Yaa Compass Of Seam Engineering To Growth The Seam Pull Yesteryear Controlling Dissimilar Parameters (Part-3)

Saturday, 15 December 2018

Edit

Scope of Seam Engineering to Increase the Seam Strength yesteryear Controlling Different Parameters (Part-3)

Authors: MD. Momenur Rahman,

Kazi Mustafijur Rahman,

Rabeya Siddiqua

Atish Dipankar University of Science together with Technology

Dhaka, People's Republic of Bangladesh

Authors: MD. Momenur Rahman,

Kazi Mustafijur Rahman,

Rabeya Siddiqua

Atish Dipankar University of Science together with Technology

Dhaka, People's Republic of Bangladesh

Previous Part

Result Overview

There are diverse parameters of sewing thread including its fiber type, construction, finish, size, ply & TPI, which touching the seam quality.

These parameters volition last hash out next :

Various cloth properties similar Cover factor, GSM, Thickness, Strength, Extensibility etc.

Human Factor:

- From the experimental work, it’s concluded that the usage of thicker threads did non ever give amend forcefulness together with the seam appearance was likewise poor.

- A combination of finer thread amongst moderate forcefulness together with a medium score of stitch density according to cloth weight category provided an effective resultant for both seam appearance together with strength.

- Sewing Thread Size/Ticket Number, GSM, SPI &SPM is the principal considerable signal of the thesis. Change inward those parameters seam forcefulness is changed.

- The usage of depression together with medium stitch density gave amend results inward damage of seam strength.

- In the prediction, thread tensile strength, extensibility together with size were selected in close of the equations.

- Thread properties play an of import usage inward determining the character of seam.

- The equations accept non been tested amongst other types of sewing threads since threads used for this written report are unremarkably used inward the wearing clothing industry.

- Other types of stitches together with seams could last used to run upward the fabrics together with analysis on their seam functioning could last done.

- For this research, entirely unmarried stitching was used; to a greater extent than or less other possible enquiry area is to usage double stitching.

There are diverse parameters of sewing thread including its fiber type, construction, finish, size, ply & TPI, which touching the seam quality.

These parameters volition last hash out next :

- Thread Fiber Type (seam forcefulness highest for 100% spun polyester, average for cotton/polyester blend & lowest for 100% cotton).

- Thread Construction (seam forcefulness highest for inwardness spun yarn; 100% synthetic fiber shows to a greater extent than seam strength).

- Thread Finish (mercerized threads shows to a greater extent than seam forcefulness than whatever soft cotton fiber threads of the same fiber type together with size ).

- Thread Ply (the to a greater extent than the thread ply, the to a greater extent than the seam forcefulness is)

- TPI (the to a greater extent than the TPI, the to a greater extent than the seam forcefulness is).

Effect of Thread size (Ticket Number) on seam forcefulness

Graphical Expression

|

| Data table |

- The numerical facial expression of sewing thread fineness or coarseness is “Ticket number”. It is equal to iii times the metric count of the thread.

- The to a greater extent than the ticket number, the high the seam strength is.

Various cloth properties similar Cover factor, GSM, Thickness, Strength, Extensibility etc.

In the next sections these cloth properties are discussed inward brief:

- Cover Factor (the to a greater extent than the embrace factor, the less the seam forcefulness is, the less the embrace factor, the more the seam forcefulness is).

- Fabric Weight(light cloth shows less seam forcefulness than heavy fabrics).

- Fabric Thickness (the to a greater extent than the cloth thickness, the to a greater extent than the seam)

- Strength is & less seam efficiency)

- Fabric Strength (the to a greater extent than the cloth strength, the to a greater extent than the seam forcefulness is & less seam efficiency)

- Fabric extensibility (the to a greater extent than the cloth extensibility, the to a greater extent than the seam forcefulness is & less seam efficiency).

Effect of GSM on seam forcefulness

Graphical Expression

Related:

Graphical Expression

|

| Data table |

- GSM agency “Gram Per Square Meter”.

- It is the weight of cloth inward gram per i foursquare meter.

- By this nosotros tin compare the fabrics inward unit of measurement expanse which is heavier together with which is lighter.

- In a sure enough point, when GSM increases seam strength increment & over the fourth dimension seam forcefulness decreases though GSM increase.

Graphical Expression

|

| Data table |

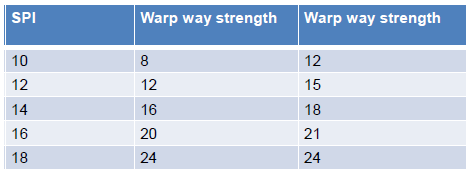

- Stitch density is specified every bit the seat out of stitches per inch (SPI).

- Higher stitches per inch (SPI) agency brusk stitches; together with lower SPI agency long stitches.

- The greater the SPI inward a seam, the greater the seam forcefulness is & the lower the SPI inward a seam, the lower the seam forcefulness is.

Effect of stitch per infinitesimal (SPM) on seam forcefulness

Graphical Expression

Effect of other factors on seam forcefulness Graphical Expression

|

| Data table |

- Modern sewing machine speed tin arrive at upward to 5,500 stitches a minute.

- The fact is that, inward a high speed sewing machine the motility of the sewing needle is higher that generates heat.

- This creates seam impairment occupation that causes of miserable seam efficiency together with appearance inward a garment.

Human Factor:

- If the operator is lacking inward skill, seam problems volition last generated during sewing.

- Excessive or improper treatment together with positioning of the cloth parts during sewing atomic number 82 to seam puckering.

- If the operator is unable to handgrip the sewing machine properly, at that topographic point is a chance of seam impairment due to frequent needle breakage.

- All environmental problems trim the concentration together with science of the operator to work.

- Due to miserable concentration together with reduction of the skill, the operator cannot properly handle the garment parts during stitching.

- High humidity together with temperature likewise reduced the forcefulness of sewing thread during sewing that create miserable seam strength.

- For the analysis of the seam strength, transverse loading was used for this written report where the loading was across the seam together with the resultant of thread forcefulness was analyzed. For hereafter work, the seam forcefulness exam could likewise last done on longitudinal loading where the charge is parallel to the seam.

- The functioning of seam tin likewise last widened for weft together with bias directions of sewing for both seam appearance together with forcefulness analysis. For the electrical flow study, only the warp management of sewn fabrics was analyzed since this is the close common practise inward the industry.

- ü Other types of stitches together with seams could last used to run upward the fabrics together with analysis on their seam functioning could last done. For this research, entirely unmarried stitching was used; to a greater extent than or less other possible enquiry expanse is to usage double stitching.