Now You Know Scope of Seam Engineering to Increase the Seam Strength by Controlling Different Parameters (Part-1)

Saturday, 2 June 2018

Edit

Scope of Seam Engineering to Increase the Seam Strength by Controlling Different Parameters (Part-1)

Authors: MD. Momenur Rahman,

Kazi Mustafijur Rahman

Rabeya Siddiqua

Atish Dipankar University of Science and Technology

Dhaka, Bangladesh

Kazi Mustafijur Rahman

Rabeya Siddiqua

Atish Dipankar University of Science and Technology

Dhaka, Bangladesh

Abstract

- Stitches and seams are two important elements of apparel construction.

- Stitches are used to join the materials and hold the apparel together, and seams give the shape/contour and detail of the apparel.

- These two elements together with the material properties contribute to the quality of the apparel.

- Change in parameters in terms of Sewing Thread Size/Ticket Number, GSM, Stitch Per Inch (SPI) & Stitch Per Minute (SPM) are necessary parameters to calculate different types of variation and variable on which the whole fabric construction depends.

- The purpose of this study is to investigate the performance of seam quality in terms of seam appearance and strength constructed with different sewing parameters.

A. Investigating the performance of seams constructed with different sewing parameters.

- The seam quality is defined by appearance and strength.

- Seams are constructed with different sewing parameters which include the types and sizes of threads, needle sizes and stitch densities for five fabric weight categories.

B. To validate the predictive equation using new fabrics for each category of fabric weight.

- Comparison between experimental and predictive evaluation of seam quality is done in order to measure the effectiveness and limitations of the equations.

Seam - joining of pieces of fabric together with stitching

|

| Fig: Seam |

- Seam Performance (Functional Properties)

- Seam Appearances (Aesthetic Properties)

- Seam Strength

- Seam Elasticity

- Seam Durability

- Seam Comfort

- Seam Security

The mechanism through which the strength or seam is controlled by improving its different aspects.

Factors that Effect Seam Strength

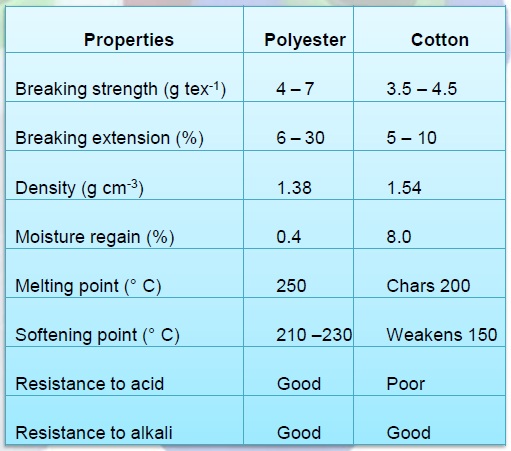

- Fabric type and weight.

- Thread fiber type, construction, and size.

- Stitch type.

- Stitches density (SPI).

- Stitch balance.

|

(Ukponmwan, Mukhopadhyay et al. 2000)

|

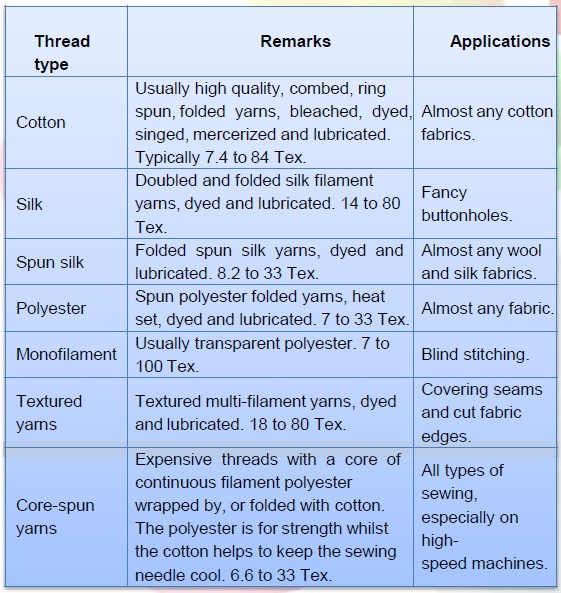

- A few different systems are available for producing the ticket number but the systems are mostly based on the weight and thickness of the sewing thread.

- The two most common systems are Tex and Metric.

- Thicker and heavier sewing threads have a higher value of Tex and smaller value of Metric number.

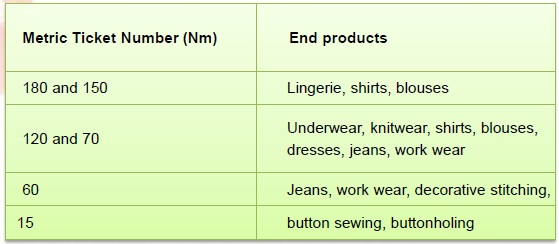

Examples of end product with suggestions of suitable ticket number of thread to be used during production (Carr and Latham 2000)

|

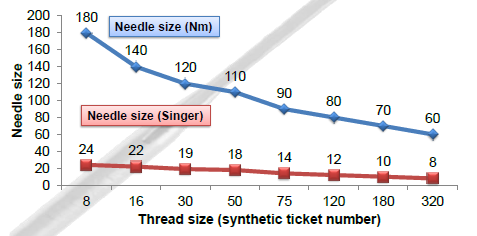

The way the needle penetrates the fabric during sewing will give different effects in respect of seam strength (Stjepanovic and Strah 1998)

Needle size for different thread size

|