Yaa Dyeing Of Cotton Wool / Polyester Blended Knit Textile Alongside Reactive / Disperse Dyes Using Jet Dyeing

Friday, 14 December 2018

Edit

Dyeing of Cotton / Polyester Blended Knit Fabric alongside Reactive / Disperse Dyes Using Jet Dyeing Machine

Raihan Shobhan Rana

B.Sc inwards Textile Engineering,

Textile Engineer,

How Are You Textile Industry Ltd

Email: ranatex1@gmail.com

B.Sc inwards Textile Engineering,

Textile Engineer,

How Are You Textile Industry Ltd

Email: ranatex1@gmail.com

Pretreatment:

Generally, cotton fiber is slightly cream color & polyester fiber is almost white. Thus greyness stuff (CVC/TC) ask to endure bleach to take natural color of cotton wool as well as larn an optimum flat of whitening. Hydrogen peroxide volition bleach the cotton wool fiber. Scouring agent is used to take oil, wax as well as whatever other impurities of cotton wool fiber. This too used equally surface active agent which industrial plant betwixt fabric-liquor interface & trim down the surface tension of liquor. Emulsify fossil oil removing agent is used to take knitting fossil oil & equally good equally wetting agent. Combined scouring as well as bleaching is done to salve time, utilities & chemical.

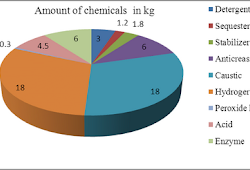

Recipe:

- Hydrogen peroxide (H2O2) 35% = v g/L

- Scouring Agent (Surfactants) = iii g/L

- Emulsify Oil Removing Agent/Wetting Agent = 0.5 g/L

- Temperature = 98°C

- Time = xxx 2nd

- M: L = 1:10

Fabric for Example: 80:20 CVC French Terry [30s/Cotton + 75D/36F polyester + 12/s (80:20) CVC]

Procedure:

- Add all substrate at room temperature as well as enhance the temperature to 98°C@3°c/min.

- Run the can for 30min at 98°C.

- After 30min driblet the temperature to a greater extent than or less 40°C (to avoid crease) as well as drain off the liquor.

- Rinse twice alongside hot (around 60°C) & mutual frigidity water. Wash off really properly to take residue peroxide stay inwards the fiber.

- Neutralize alongside acetic acid = 0.5 g/L at room temperature for 10min. (M: L=1:10)

|

| Fig: Process bend (Combined scouring as well as bleaching) |

|

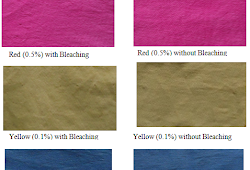

| Fig: Condition of stuff later scouring as well as bleaching |

Stage 1: Polyester business office dyeing alongside Disperse Dyes (High Temp, High Pressure)

Recipe:

- Disperse Yellow 4GSL = 0.035%

- Disperse Yellow Brown XFN = 0.09%

- Dianix Blue Ace = 0.013%

- Acetic Acid = 0.2 g/L (pH=4.4-4.6)

- Dispersing Agent = 0.5 g/L

- Bath softener = 3g/L

- Anionic softener = iii g/L

- Temperature = 130°C

- Time = 35min

- M: L= 1:10

- Add all auxiliaries & dyes at room temperature & run machine most 15min. Meanwhile banking concern check the pH of liquor & brand certain the arrive at of pH is 4.4 to 4.6. If ask add together extra acetic acid to larn the given pH range.

- Set the can at 130°C@3°C / 2nd as well as run for 35min at 130°C temperature.

- Lower downwards the can temperature to 80°C@3°C/min as well as cutting 2 samples from 2 unlike slice of fabric. If shade is ok, thence become for reduction clearing.

To banking concern check the shade of polyester business office of the fabric, cotton wool business office should endure removed yesteryear agency of carbonizing alongside sulfuric acid (generally).

- Add 50ml acid alongside 50ml H2O really slow & carefully as well as stir. (Approximate size of each sample should endure 10square cm)

- Drop the samples inwards the solution as well as stir until removal of cotton wool part.

- Wash alongside lather properly.

- Neutralize alongside ammonia as well as launder again.

Related:

Recipe:

- Sodium hydro sulfite = 2g/L

- Caustic Soda = 2g/L

- Temperature = 80°C

- Time = 20min

- M: L= 1:10

- First add together caustic soda at 80°C & run for 5min.

- Add Sodium Hydro Sulfite & laid the can at 80°C

- Run 20min at 80°C

- Gradually lower downwards the can to 40°C (to avoid crease) & Drain off the liquor & rinse alongside mutual frigidity H2O successively.

- Neutralize alongside acetic acid = 0.5 g/L at room temperature for 10min. (M: L=1:10)

|

| Fig: Fabric patch earlier as well as later carbonizing as well as dyeing |

|

| Fig: Process bend (Polyester business office dyeing alongside disperse dyes) |

Partial dye solution as well as Soda are added to dye can to avoid uneven dyeing for 80:20/ 60:40 CVC. But for stuff alongside less cotton wool nation 80:20/60:40 T/C, dye solution and soda could add together inwards brusk fourth dimension without dosing. For T/C stuff i.e. less percent of cotton, leveling agent is non necessary at all. The total of tabular array salt as well as soda varies according to color percent equally per vendor recommendation.

Recipe:

- Reactive Yellow 3RS= 0.55

- Reactive Red 3BS= 0.055

- Reactive Blue BRF= 0.035

- Glauber’s Salt (Na2SO4) = 50 g/L [As per vendor recommendation]

- Soda (Na3PO4) = 3.0 g/L [As per vendor recommendation]

- Leveling Agent= 1.0 g/L

- Bath softener for cotton= 3g/L

- Anionic softener = iii g/L

- Temperature = 60°C

- Time = 40min [As per vendor recommendation]

- M: L= 1:10

- At room temperature add together leveling agent, softener & 1/10 of total dye solution for 30min.

- At room temperature add together 3/10 of total dye solution for 30min.

- At room temperature add together 6/10 of total dye solution for 30min.

- At room temperature add together tabular array salt for 30min & enhance the temperature to 60°C @1°C/min.

- At 60°C add together 1/10 of total soda for 30min.

- At 60°C add together 3/10 of total soda for 30min.

- At 60°C add together 6/10 of total soda for 30min.

- Run the can for 40min at 60°C. (according to color percent & vendor recommendation)

- Lower downwards the can to 40°C@3°C/min as well as drain off the liquor.

- Rinse twice alongside hot (around 50-60°C) & mutual frigidity water.(To take tabular array salt & soda)

- Soap Wash (Optional)

- Treat alongside Acetic Acid =0.2g/L (To neutralize alkalis), Bath softener =5g/L, Anionic softener = v g/L, Smoothing Agent = 5g/L at 50°C for 20min. (For smoothen & softer manus experience properties).

|

| Fig: Process bend (Cotton business office dyeing) |