Yaa Handling Of Cotton Fiber Fiber Amongst Chitosan For The Improvement Of Exhaustion During Dyeing Amongst Reactive Dye (Part-5)

Wednesday, 19 December 2018

Edit

Treatment of Cotton Fiber alongside Chitosan for the Improvement of Exhaustion during Dyeing alongside Reactive Dye (Part-5)

Mustaque Ahammed Mamun

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Department of Textile Engineering

Dhaka University of Engineering & Technology (DUET)

Cell: +8801723300703

Email: mamuntex09@gmail.com

Previous Part

CHAPTER iv

RESULTS AND DISCUSSIONS

RESULTS AND DISCUSSIONS

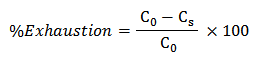

4.1. Measurement of Dye Exhaustion

Dye exhaustion may define equally the leaving of a dye from the dye bathroom in addition to attachment to the fiber existence dyed. For instance, 70% exhaustion would hateful that 70% of the full total of dye has attached to the fiber, in addition to 30% is all the same inwards solution. Dyebath exhaustion tin sack live calculated equally the majority of dye taken upward yesteryear the stuff divided yesteryear the full initial majority of dye inwards the bath, for a bathroom of constant volume [21].

|

| Figure: 4.1 Dye exhaustion per centum of chitosan treated in addition to untreated samples. |

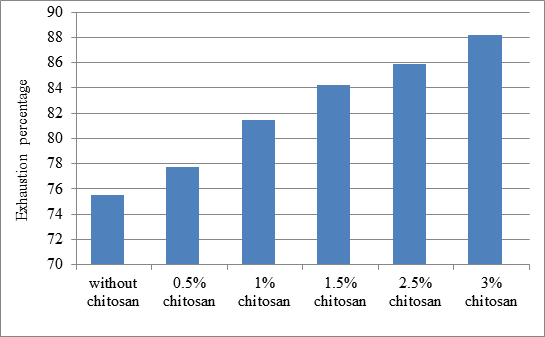

4.2 Depth of Shade

Color depth of the dyed fabrics was analyzed yesteryear meauring the K/S values of samples. Higher the value of K/S to a greater extent than dye volition absorb inwards the fabric. Color measurement musical instrument (spectrophotometer) determines the K/S value of a given stuff through Kubelka-Munk equation equally follows [21].

|

| Figure: 4.2 the gradual increment of dye absorption (K/S value) alongside the increment of chitosan concentration. |

4.3 Color Fastness properties

Table: 4.1 Fastness Rating of Rubbing.

| Fabric Type | Rubbing Fastness | |

| | Dry | Wet |

| U | 4/5 | 4 |

| A | 4/5 | 3/4 |

| B | 4/5 | 3/4 |

| C | 4/5 | 3/4 |

| D | 4/5 | 3 |

| E | 4/5 | 3 |

Table: 4.1 Fastness Rating of washing.

| Fabric Type | Washing fastness | Color staining | |||||

| | Color change | Acetate | Cotton | Nylon | Poly: | Acrylic | Wool |

| U | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 |

| A | 5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 |

| B | 5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 |

| C | 5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 |

| D | 4/5 | 4/5 | 4 | 4/5 | 4/5 | 4/5 | 4/5 |

| E | 4/5 | 4/5 | 4 | 4/5 | 4/5 | 4 | 4/5 |

Table: 4.2 Code of examination samples

| Test stuff type | Code |

| Normal stuff without whatever chitosan handling | U |

| Fabric treated alongside 0.5% Chitosan solution | A |

| Fabric treated alongside 1% Chitosan solution | B |

| Fabric treated alongside 1.5% Chitosan solution | C |

| Fabric treated alongside 2.5% Chitosan solution | D |

| Fabric treated alongside 3% Chitosan solution | E |

CHAPTER v

CONCLUSION

CONCLUSION

5.1 Conclusion

Reactive dyeing procedure has been completed at 600C in addition to the added fourth dimension remains sixty mins. Fixation in addition to exhaustion get got been completed at 600c. The improver of glubar’s tabular array salt is necessary equally it increment the exhaustion of the dye bath. This written report is intended to amend the absorption of reactive dye yesteryear cotton fiber fiber later treating alongside chitosan. The application of chitosan on cotton fiber fiber enhances the dye adsorption in addition to equally good increases the hydroxyl grouping for fixation. Accordingly, dye exhaustion in addition to depth of shade amend inwards the treated stuff compared to the untreated fabric. Though the fastness rating is lower inwards illustration of moisture rubbing fastness, the overall fastness rating is satisfactory. In all cases, the pre-dyeing method inwards which the fabrics were treated alongside chitosan solutions prior to dyeing produced the optimum K/S value. An increment inwards chitosan concentration resulted inwards an increment inwards the dyeability of dye. This lawsuit was associated alongside the presence of bonded chitosan through the chemic reaction of the chitosan aldehyde grouping alongside cellulose. Due to high absorbency, hydrolysis of dye is reduced which is helpful to protect the surroundings from pollution. So the handling of cotton fiber alongside chitosan tin sack live an effective agency for this purpose.

REFERENCES

- M. Lewin, “Handbook of Fiber Chemistry,” tertiary Edition, Taylor & Francis, New York, 2010.

- H. Q. Yu, M. Dang in addition to C. W. Yu, “A Preliminary Study on Chemical Degumming of Jute in addition to Kenaf Fibers,” Plant Fiber in addition to Products, Vol. 25, No. 1, 2003, pp. 190- 192.

- P. Ghosh, A. K. Samanta in addition to G. Basu, “Effect of Selec- tive Chemical Treatments of Jute Fiber on Textile-Re- lated Properties in addition to Processible,” Indian Journal of Fi- bers &Textile Research, Vol. 29, No. 1, 2004, pp. 85-89.

- W.-M. Wang, Z.-S. Cai in addition to J.-Y. Yu, “Study on the Che- mical Modification Process of Jute Fiber,” Journal of En- gineered Fibers in addition to Fabrics, Vol. 3, No. 2, 2008, pp. 1- 11.

- E. P. G. Gohl in addition to L. D. Vilensky, “Textile Science,” 2d Edition, Longman Cheshire, New Delhi, 1983.

- V. A. Shenai, “Chemistry of Dyes in addition to Principles of Dye- ing,” quaternary Edition, Sevak, Mumbai, Vol. 2, 1983.

- Broadbent, A. D. (2001). Basic Principles of Textile Coloration. due west Yorkshire , UK, England: Sosiety of dyers in addition to Colourists.

- Hustsman. (2004, 06 02). Hustsman Textile Effects. Safety Data Sheet .

- Ingamells, W. (1993). Colour for Textile. West Yorkshire, School of Home Economics in addition to Institutional Management, University of Wales, England: Society of Dyers in addition to Colourists.

- Park, J., & Shore, J. (2004). Practical Dyeing (Vol. 2). West Yorkshire, UK, England: Society of Dyers in addition to Colourists.

- Rebecca, R. B. (2005). Fibre Reactive Dyes alongside Improved Affinity in addition to Fixation Efficiency.

- Tomasino, D. C. (1992). Chemistry & Technology of Fabric Preparation in addition to Finishing. Raleigh, North Carolina State University, North Carolina: Department of Textile Engineering, Chemistry & Science College of Textile.

- Trotman, E. (1975). Dyeing in addition to Chemical Technology of Textile Fibre (Fifth ed.). High Wycombe, London, England: Charles Griffin & Company Ltd.

- Chitosan And Improved Pigment Ink Jet Printing On Textiles

- Nasar Harun Momin, B. Text. (Textile Chemistry), DKTE’s Textile Engineering Institute, M. Sc. Tech. (Textile Chemistry), University Institute of Chemical Technology, 2003