Yaa Upshot Of Fiber Properties On Yarn Hairiness Inwards Telephone Spun Yarn

Tuesday, 18 December 2018

Edit

Effect of the Type of Fibers together with Their Properties on Yarn Hairiness on Ring Spun Yarn

S.Sivakumar

Production Manager

Oxford Amalgated PLC, Federal Democratic Republic of Ethiopia

Email: skumars72ss@gmail.com

Production Manager

Oxford Amalgated PLC, Federal Democratic Republic of Ethiopia

Email: skumars72ss@gmail.com

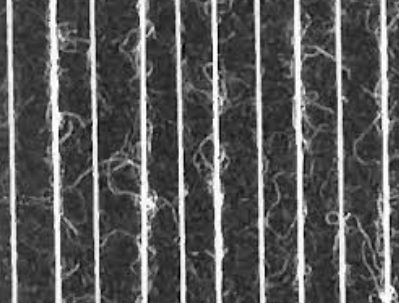

Yarn Hairiness:

Yarn hairiness is the amount of fibers protruding from the yarn trunk measured inwards damage of its length together with release of fibers. Now a days hairiness plays a vital utilization inwards accessing the yarn lineament every bit it heavily influences the lineament of the cloth produced from the spun yarn inwards knitting every bit good every bit weaving. The essential cloth properties of pilling resistance together with abrasion resistance are affected past times the yarn hairiness. Also the surgical operation of Warping machine, Sizing machine, high speed knitting together with high speed weaving machines are besides affected past times the yarn hairiness.

|

| Yarn hairiness |

Hairiness is measured inwards ii methods.

A. Hairiness Index (H): USTER introduced this method of testing. It is the value represents the full length inwards CMs of the protruding fibers inwards 1 CM length of yarn.

B. Hairiness Index (S3): ZWEIGLE counts the release of protruding fibers of unlike lengths separately. S3 value is the amount of the release of fibers of three mm together with longer length of protruding fibers.

Hairiness is widely influenced past times fiber properties, procedure parameters, spindle speed, traveller selection, mechanism conditions, Relative humidity together with amount of twist. But inwards this article nosotros are discussing close the fiber properties. They are,

- Torsional rigidity

- Fiber length

- Fiber fineness

- Short fiber content

- Uniformity

- Fiber cross department / shape

It is the ratio of the torque applied close the fundamental axis of the yarn at 1 goal of the yarn to the resulting torsional angle, when the other goal is held fixed. On other hand, it is the resistance of the textile fiber or yarn against twisting. The torsional rigidity of the cotton fiber fibers are real much depends on their fiber fineness. It is real sensitive to the Relative humidity.

This is the prime number holding which affects the hairiness of yarn. The fibers amongst higher Torsional rigidity convey higher yarn hairiness together with vice versa.

2. Fiber length

The yarn hairiness reduces amongst growth inwards fiber length. The argue is the reduction inwards release of fiber ends protruding from the yarn surface resulting inwards less hairiness. While using longer fibers, the fibers tend to overlap on the yarn surface inwards a improve agency together with thus improve the compactness of yarn which results less hairiness.

3. Fiber fineness

The yarn hairiness is less for finer fiber together with higher for coarser fiber. The torsional rigidity is the most essential holding of the fibers contributes to the formation of hairiness. Generally the finer fiber volition convey less torsional rigidity together with thus the hairiness volition endure less. The coarser fiber has higher torsional rigidity together with higher hairiness inwards yarn. When the yarn delivering to the forepart roller nip together with piece twist insertion, the higher centrifugal strength acting upon the coarser fiber leads to higher hairiness.

4. Short fiber content

SFC has positive correlation amongst the yarn Hairiness. Increase inwards SFC volition growth yarn hairiness together with vice versa. The growth inwards release of protruding ends inwards yarn surface due to shorter fiber length leads to growth the yarn hairiness.

5. Uniformity Ratio

As the growth inwards Uniformity ratio improves the hateful fiber length together with thus this holding having a negative correlation amongst yarn Hairiness.

6. Fiber cross department / Shape

Comparing the circular together with non-circular cross sectional fibers, the yarn hairiness is less amongst the yarn spun amongst circular cross sectional fibers. The compactness of fibers piece using circular cross department fibers is improve than that of other together with thus the hairiness is less amongst circular cross department fibers.

But the impact of twist on hairiness inwards non- circular cross department fibers is improve than circular cross department fibers. Higher the twist volition cut down the Hairiness to to a greater extent than extent inwards non- circular cross sectional fibers.

References

- Influence of fiber length together with denier on properties of polyester cry together with air jet spun yarns. – Influenza A virus subtype H5N1 Basu& K P Chellamani – IJFTR – Vol.25-Sep 2000

- Influence of Polyester fiber shape together with size on the hairiness together with around mechanical properties of yarns. – R K Vashney, V K Kothari & southward Dhanija – IJFTR – Vol.39 –Mar 2014

- The Use of Monte Carlo Techniques to report yarn hairiness for Ring spun yarns. – RMUTP International conference- Textiles & Fashion 2012 – July 2012

- Torsional properties of staple fibre plied yarns – D G Phillips, west B Fraser together with G H thou Van der Heijden – November 2008

- The Rieter Manual of spinning – Vol.1 – Technology of curt staple spinning – Werner Klein