Now You Know Textile Industry of Pakistan - An Overview

Monday, 21 January 2019

Edit

Textile Industry of Pakistan - An Overview

TEXTILE INDUSTRY OF PAKISTAN

Textile is a term that comes from “texture” which is a Latin word that means “to weave”. A cloth is manufactured by weaving or knitting forms a fabric.

The textile industry is often considered a backbone of the Islamic Republic of Pakistan’s economy. Pakistan’s textile Industry is the fourth Largest Cotton Producer, sixth largest importer of raw cotton and the third largest Consumer.

INTRODUCTION

The textile industry contributes approximately 46percent to the total output or 8.5 percent of the country GDP. In Asia, Pakistan is the eighth largest exporter of textile products providing employment to 38percent of the employer of the country.

OVERVIEW

Pakistan’s textile industry ranks amongest the top in the world.Cotton based textiles contribute over 60% to the total exports, accounts for 46% of the total manufacturing and provide employment to

|

| Pakistan’s textile industry |

HISTORY OF TEXTILE INDUSTRIES

1950:

In 1950 Textile industry was started in our country. PIDC came into being which had the main objective of industrializing the country in major fields.The modern development of the sector started in 1953 with the inauguration of the Valika textile Mill at Karachi.

1960:

In mid-sixties there were about 180units of textiles bleaching, printing and processing units, mostly situated in Karachi and Punjab. New private investment began with a highly protected home market. Newly established mills were based upon imported technologies but there was a lack of technical staff and shortages of capital.

1970:

In 1970-71 there was 113 textile units and the industry had 2,605 thousand spindles and 30 thousand looms.After the separation of East Pakistan Cotton Export Corporation of Pakistan was established which meant that most of the private sector work was taken over by the state. The textile industry suffered heavy losses because the export of cotton was controlled by the CEC.

1980

There was a rapid growth in spinning sector till 1980-81 spinning continued to expand. The eighties brought a relief to the textile industry due to the boom in international market and industry friendly policies of the government.1980.

1990-98:

World demand for good quality, wide width fabrics grew and replacement and a modernization process started. Machinery for producing garments and made-ups was also freed from import duty. As a result, a huge expansion in the spinning sector took place in the first five years of the 1990s.The number of units rose to 440 in1996-97

1999-2008:

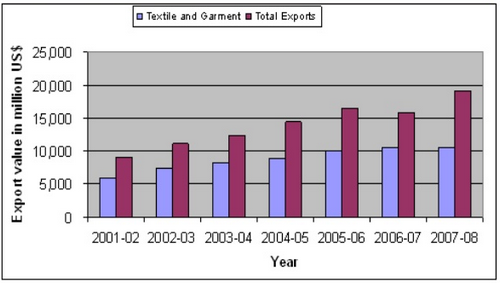

In Textile exports share total export of Pakistan has declined from 67% in 1997to 55% in 2008, as exports of other textile sectors grew Textile exports in 1999 were $5.2billion and rose to become $10.5billion by 2007.

2009:

Textile industry is being hit hard due to ongoing energy crisis, depriving the gas supply to the textile units for three daysa week. Pakistan’s cotton cultivation has declined alsodue to several factors ranging from cultivation of traditional varieties and via traditional methods, poor marketing, and failure in making timely payments to cotton producers.

2010:

Significant changes to the general sales tax (GST) on industrial sector including textiles. (APTMA) had prepared a based report for the federal government in which it has been projected that the textile industry exports would cross over $16 billion compared to its present level of around $8 billion.

2011:

Textile exports stood at $12.5 billion from July 2010 to May 2011.Energy crisis leaves Pakistan textiles in problem

2012:

Pakistan’s $13.8 billion textile industries struggling to survive a critical shortage of energy to run its plants.10 percent of the spinning mills and fabric printing units have shut down, half of the remaining plants are struggling to survive, thousands of textile workers were unemployed, burned tires, and shouted slogans against the government.

2013:

Textile millers and workers were in protest

2014:

New government has done a major achievement which may bring revolution in textile sector

PERFORMANCE CHART:

|

| Performance chart |

Pakistan’s economy relies heavily on its cotton and textile sectors. The cotton-processing and textile industries make up almost half of the country’s manufacturing base, while cotton is Pakistan’s principal industrial crop, supplying critical income to rural households. Altogether, the cotton-textile sectors account for 11 percent of GDP and 60 percent of export receipts.

TEXTILE SECTOR’S CONTRIBUTION TO THE ECONOMY OF PAKISTAN:

According to the economic survey of Pakistan2008-09 the Pakistan textile industry contributes more than 60% to the country total exports, which amounts to around 5.2billion US dollars.• According to the 2012 Economic Survey of Pakistan, issued by the finance ministry, the textile industry itself constituted about 4% of the total size of the economy. TOP BUYERS OF PAKISTANI TEXTILE GOODS:

They are USA, UK, Hong Kong, Japan, Korea, Saudi Arabia, Italy, Turkey, Germany, Norway, France, Canada, Sweden, Australia, etc.

IMPORTANCE OF TEXTILE SECTOR:

In Asia, Pakistan is the 8th largest exporter of textile products. Cotton is the basic Cash crop of Pakistan.• Textile products are one of the essential and basic human requirement next to food.• Pakistan is the 3rd largest exporter of raw cotton

Cheap labor and raw cotton are available. It provides employment to 38% of the work force in the country which amounts to a figure of 15million. However, the proportion of skilled labors very less as compared to that of unskilledlabor. Pakistan is the 2nd largest supplier of cotton yarn with 26%share of the international market.

SECTORS OF TEXTILE INDUSTRY:

- Spinning

- Weaving

- Processing

- Printing

- Garment manufacturing

- Filament yarn manufacturing

Cotton is an economic asset of Pakistan, it is a natural fiber used primarily as a raw material in textile industry. The World cotton production is estimated at118.8 million bales in 2007-2008.

COTTON:

Leading producers of cotton include USA,China, India, Pakistan, Uzbekistan and turkey. Both Punjab and Sindh are the major cotton growing provinces, whereas KPK is not known for growing cotton production.

FIBER:

Cotton was primarily used as a raw material in yarn manufacturing but the growing demand for blended yarn and fabrics has shifted the raw material source towards the manmade or synthetic fiber in Pakistan. Pakistan usage is currently at 74% cotton and26% manmade fiber, whereas the world fiber mix is 45% cotton and 55% non-made fiber.

SPINNING:

Spinning is the process of converting fibers into yarn. The fibers maybe natural fibers such as cotton orman-made fibers such as polyester.Sometimes , the terms spinning is also used for production of manmade yarn (that is not made for fibers). What so ever is the case the final product of spinning is yarn. It consists of:

- Blowing and mixing

- Carding

- Combining

- Drawing

- Simplex

- Ring Spinning

- Cone Winding

Weaving sector is one of the most important textile sub sector. The exports of woolen fabrics and other related woolen made-ups from a major portion of textile exports from Pakistan. Weaving is a process which turns yarns into cloth. The machine used for weaving is the loom. It comprises of Wrapping, Sizing and Weaving

COTTON GINNING SECTOR:

Leading producers of cotton includes USA, china, India, Pakistan, Uzbekistan and Turkey. The current market share of cotton in 56 percent in all fibers. Textile fibers are divided into three basic types according to their sources such as cotton fiber, manmade fiber and wool.

There are 1221 ginning factories in the country. Ginning industry has installed capacity of more than one million bales on a single shift basis and total capacity of around 20million bales on three shift bases.

COTTON SPINNING SECTOR:

Pakistan has the third largest spinning capacity in Asia with a spinning capacity of 5% of the total world and 7.6% of the capacity in Asia. Pakistan growth rate in this sector has been 6.2%per annum.• At present, cotton-spinning sector is comprised of421 textile units (50 composite units and 471spinning units) with 10.1 million spindles and 114thousand rotors in operation with capacity utilization of 89 percent and 60 percent respectively, during July-Mar 2007-08

WEAVING & MADE-UP SECTOR:

There are three different sub-sectors in weaving, Integrated, independent Weaving Units, and Power Loom Units. This sector is producing comparatively low value added Grey Cloth of mostly inferior quality. However, the performance of cloth sector remained far better than last year and charted a growth of 12.6 % during July – March 2007-08.

Textile Value Chain Process:

Cotton value chain starts from Ginning that adds value to it by separating cotton from seed and impurities but Spinning can rightly be called as the first process of the chain that adds value to cotton by converting into a new product i.e. conversion from ginned cotton into cotton yarn. Since spinning is in the beginning of value chain, so all the later value added processes of weaving, knitting, processing, garments and made-ups manufacturing are dependent upon it.

If spinning industry produces sub-standard yarn, its effect goes right across the entire value chain. The spinning sector forms the heart of the textile industry. This sector produces yarn for downstream sectors, namely weaving, processing and knitting. Pakistan is the third largest player in Asia with spinning capacity of 5% of the total world and 7.6% of the capacity in Asia. Pakistan’s growth rate has been 6.2% per annum and there is only Iran amongst the major players.

TEXTILE NEWS:

Textile industry of Pakistan worst hit by powercuts. The energy crisis has forced the textile mills to close their units, especially in Punjab the industry is under severe pressure. ChairmanAPTMA Punjab said ”daily electricity load shedding has increased to 12hours. The Pakistan textile industry contributes more than 60 percent (US $ 9.6 billion) to the country’s total exports. However, currently this industry is facing great decline in its growth rate. The major reasons for this decline can be the global recession, internal security concerns, the high cost of production due to increase in the energy costs etc.”

A spokesman for the All Pakistan Textile Mills Association (APTMA) claimed that 60 to70 per cent of the industry had been affected and was unable to accept export orders coming in from around the globe, as a result of gas load shedding ‘’

PROBLEMS FACED BY TEXTILE INDUSTRY:

- Lack of Research and Development in Cotton Sector

- Lack of Modernize equipment

- Finance bill to burden industry further

- Increasing cost of production

- Internal issues pose a Larger Threat for Pakistan’s Textile Industry

- Effect of inflation

- Energy crisis

- Electricity crisis

- Gas shortage

- Tight monetarypolicy

- Removal of subsidy on textile sector

- Lack of new investment

- Raw material prices

- Export performance of textile sector

All Pakistan Textile Mills Association (APTMA) is the chief organization that determines the rules and regulations in the Pakistan textile industry. APTMA is the premier national trade association of the textile spinning, weaving and composite mills. APTMA represents 391 textile mills out of which309 are spinning, 45 weaving and 37 composite units

HUMAN RESOURCE:

The textile sector employs 45% of overall labor force, with 38% of the manufacturing Workers employed under textile sector. Pakistan has the advantage of cheaper labor as compared to its competitors, but unfortunately thelabor productivity is very low. There are hardly any training programs to develop the skills of labor hence, the craftsmen entirely depend upon their inherited skills with no advancement and movement towards technical knowledge.

CLIMATIC CONDITION:

Although Pakistan has the ideal climatic conditions for the growth of cotton providing a factor advantage to the textile industry, but it is also quite vulnerable to pesticides that can lower the yield per hector.ØThe textile sector is largely dependent on the supply of raw material of the agricultural sector and hence whatever happens to the agricultural sector like floods will adversely affect the textile industry rendering it even more vulnerable to environmental conditions.

TRAINING:

Limited availability of trained technical staff to maintain and run machinery at full efficiency is a constraint upon the developmentof Pakistan’s textile industry. This shortfall is partly due to a lack of technical education facilities. Some of the developments in the textile industry include: Advances in ring spinning, computerized dyeing and finishing, computer-aided designing , manufacturing and developing retailing links hence, all these demand new and greater skills and Pakistan lacks it.

EDUCATION:

Education is essential for the development of the textile industry. Even if the basic factors are present, unless value-addition is not done on them, they will not be productive enough. Even if there is not enough production a country could still manage through research and development. A recent survey shows technical manpower requirement is 12,750 graduates whereas total number of technical personnel available up to 2003 was approx.7, 950, so there is a shortage of 4,800 graduates in textile science.

ADVANTAGE:

The advantage of cheap labor as compared to its competitors, but unfortunatelythe labor productivity is very low.

DISADVANTAGE:

There are hardly any training programs to develop on the skills of these labors and the craftsmen depend upon their inherited skills with no advancement.

STRENGTHS:

- Self-reliance

- Manufacturing flexibility

- Abundance of raw material production

- Design expertise

- Availability of cheap labor

- Growing economy and domestic market

- Progressive reforms

- Highly fragmented sector

- High dependence on cotton

- Lower productivity

- Declining mill segment

- Technological obsolescence

- Non‐participants in trade agreement

Developed countries are using the technology of biotechnology and genetic engineering to increase the quality and quantity of their cotton production. In Pakistan, there is very some research done on small scale by private companies. Practically no efforts are being made by the APTMA in theR&D of the textile industry to enhance the quality of its products.

- Highly fragmented sector

- High dependence on cotton

- Lower productivity

- Declining mill segment

- Technological obsolescence

- Non‐participants in trade agreements

- Poor quality standards

THREATS:

1. New competitors

Pakistan are facing new competitors in textile sector such as Bangladesh, Vietnam and Turkey. Though we cannot avoid competition but we can always stay ahead of them by reforming our strategies and educating our entrepreneurs so as to move one step forward in every aspect.

2. Phasing out of quota system

As the quota system is ruled out by WTO, there is a threat by the Chinese and Indian manufacturer to gain most of the market share. We have high costs, low labor productivity and inefficient production processes.

3. Fashion life cycle

Fashion changes day by day these days. Media has so much penetrated in our daily lives that we easily adapt ourselves as it wants us to. This has resulted in shortening the fashion lifecycle thus increasing the fashion risk. Now the buyer does not want to wait long for his consignment because he is insecure that by the time it will reach to him he will lost its demand due to change in fashion. Therefore, they prefer to buy from neighboring countries even at higher cost to get their products instantly rather than to wait weeks or months for their consignments to reach them.

Stiff competition from developing countries especially China and India, Pricing pressure, Locational disadvantage, International labor and environmental laws.

ENVIRONMENTAL ISSUES

Textile industry is associated with some environmental issues some of them are:

- Large volumes of water

- Usage of complex chemicals

- Discharge of untreated effluent

- Water Pollution,

- Air Pollution.

- Labors concern.

- Remedy though Foreign Direct Investment (FDI)

- Image Building of Pakistan to attract Foreign Direct Investment (FDI)

- Focus on Value Addition

- Technology Up-gradation & Capacity Building

- Human Resources Development

- Subsidy Removal should be taken a back

- Interest Rate should be Low in order to survive

- Electricity & Gas Tariff

- Removal of Energy Crisis

- Exploration of new Export Markets

- Reducing the cost of doing Business in Pakistan

- Needs for Improving Textile Production

- Improvement in productivity

- Awareness of International Quality Standards

- Introducing concept of on the job-training

- Introducing efficient management techniques

Textile industry is the backbone of the Pakistan’s economy. The textile industry of Pakistan plays an important role in earning foreign exchange, providing employment to the country. Pakistan’s textile industry is going through one of the toughest periods in decades. Our textile sector needs to capitalize on the new emerging opportunities by adhering to global best practices, adapting rapidly changing technologies, better supply chain management while trying to reach global value chains.