Yaa Why Linen Fiber Shows Pitiable Surgical Physical Care For During Abrasion?

Wednesday, 19 December 2018

Edit

Why Linen Fiber Shows Poor Performance During Abrasion?

Linen is i of the strongest natural cellulosic fibres obtained from flax constitute [Linum usitatissimum]. It’s around 2-3 times stronger than cotton.

The 2 primary fibre properties that decide the abrasion resistance are function of rupture [energy required to suspension the fibre] & breaking extension [maximum distance the fibre tin hand the sack live stretched earlier breaking].

Fibre shows practiced resistance to abrasion,

- When the fibre involve high issue energy to break.

- When the fibre tin hand the sack live stretched to a higher distance earlier breaking.

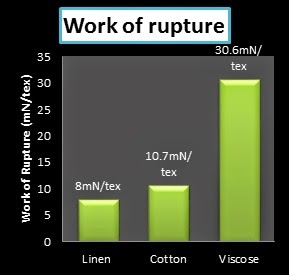

| Fibre | Tenacity | Breaking extension | Work of rupture(mN/tex) |

| Linen | 0.54 N/tex | 3.0 % | 8.0 mN/tex |

| Cotton-Upper | 0.32 N/tex | 7.1% | 10.7 mN/tex |

| Viscose | 0.18 N/tex | 27.2% | 30.6 mN/tex |

- The tenacity of linen fibre is 0.54N/tex which is greater than of cotton fiber (0.32N/tex) & viscose (0.18N/tex).

- The breaking extension of linen fibre is 3.0% which is less than of cotton fiber (7.1%) & viscose (27.2%).

- The function of rupture of linen fibre is 8.0mN/tex which is less than of cotton fiber (10.7mN/tex & viscose (30.6mN/tex).

|

| Tenacity |

|

| Breaking extension |

|

| Work of rupture |

From the higher upward comparing it’s clear that the tenacity of linen fibre is more. That is why the tensile properties of linen fibres are to a greater extent than than cotton fiber & Viscose. In example of abrasion due to the hapless extension & less function of rupture, linen fibre volition live rapidly abraded during the abrasion test.

More articles of this writer:

- Factors Affecting the Rubbing Fastness of Textile Materials

- Antimicrobial Finishing of Cotton Fabric amongst Aloe Barbadensis

- Factors Affecting the Pill Formation on Fabric

- Light Fastness of Textiles: Factors Affecting as well as Control Measures

- Chemistry Behind Yellowing of Textiles- Causes as well as Preventive Measures