Now You Know Quality Control and Inspection Process of Marker Making

Tuesday, 22 January 2019

Edit

Quality Control and Inspection Process of Marker Making

Noor Ahmed Raaz

B. Sc in Textile Engineer (CU)

Specialized in Apparel Manufacturing

Merchandiser, A.M.C.S Textile Ltd (AEPZ)

Email: raju.uttara105@gmail.com

B. Sc in Textile Engineer (CU)

Specialized in Apparel Manufacturing

Merchandiser, A.M.C.S Textile Ltd (AEPZ)

Email: raju.uttara105@gmail.com

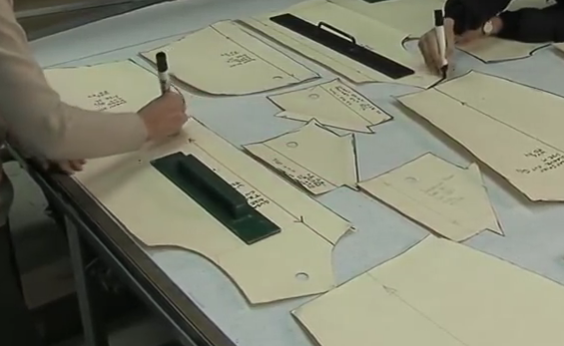

Quality control in marker making:

Marker is a thin paper which contains all the necessary pattern pieces for all sizes for a particular style of garments. It is made just before cutting and its purpose is to minimize the wastages of fabric. In case of marker making quality is very important factor. Though quality is a relative term.

The objectives of quality control in marker making can be summarized as:

- To ensure the markers are made to a size ratio that gives the required quality and quantity per order by reducing the wastage of fabrics.

- To ensure no garment part is missed in the marker and the marker is of comparable length and width of the fabric being laid.

- To check notch or drill mark

- Fabric width must be higher than marker width

- Fabric length must be higher than marker length

- Matching of green line

- Check pattern size and dimension

- Matching of check and stripe taking into consideration

- Considering garments production plan

- Cutting table length consideration

- Pattern direction consideration

|

| Marker making |

- Locations with manual marker making system: In these locations, the markers should be inspected by the Quality Control Department before the fabric is laid. This will leave sufficient time to make any correction to the marker that is necessary.

- Locations with computer marker making (CAD) system: In location that uses the CAD system, the marker information needs to be cross-checked by an operator other than one who complied the marker, before the marker is printed. This is to ensure that no operator error has occurred. The marker can then be re-inspected by the Quality Control Department after it has been placed on the lay of fabric prior to cutting.

| SL | Check points | Allowance |

| 1 | Ensure the correct patterns have been used. | No allowance |

| 2 | Ensure the size ratio is correct | No allowance |

| 3 | Ensure the correct sizes have been drawn onto the marker as per the size ratio | No allowance |

| 4 | Ensure all the garment parts have been drawn onto the marker | No allowance |

| 5 | Ensure the patterns are facing the correct direction in case of marker making modes. | No allowance |

| 6 | Ensure the patterns have been placed onto the marker in such a manner as to achieve the highest fabric utilization. | Stripes and Checks 80% & Solid color 95% |

| 7 | Ensure the marker is of the correct widths, comparable to the fabric so that the fabric is not wasted. If the marker is too small or too wide then incomplete garment parts are cut. | Zero to half inch |

| 8 | Ensure the marker is of correct length | Zero to one inch |

| 9 | Ensure splicing marks are correctly drawn on the marker. | No allowance |

| 10 | Ensure all notches and drill holes have been drawn on the marker. | No allowance |

| 11 | Ensure no unauthorized alterations have been made to the marker. | No allowance |