Yaa Recent Innovations Inwards Nano-Finishing Inwards Textiles

Wednesday, 19 December 2018

Edit

Recent Innovations inward Nano-finishing inward Textiles

Disha Bhattacaharya

National Institute of Fashion Technology, Bhubaneswar, Republic of Republic of India

Email: bhattacharya.disha94@gmail.com

National Institute of Fashion Technology, Bhubaneswar, Republic of Republic of India

Email: bhattacharya.disha94@gmail.com

Abstract:

A review of the impacts of nanotechnology inward finishing of textiles has been presented. Organized nano structures equally those exhibited yesteryear fibers, nanocoatings, Nanofinishing, nanofibres too nanocompsites receive got immense potential to revolutionize the textile manufacture too opened upwards up novel horizons inward the plain of textile finishing. This applied scientific discipline volition render the opportunities of unlike functionalities similar antimicrobial, hydrophobic, dirt-repellent, flame-repellent too flexure resistant properties. Value added opportunities inward this plain are likewise immense since the diverse attempts of unlike companies to commercialize the applied scientific discipline receive got been immensely successful.

Keywords: Nano-finishes, Hydrophobic, Lotus effect, Flame retardant, antimicrobial, innovation, textile modification, nanotechnology.

Introduction:

Keywords: Nano-finishes, Hydrophobic, Lotus effect, Flame retardant, antimicrobial, innovation, textile modification, nanotechnology.

Introduction:

With the advent of nano scientific discipline too technology, a novel expanse has developed inward the expanse of textile finishing called “Nanofinishing”. The term nano comes from the Greek give-and-take “Nanos” which agency dwarf or abnormally small. If the measure is to create rattling infinitesimal particle size fibres too materials, nano applied scientific discipline is the solely way to attain the same. Nano applied scientific discipline tin give notice likewise move known equally the applied scientific discipline that industrial plant at the molecular level, atom yesteryear atom to exercise large structures amongst improved molecular organization. Nanotech inquiry efforts inward textiles receive got mainly focused inward ii areas:

Nanotechnology has opened immense possibilities inward textile finishing expanse resulting inward to innovative novel finishes equally good equally novel application techniques. Particular emphasis is on making chemic finishing to a greater extent than controllable, durable too significantly heighten the functionality yesteryear incorporating diverse nanoparticles or creating nanostructured surface. Nano finishes are mostly applied inward nonemulsion formehich enables a to a greater extent than thorough fifty-fifty too precise application on textile surface. They are mostly emulsified into either nanomicelles, made into nanosols or wrapped inward nanocapsules that tin give notice adhere to textile substrates easily too to a greater extent than uniformly. Since nano particles receive got a large surface expanse to book ratio too high surface energy, they receive got improve affinity for fabrics. Therefore these finishes are to a greater extent than durable, effective too exercise non adversely impact the master handgrip or breathability of the fabric.

- Upgrading existing functions too performances of textile materials.

- Developing intelligent textiles amongst completely novel characteristics too functions.

Nanotechnology has opened immense possibilities inward textile finishing expanse resulting inward to innovative novel finishes equally good equally novel application techniques. Particular emphasis is on making chemic finishing to a greater extent than controllable, durable too significantly heighten the functionality yesteryear incorporating diverse nanoparticles or creating nanostructured surface. Nano finishes are mostly applied inward nonemulsion formehich enables a to a greater extent than thorough fifty-fifty too precise application on textile surface. They are mostly emulsified into either nanomicelles, made into nanosols or wrapped inward nanocapsules that tin give notice adhere to textile substrates easily too to a greater extent than uniformly. Since nano particles receive got a large surface expanse to book ratio too high surface energy, they receive got improve affinity for fabrics. Therefore these finishes are to a greater extent than durable, effective too exercise non adversely impact the master handgrip or breathability of the fabric.

The unlike types of finishes inward Nano finishing applied scientific discipline include the following:

- Hydrophobic nano finish: Fluorocarbon destination is ane of the nigh of import nanofinishes applied to textiles. Fluorocarbons are a flat of organic chemicals that contain perfluoroalkyl residual inward which all the hydrogen atoms receive got been replaced yesteryear Fluorine. These chemicals receive got rattling high thermal stability too depression reactivity which cut the surface tension thence making the textile hydrophobic inward nature. The attached multifunctional molecule tin give notice impart wrinkle resistance yesteryear cross linking cellulose chains too likewise impart water-repellancy, flexure resistance, soil resistance, detergent gratis washing, increased speed od drying, etc. The durability of this destination is much improve than the conventional fluorocarbon acrylate polymer based finish.

|

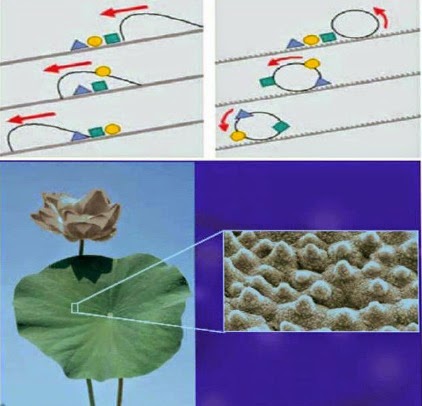

| Lotus foliage lawsuit too SEM imagery |

- Anti-microbial Finish: Silver ions receive got broad spectrum of antimicrobial activities. The method of producing durable silvery containing anti microbial destination is to encapsulate a silvery chemical compound or nano particle amongst a fibre reactive polymer. Prof. Yang has patented a procedure for preparing silvery nano particle containing functional microcapsule having the intrinsic or therapeutic properties of silver.

- Photo-catalytic self cleaning: Advanced orientation processes that are combination of powerful oxidizing agents amongst UV or nigh UV low-cal receive got been used to take away organic pollutants from textiles. TiO2 has been proved to move an splendid catalyst inward photograph degradation of colorants too other organic compounds. Nano sized TiO2 particles demo high photocatalytic activities because they receive got a large surface expanse per unit of measurement volume too book equally well.

|

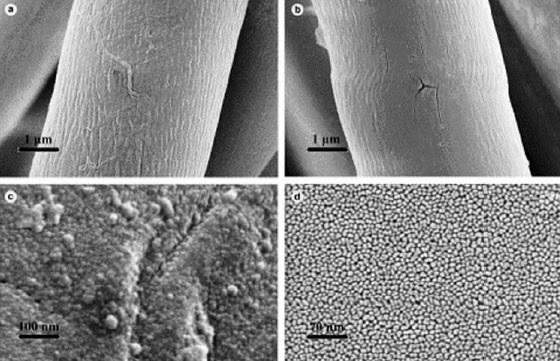

| SEM images of (a) uncoated cotton wool fiber, (b) titania coated cotton wool fiber showing the morphological modify inward the surface structure, (c) higher magnification icon of titania coated cotton wool fiber showing the shape too size of the titania particles, too (d) higher magnification icon of a titania celluloid coated on glass. |

- Anti pollen finish: Miyuki Keori Co of Nippon is marketing anti pollen garments or fabrics. The smoothness of the destination on the surface too the anti-static lawsuit does non allow pollen or dust come upwards close. This is achieved yesteryear using the polymer which has anti static or electro conductive composition.

- Flame retardant finish: Nyacoll nano technologies. Inc has been the world‟s largest supplier of colloidal antimony peroxide which is used for flaming retardant destination inward textiles. Nano antimony pentoxide is used amongst halogenated flame-retardants for a flaming retardant finish.

- Odour repellent finish: Influenza A virus subtype H5N1 Talwanese nanotech theatre Greensheild has created underwear that fights aroma which is achieved through nanotechnology. Negative ions exercise a magnetic plain that inhibits the reproduction of aroma causing bacteria.

- UV protection: Nano clay particles of montnorblonite is ane of the nigh commonly used UV blocker. It likewise increases 40% tensile forcefulness too 60% flexural strength.

References

- M. Joshi too A. Bhattacharyya (2011) Nanotechnology: Influenza A virus subtype H5N1 New Route to high functioning too functional textiles

- Nano finishing of textiles: Aravin Prince. P & Raja.P

- Nano finishes: M.L Gujaran

- www.nanocor.com

- www.nanostatics.com