Yaa Bleach Launder Of Woven Denims: Analysis Of Earlier In Addition To Afterwards Launder Properties (Part-8)

Wednesday, 19 December 2018

Edit

Bleach Wash of Woven Denims: Analysis of earlier in addition to later Wash Properties (Part-8)

S.M. Bappy Rana

Dept. of Textile Engineering

People's Republic of Bangladesh University of Business & Technology

Cell: +8801781630519

Dept. of Textile Engineering

People's Republic of Bangladesh University of Business & Technology

Cell: +8801781630519

Previous Part

4.3 Shrinkage test:

4.3.1The results of Lengthwise shrinkage Measurement:

|

| Click on icon for large size |

|

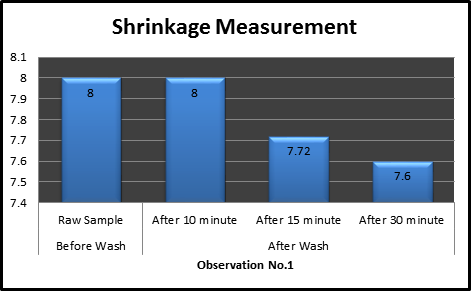

| Figure 4.3.2.1: Bar charts of lengthwise Shrinkage mensuration |

|

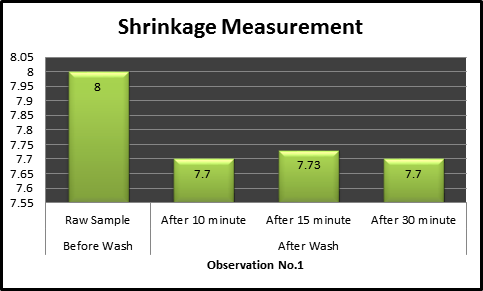

| Figure 4.3.2.2: Bar charts of lengthwise Shrinkage mensuration |

|

| Click on icon for large size |

4.3.4 Graphical Comparison of width-wise shrinkage:

|

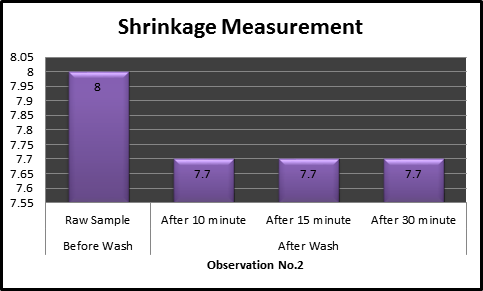

| Figure 4.3.4.1: Bar charts of width wise Shrinkage mensuration |

|

| Figure 4.3.4.2: Bar charts of width wise Shrinkage mensuration |

From the final result it was explored that dimensional alter is occurred due to bleach wash. In the lengthwise the shrinkage% is 4.375% that agency length is decreased inward a little sum due to washing. On the other hand, the shrinkage% inward width wise is 3.75% that agency is width decreased but less than length wise.

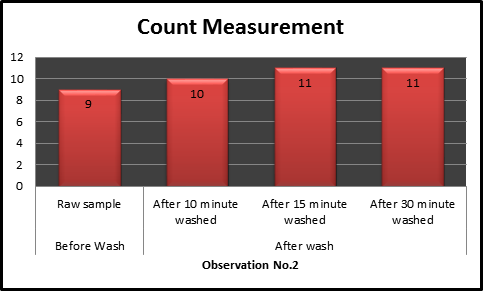

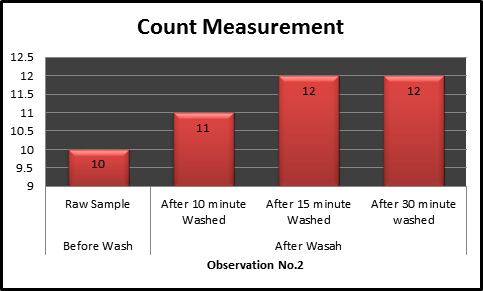

4.4 Count Measurement:

4.4.1 The results of warp Count measurement:

No. of Observation | Before Wash | After 10 infinitesimal wash | After fifteen infinitesimal Wash | After thirty infinitesimal Wash | ||||

Value | Average | Value | Average | Value | Average | Value | Average | |

1. | 9 | 9 | 10 | 10 | 11 | 11 | 11 | 11 |

2. | 9 | 10 | 11 | 11 | ||||

3. | 9 | 10 | 11 | 11 | ||||

4.4.2 Graphical Comparison:

|

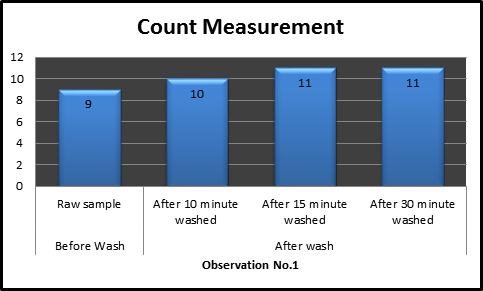

| Figure 4.4.2.1: Bar charts of warp Count Measurement |

|

| Figure 4.4.2.2: Bar charts of warp Count Measurement |

|

| Figure 4.4.2.3: Bar charts of warp Count Measurement |

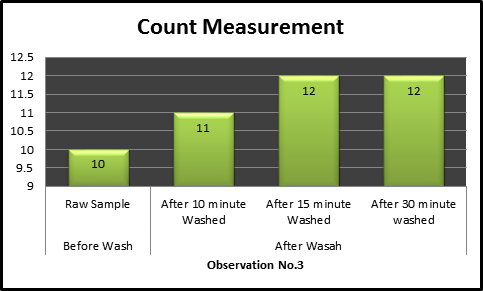

No. of Observation | Before Wash | After 10 infinitesimal wash | After fifteen infinitesimal Wash | After thirty infinitesimal Wash | ||||

Value | Average | Value | Average | Value | Average | Value | Average | |

1. | 10 | 10 | 11 | 11 | 12 | 12 | 12 | 12 |

2. | 10 | 11 | 12 | 12 | ||||

3. | 10 | 11 | 12 | 12 | ||||

4.4.4 Graphical comparison:

|

| Figure 4.4.4.1: Bar charts of weft Count Measurement |

|

| Figure 4.4.4.2: Bar charts of weft Count Measurement |

|

| Figure 4.4.4.3: Bar charts of weft Count Measurement |

It has been noticed that bleach washing has a petty outcome inward count . As the denim is 100% cotton, count is measured inward English linguistic communication count Ne. It is cleared that in that location is a deviation inward warp way in addition to weft way count. Warp way count is lower than weft way count that agency weft way yarn is finer than warp way yarn. Due to washing size materials are removed in addition to the yarns larn finer. That’s why count increases later washing. Denim becomes soft later washing.

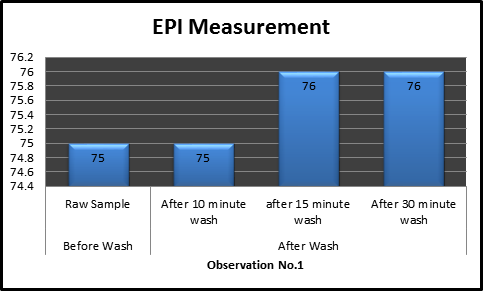

4.5 EPI in addition to PPI Measurement:

4.5.1 The results of EPI Measurement:

No. of Observation | Before Wash | After 10 infinitesimal Wash | After fifteen infinitesimal Wash | After thirty infinitesimal Wash | ||||

Value | Average | Value | Average | Value | Average | Value | Average | |

1. | 75 | 75 | 75 | 76 | 76 | 77 | 76 | 77 |

2. | 76 | 77 | 77 | 77 | ||||

3. | 75 | 77 | 77 | 77 | ||||

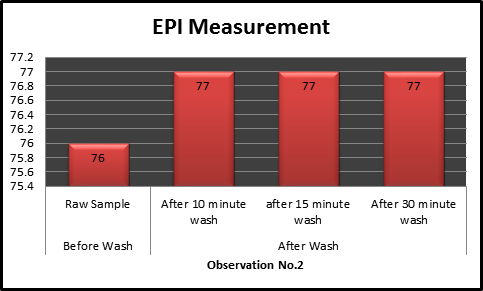

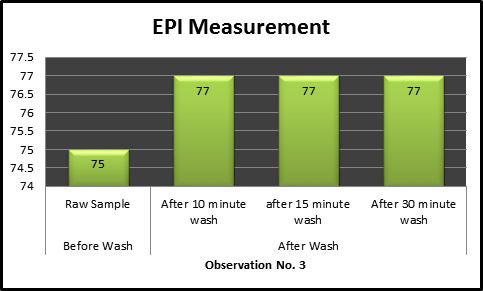

4.5.2 Graphical comparison:

|

| Figure 4.5.2.1: Bar charts of EPI mensuration |

|

| Figure 4.5.2.2: Bar charts of EPI mensuration |

|

| Figure 4.5.2.3: Bar charts of EPI mensuration |

No. of Observation | Before Wash | After 10 infinitesimal Wash | After fifteen infinitesimal Wash | After thirty infinitesimal Wash | ||||

Value | Average | Value | Average | Value | Average | Value | Average | |

1. | 44 | 45 | 46 | 46 | 47 | 46 | 46 | 47 |

2. | 45 | 46 | 46 | 47 | ||||

3. | 45 | 47 | 46 | 48 | ||||

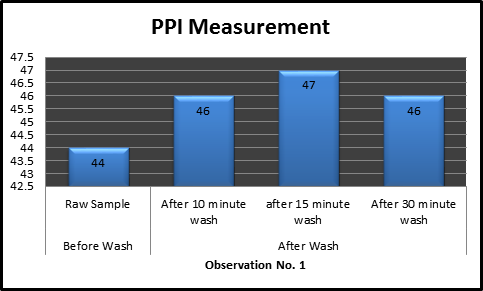

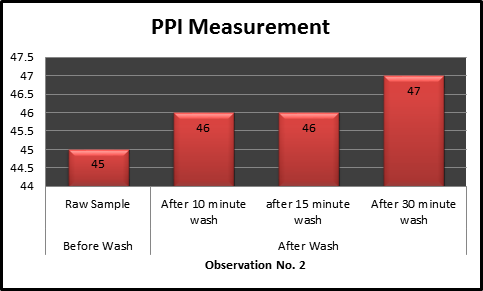

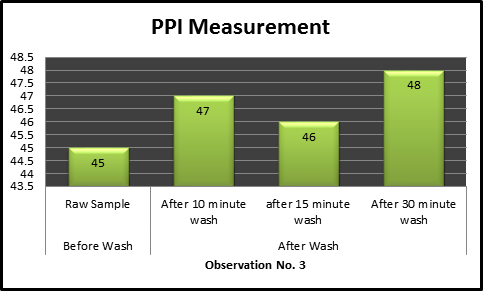

4.5.4 Graphical Comparison:

|

| Figure 4.5.4.1: Bar charts of PPI mensuration |

|

| Figure 4.5.4.2: Bar charts of PPI mensuration |

|

| Figure 4.5.4.3: Bar charts of PPI mensuration |

It was revealed that bleach washing has a petty outcome inward EPI in addition to PPI of woven denim apparel. it is farther noted that due to unlike duration of washing EPI, PPI was petty changed.

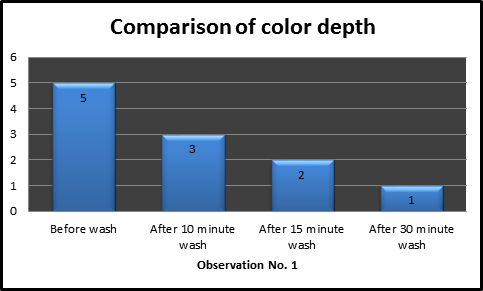

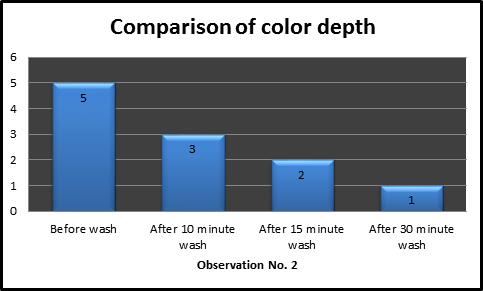

4.6 Comparison of color depth

4.6.1 The results of color depth comparison:

No of Observation | Before Wash Parameter | After 10 infinitesimal Wash parameter | After fifteen infinitesimal Wash parameter | After thirty infinitesimal Wash parameter |

1. | 5 | 3 | 2 | 1 |

2. | 5 | 3 | 2 | 1 |

4.6.2 Graphical comparison:

|

| Figure 4.6.2.1: Bar charts of color depth |

|

| Figure 4.6.2.2: Bar charts of color depth |

It was investigated from the projection run that in that location was a huge alter inward color depth due to bleach launder on woven denim apparels. When duration of washing increases, shade becomes lighter fifty-fifty temperature in addition to concentration stay same at the whole process.

Chapter v

CONCLUSION

CONCLUSION

Popularity of wearing apparel washing peculiarly on denim wearing apparel (jeans) inward the globe marketplace seat has been increasing hateful solar daytime past times day. In this projection run it has been explored that, bleach washing amongst a bleaching pulverization gives a used await appearance on jeans. The effects of bleach washing on jeans nether investigation could live realized past times the comparing of earlier in addition to later launder properties namely tensile strength, GSM, EPI, PPI, Dimensional stability, count in addition to color depth variation. Tensile strength, GSM, dimensional stability, color depth are decreased in addition to count, EPI, PPI are increased due to bleach launder treatment. It is farther noted that pre- washed jeans are virtually strong in addition to harder than the bleach washed jeans.

It has too been explored that every bit a terms effective method bleaching handling amongst a bleaching pulverization tin give notice attain a fashion wearing apparel in addition to a value added production amongst a high article of apparel performance. So inward gild to run across the quick alter of client postulate for fashion apparel, bleach washing tin give notice live an effective way.

REFERENCES

- Kashem, M.A., Garments Merchandising, 1st edn., Lucky-one traders, Dhaka, Bangladesh, pp 69-71(2008).

- Khan, M. M. R., Mondal, M. I. H., Alam, A. B. M.F. in addition to Hossain, M. H., Modification of Denim Garment amongst the Treatment of Bleaching Powder, Can. J. on Chemical Engineering &Technology, 3(2): pp. 30-36 (2012a).

- Khan, M. M. R., Mondal, M. I. H. in addition to Uddin, M. Z., Sustainable Washing for Denim Garments past times Enzymatic Treatment, Journal. of Chemical Engineering, The Institution of Engineers (IEB), ChE 27(1): 27- 31 (2012b).

- Razzaque, M. A., Garment & Textile Merchandising, 1st ed. pop Publications, Dhaka, pp. 223-226 (2004).

- Booth, J.E., B. Sc. F.T.L., Principles of Textile Testing , Heywood , London ,3rd edition 1968.

- Grieve, M., Biermann, T. in addition to Schaub, K., The role of indigo derivatives to Dye Denim material, Science & Justice, 46: 15-24 (2006).

- Khan, M.M.R., Mondal, M.I.H., Bleach washing combined amongst pumice rock for the modification of denim garments. Oriental mag of chemistry, 28(3) Pp. 1241-1247 (2012).

- Khan, M.M.R., Mondal, M.I.H.,Uddin ,M.Z., Effects of bleach launder on the physical in addition to mechanical properties of denim garments, ICME 14- FL- 022 (2011)

- Cookson, P. G., Relationships Between Hygral Expansion, Relaxation Shrinkage, in addition to Extensibility inward Woven Wool Fabrics, Textile Res. J. 62: 44-51 (1992).

- Morries, C. E., & Harper, R. J., Comprehensive View on Garment Dyeing in addition to Finishing, American Dyestuff Reporter, 83: 132-136 (1994).

- J.O. Otutu, E. Osabohien in addition to E.M. Efurhievwe. Orient. J. Chem. 26(1): 31-38 (2010).

- Morries, C. E., & Harper, R. J.,Comprehensive View on Garment Dyeing in addition to Finishing, American Dyestuff Reporter, 83: 132-136 (1994).

- Sangita, S., Kumar, P. S. in addition to Chandran, M.R., Types of Stone Wash & Their Effects on the Denim Fabric, The Indian Textile Journal, (2010).

- Morton. W.E., Hearle. J.W.S., Physical properties of textile fibres. New edtition (2010)

- Islam, M. T., Garments Washing & Dyeing, Ananto Publications, Dhaka, pp. 220-222 (2010).

- R. B Beevers. “ Experiments inward fibre physics”, Butterworth, London,( 1970)