre → Dye absorb ↓.

4. Fiber Strength :

Toughness of fibre has a straight upshot on yarn & cloth strength.

Fibre forcefulness ↑→ Yarn & Fabric strength.↑

Very weak cottons tend to rupture during processing both inwards blow room & carding, creating curt fibres & consequently deteriorate yarn forcefulness & uniformity.

The next scale of value is used :

In add-on to usable fibers, cotton wool stock incorporate unusual affair or trash or unusual stuff of diverse kinds :-

Vegetable affair :

4. Fiber Strength :

Toughness of fibre has a straight upshot on yarn & cloth strength.

Fibre forcefulness ↑→ Yarn & Fabric strength.↑

Very weak cottons tend to rupture during processing both inwards blow room & carding, creating curt fibres & consequently deteriorate yarn forcefulness & uniformity.

The next scale of value is used :

- Below to 70% → weak,

- 70% to 74% → fairly strong,

- 75% to 80% → medium strong,

- 81% to 86% → strong,

- 87% to 92% → real strong,

- 93% & higher upward → excellent.

In add-on to usable fibers, cotton wool stock incorporate unusual affair or trash or unusual stuff of diverse kinds :-

Vegetable affair :

- Husk portions

- Seed fragments

- Stem fragments

- Wood fragments.

- Earth

- Sand, dust, coal.

- Metal fragments

- Cloth fragments

- Packing materials.

- Drafting disturbance,

- Yarn breakage,

- Filling upward of carte du jour clothing,

- Contaminated yarn.

Accepted the hit of unusual matters to the Cotton Bale –

- Up to 1.2% → real construct clean

- 1.2% to 2.0% → clean

- 2.0% to 4.0% → medium

- 4.0% to 7.0% → muddied

- 7.0% & higher upward → very dirty.

Colour is peculiarly of import every bit a mensurate on how good a yarn or cloth volition dye or bleach. Instrumental techniques for determining the color of the sample convey solely straight off reached the Industry, HVI mensuration of color provides reasonably accurate results of average reflectance & yellowness inwards a sample.

You tin besides like:

- Cotton Fiber: Cultivation to Production

- Technical Properties of Cotton Fiber

- Chemical Composition of Cotton Fiber

- Structure of Cotton Fiber

- Physical Properties of Cotton Fiber | End Uses of Cotton Fiber

- Production of Cotton Fiber From Field to Mill

- History as well as Introduction of Hybrid Seed Cotton

- Organic Cotton | Production as well as Benefits of Organic Cotton

- Ginning | Cotton Ginning Process | Types of Ginning