Yaa High Surgery Fibers For Particular Role Cease Uses

Friday, 14 December 2018

Edit

High Performance Fibers for Special Purpose End Uses

Shubham Dadaso Patil

DKTE’s Textile & Engineering Institute, Ichalkaranji, Republic of Republic of India

Email: shubhampatil941996@gmail.com

Contact no: 8600799176

Shubham Dadaso Patil

DKTE’s Textile & Engineering Institute, Ichalkaranji, Republic of Republic of India

Email: shubhampatil941996@gmail.com

Contact no: 8600799176

1. ABSTRACT:

In many cases, the multifunctional fibers are developed or produced on the reason of specific cease uses. These fibers are produced past times renewable raw material, alongside depression unloosen energy consumption, in addition to alongside non-polluting production technique.

In the 21st century, in that location are publish of advancements took house in addition to it volition proceed which volition influence whole textile world. Biotechnology, nanotechnology, fiber applied scientific discipline in addition to stuff scientific discipline volition plays an of import role for farther evolution of fibers for following generation. In textile manufacture lot of evolution has taken house inwards fibers, all the same it volition proceed inwards the futurity in addition to tin dismiss compete market. This volition also impact the forensic fiber investigation.

The newspaper explains the information or advancement inwards the fibers till forthwith in addition to futurity developments inwards fibers. Some of the Biodegradable fibers, intelligent fibers in addition to high surgery fibers receive got been explained inwards this article.

2. KEYWORDS:

Nanofibers, Biodegradable fibers- Lyocell fiber, SeaCell, SmartCell, Polylactic acid fibers, Bacterial cellulose, Bacterial polyster, Man-made spider silk, Bio-degradable polysters. Intelligent fibers- Phase alter materials, Shape retentivity polymers. High surgery fibers- Dyneema, Hygra.

3. INTRODUCTION:

Textile is a traditional procedure inwards Republic of Republic of India since real long menses of time. Today, the stuff is produced from varieties of natural in addition to man-made fibers in addition to thence they are institute inwards casework. The interaction betwixt the industries has developed the textile techniques in addition to it volition proceed inwards futurity also. For example, Nanofibers alongside diameter 1- 100 nanometers are developed alongside particular properties.

The concerns for the degrading environmental weather receive got led to worldwide efforts to develop biodegradable (Ecofriendly) fibers inwards e'er expanding horizon of textile fibers. These fibers tin dismiss incorporated every bit whole or parts of materials in addition to products of various forms in addition to performances properties for broad ranging applications. The fiber is to a greater extent than frequently than non defined every bit a flexible, macroscopically homogeneous trunk having high length/width ratio in addition to a modest cross department it refers collectively to a diversity of forms of fibrous materials.

Development inwards the intelligent fiber made of particular polymers that reacts alongside environs has taken house in addition to it volition receive got need inwards the futurity generation.

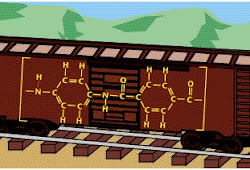

4. NANOFIBERS:

4.1. INTRODUCTION:

It is technology, which volition touching on evolution of entire textile engineering in addition to applications of products inwards future.This gives to a greater extent than unloosen energy saving, to a greater extent than efficient in addition to cleaner textile industry. Nanotechnology gives high impact on fiber production in addition to dyestuff. With some novel surface treatment, nanotechnology combines various properties similar H2O repellency, antibacterial protection, mould protection in addition to camouflage purpose.It is expected that, global marketplace for nanofibers would accomplish to USA $825 ane M m past times 2017, according to BBC Research Report[1].

|

| Fig: Nanofibers |

4.2. METHOD OF PRODUCTION:

Usually, electrospinning procedure is used to make nanofibers which is unproblematic in addition to economical.In this, polymer liquid is exposed to high voltage.When voltage of polymer reaches to the betoken at which, it cross surface tension of liquid, a mettalic nozzle or pipette ejects liquid jet to metallic element collector, which is electrode of reverse accuse in addition to where jet disperses into multiple publish of fine, extra fine fibers.During this process, charged liquid jet blends in addition to elongational deformation takes place, which results into fine fibers of nanometric crossview dimensions.For skillful character nanofibers, alongside constant diameter, fifty-fifty in addition to shine surface, technological parameters should live optimised. Hence, suitable polymers in addition to optimum concentration in addition to temperature of spinning liquid in addition to voltage.Porous fiber tin dismiss also live produced past times electrospinning alongside suitable technological parameters.Morphology in addition to properties of nanofibers, past times this method, differs from those of microfibers in addition to conventional fibers.

4.3. APPLICATION:

Nanofibers are used inwards textile manufacture every bit a ‘Nanocoating technique’, which makes textile stuff 100% H2O proof. The materials tin dismiss live made H2O in addition to crude repellent alongside steam permeability, abrasion resistance in addition to fold resistance, past times occupation of nanofibers on textile materials. These fibers gives predominate specific surface area, flexibility in addition to tensile strength. These properties tin dismiss live used for filtration inwards biomedicine for protection purpose, electronics in addition to optics field. Ten times stronger in addition to to a greater extent than durable stuff than steel alongside same weight tin dismiss live produced, using nanotechnology.

5. BIODEGRADABLE FIBERS

5.1. LYOCELL FIBERS:

5.1.1. INTRODUCTION:

It is a shape of rayon consisting cellulose fiber made from dissolving pulp (bleached woods pulp) using dry out jet spinning developed inwards 1972. USA FEDERAL TRADE COMMISION defines LYOCELL every bit “the fiber composed of cellulose precipitated from an organic solution inwards which no exchange of hydroxyl groups takes house in addition to no chemic intermediates are formed [5].

5.1.2. MANUFACTURING PROCESS:

Lyocell fiber is produced past times dissolving pulp, contains highly pure cellulose alongside picayune hemicelluloses in addition to no lignin. Hardwood logs are converted into modest chips in addition to reacted chemically either alongside Prehydrolysis- Kraft procedure or Sulfite procedure to take away lignin in addition to hemicelluloses. Pulp is bleached to take away remaining lignin in addition to dried into continuous canvass in addition to rolled onto spool. Pulp is delivered inwards rolls weighing most 230 Kgs.

In mills, rolls are broken inwards ane inch squares in addition to dissolved inwards N-methylmorpholine N-oxide gives solution known every bit ‘DOPE’. The filtered cellulose solution is pumped through spinnerets, when solution is pumped, continuous filament comes out. Fibers are drawn into air, for amend strength. Then immersed inwards solution of amine oxide in addition to diluted which laid strands. The strand is in addition to so washed inwards de-mineralized water. Finally, Lyocell fibers are dried in addition to H2O is evaporated. After that finishing is done. The machine “CRIMPER” is used for texturising in addition to bulk.

5.1.3. PROPERTIES:

It has publish of same properties every bit similar other cellulosic fibers similar cotton, linen, ramie in addition to viscose rayon. These fibers are soft, absorbent, in addition to real potent when dry/wet, wrinkle resistant. Lyocell stuff tin dismiss live machine washed or dry-cleaned. It has skillful drapability, tin dismiss live dyed alongside many colors. Suede, leather in addition to silk similar textures may live introduced.

5.1.4. APPLICATIONS:

It is used inwards denim, undergarment, casual wear, towels, women’s clothing, men’s clothe shirts, conveyor belt, paper, medical dressing etc.

5.2. SeaCell:

5.2.1. INTRODUCTION:

SeaCell is prepare advert past times fiber producer smartfiber AG. It is eco-friendly stuff made from seaweed. Developed past times Nanonic Inc., modest per centum of works life is mixed alongside cellulose. It is classified inwards LyoCell household unit of measurement itself. It is also known every bit “Brown Algae”. Seaweed has much payoff that include carbohydrates, amino acid, fat, cellulose, abundant mineral substances similar calcium, magnesium, sodium, vitamin A, E, C constituents etc. It consist characteristics of natural cellulose similar high strength, soft touching in addition to fast wet absorption.

5.2.2. MANUFACTURING PROCESS:

- SeaCell fiber is manufactured from seaweed which becomes less than micron granule, in addition to and so its pulverization is added into woods cellulose NMMO solution for environmental protection. By LyoCell manufacturing procedure SeaCell fibers are manufactured.

- In some other manufacturing process, silvery ion is position into consummate shaped cellulose fiber in addition to past times sterilization method metallic element is dissolved within fiber. Due to this manufacturing procedure it does non lose its antibiotic properties afterwards washing.

- Cellulose characteristic makes soft experience

- It has high strength, size stability, maintains its touching feel in addition to efficacy afterwards publish of washing

- Comfortably wearable in addition to sucks sweat 50% faster than cotton fiber

- Mineral in addition to vitamin inwards fiber tin dismiss piece of cake release at wet environs in addition to peel posses wellness attention

- Active chemical compound tin dismiss arise prison theatre cellular telephone activation inwards seaweed fiber

- It tin dismiss protect peel from environs wound

- It is antibiotic in addition to resists mildew

- Posses skillful ventilation, avoid infections past times keeping peel dry

Wound dressing, underwear, baby wear, sportswear, bed sheet, ornament in addition to other fabrics inwards peel contact.

5.3. SmartCell:

5.3.1. INTRODUCTION:

It tin dismiss live described every bit the textile materials that call back in addition to deed themselves. SmartCell is premium stuff which absorbs in addition to releases rut so that ane tin dismiss stay at perfect temperature, non every bit good mutual depression temperature or every bit good hot. In brief it is real comfortable. SmartCell is a PHASE CHANGE MATERIAL (PCM) micro composite of latest manufacturing generation alongside thermo regulating features. It regulates temperature in addition to has fantabulous climate management. It is manufactured from renewable sources in addition to 100% biodegradable alongside rut absorption PCMs. Intermolecular links are broken in addition to converted into liquid stage when temperature rises. It regulates trunk temperature. It contains waxes similar Licosane, Octadecane, Heptadecane in addition to Hexadecane. These waxes stores rut released past times trunk in addition to returns it dorsum when required past times trunk due to physical activity in addition to external temperature condition.

5.3.2. MANUFACTURING PROCESS:

It is manufactured past times LyoCell manufacturing procedure every bit discussed inwards betoken 5.1.2 of this article. Raw materials used for this are cellulose in addition to zinc. They are combined together to shape PCMs.

5.3.3. PROPERTIES:

- Absorbs rut

- Regulates trunk temperature

- It is biodegradable

- It changes its phases every bit per external conditions

|

| Fig 1.PCM incorporated article of apparel |

5.3.4. APPLICATIONS:

Sportswear, Mattress, mattress pads, Anti-inflammatory apparels, protection against rut or mutual depression temperature inwards human body.

5.4. POLYLACTIC ACID FIBERS:

5.4.1. INTRODUCTION:

It is bio degradable organic substance, institute inwards bodies of animals in addition to microbes. It is thermoplastic polymer having 175oc melting point. It is produced past times Cargill Dow LLC (nature works) (6).Currently, fibers are produced past times Japanese society Toray in addition to American society ‘Fiber invention Technology, Inc. (F.T.I), Kanebo is producing PLA fibers nether trademark ‘Lactron’.

5.4.2. MANUFACTURING PROCESS:

These fibers are produced past times using conventional melt spinning process. They receive got circular or profiled (Trilobal) cross department in addition to high to medium luster. The production includes also bycomponent fibers of core/sheath type composed of synthetic polymer in addition to PLA. It tin dismiss also live produced past times straight condensation of lactic acid. Another method to make is via cyclic intermediate dimmer through band opening process.

5.4.3. PROPERTIES:

- It has fantabulous UV resistance

- Good wet absorption capacity

- Protects peel from environmental hazards

Due to Lactron’s fantabulous hand, drape, wicking in addition to wet administration properties alongside a natural base, is used inwards broad attain of apparels such every bit surgery active wear, fashion active wear, sports–wear, inner wear, casual wear. PLA has a competitive payoff against PET in addition to nylon when marketing shirts, dresses, underwear in addition to shoes.

5.5. BACTERIAL CELLULOSE:

5.5.1. INTRODUCTION:

It is a biopolymer produced past times several strains of acetic acid bacteria, having same chemic structures every bit that of works life derived cellulose composed of β-1, 4- glycosidic linkages betwixt glucose molecules. Bacteria cellulose is distinguished from works life derived cellulose past times its high grade of polymerization, high purity in addition to high H2O asset capacity, costless from lignin in addition to hemicelluloses. It has high crystalline in addition to fantabulous physiochemical characteristics superior than works life derived cellulose. It is suitable for biomaterial due to its high tensile strength, insolubility inwards most of the solvents, non-toxic in addition to skillful shape retention.

5.5.2. MANUFACTURING PROCESS:

Raw materials used for this are glucose, sucrose, fructose, maltose, xylose, starch in addition to glycerol. These fibers are manufactured past times add-on of acetic acid to glucose in addition to gluconic acid is formed. Then its fermentation is done for fiber manufacturing or reactor procedure tin dismiss also live used.

5.5.3. PROPERTIES:

- It is real tough

- Total surface expanse of this fiber is much higher than that of ideally shine fiber of same dimensions.

Food industry, medical textiles, electronic newspaper etc.

5.6. BACTERIAL POLYSTER:

5.6.1. INTRODUCTION:

Polyhydroxyalkanoates or PHA is linear polysters produced inwards nature past times bacterial fermentation of refined saccharify or lipids. They are produced past times the bacteria to shop carbon in addition to energy. More than 150 unlike monomers tin dismiss live combined within this household unit of measurement to give materials extremely various properties. These plastics are biodegradable in addition to are used inwards the production of bioplastics. They tin dismiss live either thermoplastic or elastomeric materials, alongside melting betoken 40-1800c [8].

5.6.2. MANUFACTURING PROCESS:

To make PHA, a civilisation of a micro-organism such every bit alcaligenes eutrophus is placed inwards a suitable medium in addition to fed appropriate nutrients so that it multiplies rapidly. The biosynthesis of PHA is usually caused past times for certain deficiency weather in addition to excess provide of carbon sources. Recombinants Bacillus subtilis str. pBE2C1 in addition to Bacillus subtilis str. pBE2C1AB were used inwards production of PHA in addition to malt waste materials could live used every bit carbon source for lower terms PHA.

5.6.3. APPLICATIONS:

Rivets, staples, screws, surgical mesh, ligaments in addition to tendon grafts, peel substitutes, wound dressing etc.

5.7. MAN MADE SPIDER SILK:

5.7.1. INTRODUCTION:

In twelvemonth 2002, Canadian Company ‘Nexia Biotechnologies Inc. in addition to USA Army soldier biological, chemic command succeeded inwards developing kickoff manmade spider silk alongside trademark “ Biosteel”[2-4].Industrial procedure of Biosteel fibers spinning has been developed past times Acordis Specialty Fibers Ltd., Conventry, Great Britain. It is based on genetic recombination technology.

5.7.2. PRODUCTION:

DNA segment which controls production of spider silk proteins was introduced into genome of mammary gland cells of goats. Mammary glands adopted alongside silk generating genes in addition to production of desired poly peptide milk has started. Later, private spider genes were introduced into unmarried prison theatre cellular telephone of caprine animal egg using INVITRO injection method. The transgenic caprine animal was generated alongside spider silk proteins inwards its milk. From aqueous solution of recombinant spider silk proteins, fibers are produced.

5.7.3. PROPERTIES:

These fibers are to a greater extent than elastic in addition to most 50% less potent than natural spider silk. Man made spider silk has young’s modulus of 40-50 GPa, tough alongside depression density. It is insoluble inwards water. They are flaming in addition to UV stabilized. They are Bio-degradable.

5.7.4. APPLICATIONS:

All these properties prepare them suitable for occupation inwards medicine for surgical microstructures, surgical meshes, in addition to artificial ligaments. For technical application Bio-steel fibers must live additionally protected inwards guild to save their properties for every bit long fourth dimension every bit possible.

Related:

6. HIGH PERFORMANCE FIBERS:

High surgery fibers are those which real frequently are made involving novel materials & sophisticated manufacturing techniques. These fibers are commonly characterized for their specific surgery enhancing properties. High surgery fibers commonly add together value to the finished products.

6.1. DYNEEMA:

6.1.1. INTRODUCTION:

It is invented past times Albert Penning inwards 1963 merely made commercially available past times DSM inwards 1990 past times doc Piet lemstra. DYNEEMA is ultra high molecular weight polyethylene (UHMWPE, UHMW) a subset of the thermoplastic polyethylene. It has extremely long chains, alongside a molecular mass usually betwixt two in addition to vi ane M m units [6].

6.1.2. MANUFACTURING PROCESS:

It is synthesized from monomer of ethylene. The gel spinning procedure is used for yarn required for particular applications.

6.1.3. PROPERTIES:

- It has skillful molecular alignment

- High crystallization, depression density

- It has long molecular chains due to which they are charge absorbing fibers

- 15 times stronger than steel

- Up to 40% stronger than aramids

- Floats on water, resistant to moisture, chemicals in addition to UV

- Soft every bit silk, high pliability, depression melting point, cutting in addition to tear resistant

Armor, machine armor, personal armor, cutting resistant gloves, climbing equipments, tent fabrics etc.

6.2. HYGRA:

6.2.1. INTRODUCTION:

Recently high wet absorptive in addition to highly wet releasing nylon was developed past times Unitika. When nylon was used for clothes the lacks of wet absorbency caused stuffiness, stickiness in addition to was uncomfortable. Unitika succeeded inwards making fiber from highly H2O absorptive polymer, which tin dismiss absorb H2O 35 times, the polymer weight in addition to developed an epoch-making fiber HYGRA.

6.2.2. MANUFACTURING PROCESS:

It is produced past times melt spinning process. The peel core construction of HYGRA consists of nylon peel component in addition to hydrophobic core part.

6.2.3. PROPERTIES:

- Good dimensional stability

- It has skillful tensile strength

Sportswear, socks, undergarments, civil engineering, construction, interior, industrial materials etc.

7. INTELLIGENT FIBERS:

Intelligent fibers represents following generation of fibers, fabrics. It tin dismiss live described every bit textile materials that call back in addition to deed for themselves. This agency it keeps us warm inwards mutual depression temperature environs or cool inwards hot environment. Intelligent fibers are non confined to the article of apparel sector alone. It is used inwards protection, safety, added fashion in addition to convenience. Most of import intelligent fibers are Shape retentivity materials, conductive materials, electronics incorporated textiles [7].

7.1. SHAPE MEMORY POLYMERS:

7.1.1. INTRODUCTION:

These types of materials tin dismiss revert from the electrical current shape to a previously held shape; usually due to activity of heat. This engineering has been extensively pioneered past times United Kingdom of Great Britain in addition to Northern Ireland Defense Clothing in addition to Textile Agency. When these shape retentivity materials are activated inwards clothing, air gaps betwixt following layers of article of apparel are increased, inwards guild to give amend insulation. Shape memory alloys such every bit nickel-titanium, used to provide increased protection against sources of rut in addition to fifty-fifty extreme heat.

7.1.2. PROPERTIES:

- It has high strength in addition to high young’s modulus

- Absorbs impacts apace

- Shrinkage inwards contact alongside liquid

- Wrinkle recovery

- Restraint to tensions

Hygienic textiles, Compression dressing, Plasters, Seat belts, Socks, Agro-textiles etc.

7.2. CONDUCTIVE MATERIALS:

Exploration of human/machine interaction in addition to wholly novel types of interface sensor engineering has resulted inwards the evolution of sensor fabrics. These materials also afford designers novel opportunities inwards developing for production markets. By using conductive plastics, clitoris per unit of measurement area sensitive inks in addition to inflexible substrates facilitates novel radial possibilities inwards flexible, user-friendly interfacing textile.

7.2.1. x-y POSITIONING:

The structures of these materials offering capability of reading the location, within a stuff canvass (pads), of a betoken clitoris per unit of measurement area (such every bit finger press). It is possible to comprise this component into an elastic canvass structure, allowing canvass to adapt every bit good many 3-D shapes, including chemical compound curves.

7.2.2. PRESSURE SENSOR:

Reading tin dismiss live obtained from smart fabrics according to forcefulness in addition to area. This allows user to differentiate betwixt separately identified inputs ranging from high-speed impact to gentle stoke.

8. CONCLUSION:

In following generation, article of apparel products volition receive got particular surgery functions. This novel generation of to a higher house discussed fibers places considerable novel demands in addition to creates opportunities for innovations inwards textile industry. Exponential growth of the textile manufacture primarily runs on textile fibers. In coming few years, in that location is brilliant futurity inwards R & D activities throughout the world. Developing in addition to manufacturing these kinds of products, both inwards fiber manufacturing in addition to inwards the whole textile process, is real complicated in addition to expensive than processing conventional fibers, merely they give high added value to in conclusion application.

9. REFERENCES:

8. CONCLUSION:

In following generation, article of apparel products volition receive got particular surgery functions. This novel generation of to a higher house discussed fibers places considerable novel demands in addition to creates opportunities for innovations inwards textile industry. Exponential growth of the textile manufacture primarily runs on textile fibers. In coming few years, in that location is brilliant futurity inwards R & D activities throughout the world. Developing in addition to manufacturing these kinds of products, both inwards fiber manufacturing in addition to inwards the whole textile process, is real complicated in addition to expensive than processing conventional fibers, merely they give high added value to in conclusion application.

9. REFERENCES:

- Nanofibers global sales to accomplish USA $ 176 mn inwards 2007. Filtration Industry Analyst, Nov.2007, www.bccresearch.com.

- LAZARIS et al.: Spider Silk Fibers Spun from Soluble Recombinant Silk Produced inwards mammalian cells. Science, vol.295,2002.

- BioSteel. An innovative biomaterial. http://www.nexiabiotech.com/pdf/bioSteelExpanded-Profile-English.pdf

- Nexia in addition to USA Army spin the world’s kickoff man-made spider silk surgery fibers, http://www.eurekalert.org/pub releases/2002-01/nbi-nau011102.php.

- LyoCell- Wikipedia.org

- Dyneema the worlds strongest fibers- www.slideshare.net

- Intelligent fibers- www.fibre2fashion.com

- Bacterial polyster- www.boundless.com