Now You Know Application of Ultrasound in the Preparation of Cotton and Silk Fabric (Part-2)

Friday, 8 March 2019

Edit

Application of Ultrasound in the Preparation of Cotton and Silk Fabric (Part-2)

Utpal Mondal

Govt. College of Engineering and Textile Technology

Berhampore, Murshidabad, India

Email: utpal.khs.gcettb07@gmail.com

Govt. College of Engineering and Textile Technology

Berhampore, Murshidabad, India

Email: utpal.khs.gcettb07@gmail.com

3. Applications

Ultrasound is used in many applications, such as homogenizing, disintegration, sonochemistry, cleaning etc. Even this is used for medical diagnosis and therapy and also as a surgical tool. Now discuss about these in the following.

3.1 Motion sensors and flow measurement:

Ultrasonic sound can be used as motion sensor, i.e. automatic door opener, where an ultrasonic sensor detects a person’s approach and opens the door.

Ultrasonic sensor can control a wide area from a single point. The flow in pipes or open channels can be measured by ultrasonic flow meters, which measure the average velocity of following liquid [5].

3.2 Non-destructive testing:

Ultrasonic testing is a type of non-destructive testing commonly used to find flaws in materials and to measure the thickness of objects. Frequencies of 2 to 10 MHz are common. Lower frequency ultrasound (50–500 kHz) can also be used to inspect less dense materials such as wood, concrete and cement [5].

3.3 Biomedical applications:

Ultrasound also has therapeutic applications, which can be highly beneficial when used with dosage precautions. Relatively high power ultrasound can break up stony deposits or tissue, accelerate the effect of drugs in a targeted area, assist in the measurement of the elastic properties of tissue, and can be used to sort cells or small particles for research [5].

3.4 Ultrasonic range finding:

A common use of ultrasound is in underwater range finding; this use is also called sound navigation and ranging. An ultrasonic pulse is generated in a particular direction. If there is an object in the path of this pulse, part or all of the pulse will be reflected back to the transmitter as an echo and can be detected through the receiver path. By measuring the difference in time between the pulse being transmitted and the echo being received, it is possible to determine the distance [5].

3.5 Ultrasonic Cleaner:

Ultrasonic cleaners, sometimes mistakenly called supersonic cleaners, are used at frequencies from 20 to 40 kHz for jewellery, lenses and other optical parts, watches, dental instruments, surgical instruments, diving regulators and industrial parts. An ultrasonic cleaner works mostly by energy released from the collapse of millions of microscopic cavitations near the dirty surface. The bubbles made by cavitation collapse forming tiny jets directed at the surface [5].

3.6 Sonochemistry:

Ultrasound in the 20–100 kHz range is used in chemistry. The ultrasound does not interact directly with molecules to induce the chemical change, as its typical wavelength is too long compared to the molecules. Instead, the energy causes cavitation which generates extremes of temperature and pressure in the liquid where the reaction happens. Ultrasound also breaks up solids and removes passivating layers of inert material to give a larger surface area for the reaction to occur over. Both of these effects make the reaction faster. In 2008, Atul Kumar reported synthesis of Hantzsch esters and polyhydroquinoline derivatives via multi-component reaction protocol in aqueous micelles using ultrasound [5].

3.7 Ultrasonic welding:

In ultrasonic welding of plastics, high frequency (15kHz to 40kHz ) low amplitude vibration is used to create heat by way of friction between the materials to be joined. The interface of the two parts is specially designed to concentrate the energy for the maximum weld strength [5].

3.8 Ultrasound identification (USID):

The ultrasound identification data is used by IBM's Real-Time Location Service software to not only track and visualize equipment with location accuracy to zone, room or sub-room levels, but to generate alerts and automate responses [6].

3.9 Acoustic microscopy:

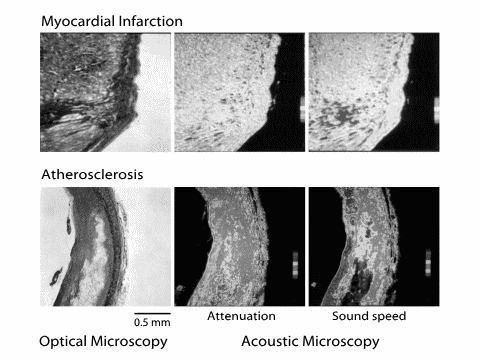

The Acoustic Microscopy method uses a high frequency ultrasound transducer to emit sound waves that are either echoed by or transmitted through a material. The resulting acoustic signature or waveform may be interpreted to determine variations of acoustic impedance within a sample.

3.10 Sonogram of a foetus:

An ultrasound exam is a procedure that uses high-frequency sound waves to scan a woman’s abdomen and pelvic cavity, creating a picture (sonogram) of the baby and placenta. Although the terms ultrasound and sonogram are technically different, they are used interchangeably and reference the same exam.

Ultrasounds may be performed at any point during pregnancy, and the results are seen immediately on a monitor during the procedure. Transvaginal scans may be used early in pregnancy to diagnose potential ectopic or molar pregnancies [8].

3.11 Veterinary medicine:

Various types of treatment can be done using ultrasonic sound. Ultrasound competes with other forms of medical imaging, such as X-ray techniques and magnetic resonance imaging, it has certain desirable features—for example, Doppler motion study—that the other techniques cannot provide. In addition, among the various modern techniques for the imaging of internal organs, ultrasonic devices are by far the least expensive. Ultrasound is also used for treating joint pains and for treating certain types of tumours for which it is desirable to produce localized heating. A very effective use of ultrasound deriving from its nature as a mechanical vibration is the elimination of kidney and bladder stones [9].

3.9 Acoustic microscopy:

The Acoustic Microscopy method uses a high frequency ultrasound transducer to emit sound waves that are either echoed by or transmitted through a material. The resulting acoustic signature or waveform may be interpreted to determine variations of acoustic impedance within a sample.

|

| Figure. 4: Acoustic Microscopy [7] |

An ultrasound exam is a procedure that uses high-frequency sound waves to scan a woman’s abdomen and pelvic cavity, creating a picture (sonogram) of the baby and placenta. Although the terms ultrasound and sonogram are technically different, they are used interchangeably and reference the same exam.

Ultrasounds may be performed at any point during pregnancy, and the results are seen immediately on a monitor during the procedure. Transvaginal scans may be used early in pregnancy to diagnose potential ectopic or molar pregnancies [8].

3.11 Veterinary medicine:

Various types of treatment can be done using ultrasonic sound. Ultrasound competes with other forms of medical imaging, such as X-ray techniques and magnetic resonance imaging, it has certain desirable features—for example, Doppler motion study—that the other techniques cannot provide. In addition, among the various modern techniques for the imaging of internal organs, ultrasonic devices are by far the least expensive. Ultrasound is also used for treating joint pains and for treating certain types of tumours for which it is desirable to produce localized heating. A very effective use of ultrasound deriving from its nature as a mechanical vibration is the elimination of kidney and bladder stones [9].