Now You Know Non-Woven Melt Blown Technology

Sunday, 3 February 2019

Edit

Melt Blown Non-Woven

K V Lokesh

Department Of Textiles

D. K. T. E. Society's Textile & Engineering Institute, Ichalkaranji

Email: lokeshkv.dhtech@gmail.com

K V Lokesh

Department Of Textiles

D. K. T. E. Society's Textile & Engineering Institute, Ichalkaranji

Email: lokeshkv.dhtech@gmail.com

Abstract

Melt blown technology, which has tremendous growth in the last two decades, has its own advantages and drawbacks. There have been many developments mainly in its manufacturing process and in applications. This paper gives a brief report of production process; important parameters which influence this process, structure property relationships, economical aspects and some important applications of melt blown technology.

1. Introduction

Melt blown process was initiated in 1951 by the US Navel Research laboratories in an effort to develop organic microfibres of less than 1µm in diameter. The researchers intended to produce fibers, which were to be used for microdenier filters to collect radioactive particles in the upper atmosphere. This initial research and development work on meltblown processes was continued by an Exxon affiliate in the mid 1960s, and Exxon successfully demonstrated the first melt blowing unit for producing micro denier webs in the early 1970s. Melt-blown micro fibers generally have diameters in the range of 2 to 4 μm, although they may be as small as 0.1 μm and as large as 10-15μm. In this paper a critical review of the various aspects of melt blown non-wovens are addressed [1-3].

2. Melt Blown Process

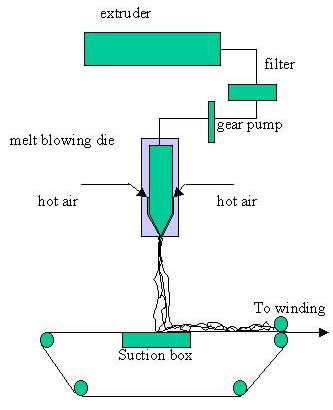

Basic process involved in melt blowing is one-step process in which high-velocity air blows a molten thermoplastic resin from an extruder die tip onto a conveyor or take-up screen to form a fine fibrous and self-bonding web as shown in Figure 1 [4].

|

| Figure 1: Process layout of melt blown systems. |

2.1. Extruder

The polymer pellets which are fed through the hopper feeder supplies pellets to the Archimedean screw, which rotates conveys pellets forward along hot walls of the cylinder between the grooves of the screw. As the polymer moves along the cylinder, it melts due to the heat and frictional force. The screw is divided into feed, transition, and metering zones.

- The feed zone-preheats the polymer pellets

- Transition zone- compresses and homogenizes the melting polymer

- Metering zone-serves to generate maximum pressure for extrusion. The pressure of molten polymer is controlled by the breaker plate with screen pack. It also filters out dirt and infused polymer lumps [5-7].

It delivers melt to the die assembly uniformly and ensures consistent flow of polymer mix under process variations in viscosity, pressure, and temperature.The metering pump typically has two intermeshing and counter-rotating toothed gears, which provides uniform flow to the die nosepiece [8, 9].

2.3 Die Assembly

2.3.1. Feed Distribution:

Feed Distribution in a melt-blown die is more critical than sheeting die for two reasons. Die usually will not have any mechanical adjustments to compensate for variations in polymer flow across the die width, the process is often operated in a temperature range where thermal breakdown of polymers proceeds rapidly [10, 11].It balances both the flow and the residence time across the width of the die. There are 2 types of feed distribution. T-type (tapered and un tapered) and Coat hanger type (widely used due to better balancing of flow and residence time)

2.3.2 Die Nosepiece:

Design and fabrication of the nosepiece decides the web uniformity. The die nosepiece is a hollow and tapered piece of metal having several hundred orifices across the width. The polymer melt is extruded from these holes to form filament strands and hot air is passed along the fibers. Typical die nosepiece has 0.4 mm diameter and orifices spaced at 1 to 4 per mm. There are 2 types of die nosepiece used: capillary type (slots) and drilled hole type (very small holes) [12, 13]. During processing, die assembly is heated section-wise using external heaters to attain desired processing temperatures. Monitoring of the temperatures is necessary to produce uniform webs. Typical die temperatures range from 2l50C to 3400C.

2.3.3 Air Manifolds

The air manifolds supply the high velocity hot air through the slots on to the die nosepiece, which is generated by air compressor. The compressed air is passed through a heat exchange unit to heat the air to desired processing temperatures. Typical air temperatures range from 2300C-3600C at velocities of 0.5 to 0.8% of the speed of sound.

2.4 Web Formation

As soon as the molten polymer is extruded from the die holes, high velocity hot air streams (exiting from the die nosepiece) attenuate the polymer streams to form micro fibers. As the hot air stream containing the micro fibers progresses toward the collector screen, it draws in a large amount of surrounding air (also called secondary air) that cools and solidifies the fibers. The solidified fibers get laid randomly and entangle themselves onto the collecting screen, forming a self-bonded nonwoven web due to the turbulence of air [14].

|

| Figure 2: Melt blown non-woven web. |

2.5 Winding

The melt-blown web is usually wound onto a cardboard core and processed according to the end-use requirement.

2.6 Bonding

Additional bonding over the fiber adhesion and fiber entanglement that occurs at lay down is employed to alter web characteristics. Thermal bonding is the most commonly used technique. The bonding can be either overall (area bonding) or spot (pattern bonding). Bonding is usually used to increase web strength and abrasion resistance. As the bonding level increases, the web becomes stiffer.

2.7 Finishing

Although most nonwovens are considered finished, when they are rolled up at the end of the production line some of the treatments such as calendaring, embossing, and flame retardant treatments can be applied during production.

3. Fibres Suitable for Melt Blowing Technique

- Polypropylene, nylon 6 is easy to process and makes good web

- Nylon 11 melt-blows well into webs that have very unusual leather like feel

- Polypropylene with its low viscosity has a low melting point and is easy to draw into fibers

4. Important Parameters Influencing the Properties of Melt Blown Non-wovens

- Polymer and its throughput

- Die-to-collector distance, and quench environments

- Hole size, die setback, air gap, air angle, web collection type

- Polymer characteristics: molecular weight, melt viscosity, melt strength

- Extruder conditions: temperature, shear, polymer degradation

- Die tip geometry: hole diameter, air gap, die tip position

- Hot air conditions: volume, temperature, velocity

- Polymer conditions: temperature, flow rate, shear rate

- Die conditions: temperature profile, gas flow rate profile, polymer flow rate profile

- Ambient air conditions: temperature, lack of turbulence

- Distance from the die to the forming drum or belt

- Random fiber orientation

- Lower to moderate web strength, deriving strength from mechanical entanglement and frictional forces

- Generally high opacity (having a high cover factor)

- Fiber diameter ranges from 0.5 to 30 μm, but typically from 2-7 μm[6]

- Basis weight ranges from 8-350 g/m2, but typically 20-200 g/m2

- Microfibers provide a high surface area for good insulation and filtration characteristic

- Most melt-blown webs are layered or shingled in structure, the number of layers increases with basis weight

There are 3 major defects that occur in melt-blown

- Roping: It is caused by uncontrolled turbulence in the air-stream and by movement of fibers during and after lay down

- Shot: It is caused by excessively high temperatures or by too low a polymer molecular weight

- Fly: It is caused by too violent blowing conditions

- Melt-blown product is essentially isotropic

- The physical properties will normally also be isotropic. If desired, the fiber orientation in the web can be skewed by the use of selected processing conditions

- Polymer throughput of PP has a noticeable effect on the physical properties of resultant webs

- Density increases with increasing throughput

- If we decrease both breaking strain and the energy required to break that indicates the brittle nature of the web produced at higher throughput

- The average fiber diameter can be controlled by the specific resin employed and the processing conditions selected

- Medical Fabrics: Disposable gown, drape market, sterilization, wrap segment, Sanitary products etc.

- Adsorbents: Sorbents to pick up oil from the surface of water, such as encountered in an accidental oil etc.

- Filtration media: Filter media, cartridge filters, clean room filters and others

- Apparel: Thermal insulation, disposable industrial apparel and substrate for synthetic leather.

- Electronic Specialties: Liner fabric in computer floppy disks, battery separators and as insulation capacitors.

- Miscellaneous Applications: Manufacture of tents, elastomeric nonwoven fabrics etc.

- With respect to energy, the melt-blown process requires more energy (7-8kwh/kg than spun bond)

- Melt-blown processing is more energy-intensive because of compressed hot air is used for fiber attenuation. About 70% of total energy used for hot air, hence it has higher production cost

- Initial capital investment of a melt-blown line is approximately 3-4 times lower than that of spun bond line.

With the current expansion and concern, it cannot be questioned that melt blown is well on its way to becoming one of the major nonwoven technologies. Technical developments are also on the horizon that will increase the scope and utility of this technology. The applications of specialty polymer structures will no qualm offer new nonwoven materials unobtainable by other competitive technologies. The considerable work to modify the blowing step to something more akin to spraying is also going to have an impact on this technology and the products derived from it. So a strong and bright future be forecasted for this technology.

References

- Milligani, M. W., (2001),US Patent 6,247,911

- Matsui, Y., (1998), US Patent 5,728,407

- Spunbonded and meltblown technology hand book (1999), INDA, USA

- Watt, J, M., (1997), US Patent 5,645,057

- Pall, D. B., (1996), US Patent 5,582,907

- Tsai, F. J., (1999), US Patent 5,952,088

- Chenoweth, V. C., (1998) US Patent 5,772,984

- Nonwovens Markets 1996,International Factbook and Directory, Miller Freeman, Inc United News & media San Francisco/USA 1996

- Minto, M. A., (1968), US Patent 5,720,832

- Bodaghi, H., (1999), US Patent 5,993,943

- Nonwovens Handbook (1988), INDA, USA

- www.3M.com

- www.kcnonwovens.com

- Albrecht, W., Fuchs, H., and Kittelmann, W., “ Nonwoven Fabrics”, (2003) Wiley-VCH, Germany.