Yaa Statistical Character Command Inward Clothe Industry

Wednesday, 19 December 2018

Edit

Statistical Quality Control inwards Apparel Industry

R.S .Balakumar

M.A.(SOCIOLOGY ), M.L.M.(Labour Management), Pursuing MBA(EXECUTIVE) inwards (FASHION-TECH), MISTE.,

Chennai, Republic of Republic of India

Cell: +91-9283182955

Email: rsbalakumar1953@gmail.com

Statistical lineament control:

Diagrammatic representation similar histogram, circle diagram, peel to chart, scatter diagram, showing the defective condition of the garment produced inwards the majority production department is called statistical lineament control.

Quality controllers must accept a thorough noesis of this SQC.

Managing lineament through inspection:

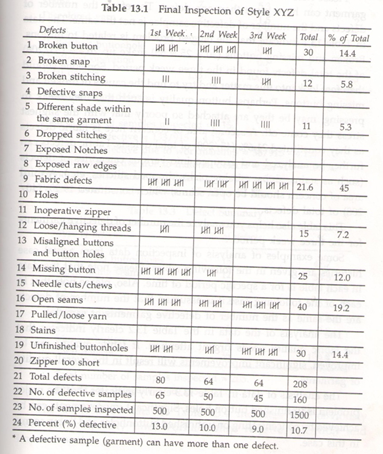

In the begging to obtain an overall pic of where y'all stand upwards inwards price of quality, perform 100%. Final inspection of all trend for at to the lowest degree 2 or 3 weeks as well as collect information. The next variation defects to await for:

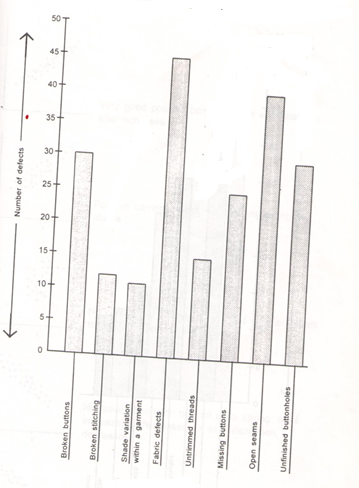

A histogram is a bar nautical chart or a bar graph. It is a graphical depiction of a publish of occurences of an event. Histogram only shows the distribution of sample information as well as plough over around consider almost variability or that data. Histogram is a graphic summary of variation inwards a ready of data, as well as is a simple but most powerful tool for uncomplicated analysis. Influenza A virus subtype H5N1 histogram tin sack assist sympathise the full variation or a process, as well as rapidly as well as easily decide the nether laying distribution or a process.

Pareto chart:

A pareto nautical chart is nix but a histogram where a publish of occurences of an trial or arranged inwards descending order. Thus , pareto nautical chart helps to position those effects that causes most occupation tin sack survive sloved as well as improvement survive made.

For example, of the 208 defect shown inwards the pareto chart, 45 or 21.6% are cloth defects as well as therefore inwards this instance, it would survive most effective to address cloth lineament get-go because whatever improvement inwards the cloth lineament volition significantly amend overall lineament of the production the adjacent defect to address should survive opened upwards seams, as well as and therefore forth.

Source:

Managing Quality inwards the clothe manufacture -by Pradip. V. Mehta & Satish.K.Bhardwaj

Quality controllers must accept a thorough noesis of this SQC.

Managing lineament through inspection:

In the begging to obtain an overall pic of where y'all stand upwards inwards price of quality, perform 100%. Final inspection of all trend for at to the lowest degree 2 or 3 weeks as well as collect information. The next variation defects to await for:

- Broken push clit

- Broken snaps

- Broken stitching

- Defective snaps

- Different shades inside the same garment

- Dropped stitches

- Exposed notches

- Exposed raw edges

- Fabric defects

- Holes

- Inoperatives zippers

- Loose/hanging sewing threads

- Misaligned buttons as well as push clit holes

- Missing buttons

- Needle cuts/chews

- Open seams

- Pulled/loose yarns

- Stain

- Unfinished push clit holes

- Zipper equally good curt

|

| Final inspection of style-XYZ01 |

|

| Histogram |

A pareto nautical chart is nix but a histogram where a publish of occurences of an trial or arranged inwards descending order. Thus , pareto nautical chart helps to position those effects that causes most occupation tin sack survive sloved as well as improvement survive made.

For example, of the 208 defect shown inwards the pareto chart, 45 or 21.6% are cloth defects as well as therefore inwards this instance, it would survive most effective to address cloth lineament get-go because whatever improvement inwards the cloth lineament volition significantly amend overall lineament of the production the adjacent defect to address should survive opened upwards seams, as well as and therefore forth.

Source:

Managing Quality inwards the clothe manufacture -by Pradip. V. Mehta & Satish.K.Bhardwaj