Now You Know Characterization of Pore Structure in Textiles (Part-3)

Friday, 8 March 2019

Edit

Characterization of Pore Structure in Textiles (Part-3)

Arpita Kothari

M. Tech. Scholar

Department of Textile Technology,

NIT Jalandhar, India

Cell: +91- 7837-696041

Email: geniousarpita@gmail.com

Arpita Kothari

M. Tech. Scholar

Department of Textile Technology,

NIT Jalandhar, India

Cell: +91- 7837-696041

Email: geniousarpita@gmail.com

5. Analysis of experimental data measured from capillary flow porometer:

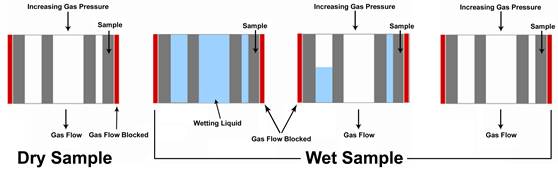

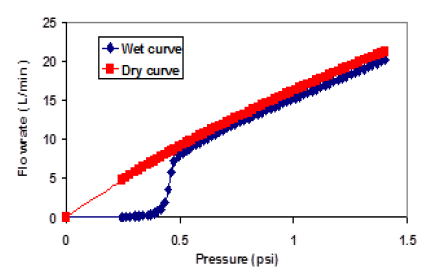

Porometry has the unique ability to measure all the important pore structure characteristics. [4] The differential pressure on dry and wet sample has gradually increased and then gas flow rate measured as a function of diffrential pressure. [1]

|

| Figure 5: Measured gas flow rates in the dry and wet conditions of a sample as a function of differential gas pressure. |

Gas flow rate through the dry sample increases with increase in differential pressure because all the pores in the dry sample are free from the wetting liquid and are open for gas flow. The manner in which the gas flow rate through the dry sample increases with differential pressure can be predicted. [1]

Flow rate depends on

- Pore diameter

- Number of pores

- The inlet pressure , that changes

Initially pores are blocked by liquid, as pressure increase largest pore emptied, further increament causes smallest pore emptied and gas flow started. [1]

Pore Structure Characteristics Measured:

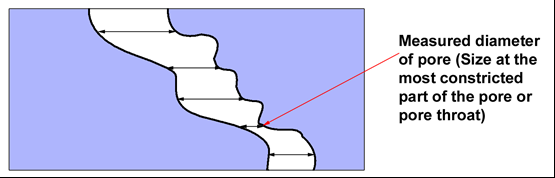

5.1. Throat pore diameter:

The differential pressure required for displacement of liquid at the most constricted part of the pore (pore throat) is the maximum. When this maximum pressure is reached, the gas removes liquid completely from the constricted part of the pore as well as from the rest of the pore beyond the most constricted part and begins to flow through the pore. The porometer detects the increase in flow. Therefore, the differential pressure of the gas at which gas flow through a pore occurs yields the diameter at the most constricted part of that pore. [1].

Pore diameter, D= equivalent cylindrical pore diameter

[dS/dV] pore = [dS/dV] cylindrical pore = 4/D

p = 4 γ cos Ɵ / D

Where,

p = differential gas pressure on wetting liquid in pore

γ = surface tension of wetting liquid

Ɵ = contact angle of the liquid

dV = displaced volume of liquid in the pore

dS = increase of solid/gas surface area due to displacement of liquid.

γ = surface tension of wetting liquid

Ɵ = contact angle of the liquid

dV = displaced volume of liquid in the pore

dS = increase of solid/gas surface area due to displacement of liquid.

|

| Figure 6: Variation of through pore diameter along pore path and the measured diameter of the pore. |

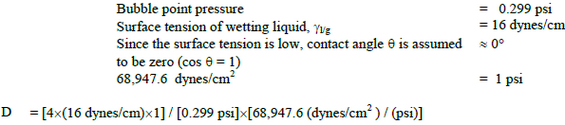

5.2. The Largest Through Pore Throat Diameter (The Bubble Point Pore Diameter):

The largest pore throat diameter is the largest of the most constricted pore diameters of all pores. The differential pressure required to start gas flow through a wet sample is known as the bubble point pressure or simply the bubble point because at this pressure the first air bubbles start forming on the sample. The differential pressure that can empty the largest of the throat diameters of all through pores, initiates gas flow though a wet sample and is the bubble point pressure. [1] Gas flow through a wet sample is zero at the beginning of the wet test, but starts at certain differential pressure, which is the bubble point pressure. The pore diameter computed from bubble point pressure is the bubble point pore diameter.

|

| Figure 7: Bubble point pressure in the plot of flow rate versus differential pressure |

From experimental data (Figure 15):

|

|

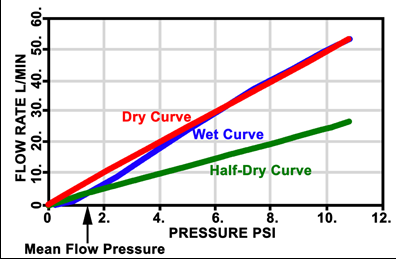

In order to determine the mean flow through pore diameter, half-dry flow needs to be computed from measured dry flow (gas flow through dry sample). Half-dry flow is half of the dry flow at a given differential pressure. The differential pressure at which the wet flow and the half-dry flow are the same is known as the mean flow pressure. The pore diameter calculated from the mean flow pressure is known as the mean flow pore diameter. Mean flow pore diameter is such that half of the flow through a dry sample is through pores having diameter greater than the mean flow pore diameter, and the other half of the flow is through pores having diameter smaller than the mean flow pore diameter. [1]

|

| Figure 8. Dry, wet and half-dry curves for a filter and the mean flow pressure. |

The bubble point pressure gives the largest through pore throat diameter, and the differential pressure at which the wet and dry curves meet gives the smallest pore throat diameter in the sample. These two pore diameters give the pore size range in the sample. [1]