Now You Know An Overview of Compression Garments

Friday, 8 March 2019

Edit

An Overview of Compression Garments

Introduction:

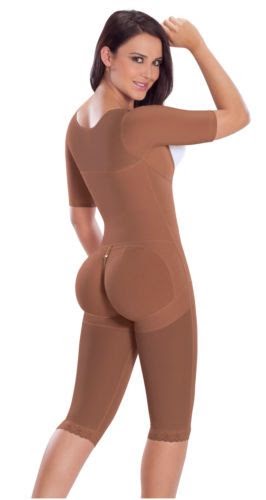

Compression garments are pieces of clothing, such as socks, pantyhose, sleeves, etc., that provide support that is especially useful for people who have to stand for long periods, or people with poor circulation. The garments can come in varying degrees of compression. The higher degrees require a doctor's prescription. Compression garments worn on the legs can help prevent deep vein thrombosis and reduce swelling, especially while travelling.

|

| Compression garments |

Background:

CG’s were first introduced around 50 years ago where they were mainly used as a medical stocking to create pressure around muscle, bone and connective tissue. They had a gradient compressive force measured in millimetres of mercury. As you can see in the picture, the force is greatest at the ankle and decreases as the garment moves up the body (Ali, Creasy & Edge, 2010). CG’s were originally used to help treat patients with poor venous blood flow in the lower leg and foot. This is the flow of deoxygenated blood returning to heart from the peripheral limbs (Wallace, Slattery & Coutts, 2008). The purpose of these garments has developed over the years and is now becoming an increasingly popular training aid amongst athletes and sports teams.

Types of Compression Garments:

The types of compression garment’s vary where they can be worn as lower, upper or full-body pieces made mainly from nylon and spandex (or Lycra) materials. There are also compression sleeves and stockings worn to support limbs and joints.

|

| Types of Compression Garments |

Different yarns can be used for example polyester, terylene or any other yarn. For elasticity spandex is introduced in the fabric structure.

Fabric Formation Technique:

There are two techniques used for CG’s. One is for seamless garments and other with seams.

Circular (round) knitted garments:

Are produced in one piece, with no seam, and tend to be mostly available ‘off the shelf’, although custom-made varieties can also be obtained. Because a fixed number of needles are used during garment production, there are restrictions for the type of swelling they can be used for. In general, they are recommended for those who have an early/mild oedema (Stage l) with an excess fluid volume of less than 20% when compared to the unaffected limb. However, they can also be used for those who have moderate lymph oedema (Stage ll) as long as the swollen limb is an even/uniform shape. Circular knitted garments generally have a finer finish and are more cosmetically pleasing, but if there is any limb shape distortion (even if the limb is small) they may not work as well (and can prove uncomfortable), and flat bed knitted garments should be considered.

Flat bed knitted garments

Are made as a flat piece, to specific measurements, which are then joined together with a flat seam. They are recommended for those who have moderate to severe oedema (Stages ll/lll) with an excess fluid volume of more than 20%. These garments are strongly recommended for those who have just undergone a course of MLLB, or who have limb shape distortion with creases and folds in the tissues. These garments tend to be slightly more expensive and require accurate, specific measurements for an optimum, precise fit. They are possibly not as popular with patients because they appear thicker, coarser and ‘stiffer’ (due to the thicker yarns used in production). However, if recommended by your lymph oedema practitioner/therapist, please persevere with them – they can help considerably in controlling your swelling.

Manufacturing Process of Compression Garments:

Manufacturing medical compression garment requires that strict guidelines to be followed and is submitted to several strict controls. The three main objectives are to reach optimal therapeutic efficacy, product reliability and best comfort.

There are six steps in the manufacturing process:

- Yarn covering

- Knitting

- Sewing

- Boarding

- Dyeing

- Packaging

The yarns that will hold the "active principle" of the compression medicine must be prepared before being knitted. Yarn covering will enable to master the "strength-stretch" parameters and to protect the elastic yarn.

The covering will consist of covering elastic yarns (natural latex, elastane) and natural fibres (cotton, wool) or synthetic (microfiber) by regular helicoidal roll-ups of one or two yarns. Once covered, the yarns must rest for at least two weeks in order to stabilize.

2. Knitting

The medical compression articles are knitted on circular machines. These machines are especially made for medical stockings. The different sizes are achieved on machines with different diameters. The diameter is changed according to the desired size.

The knitting process is made under operator’s supervision. They are in charge of the visual and technical controls of the products. It takes about 3 minutes to knit a medical stocking.

3. Sewing

several cutting and sewing operations are realized to put the article together (hem sewing, toe closing, assembly, elastic sewing...) these tasks are very precise. Comfort and solidity of the product will depend on the quality of those operations.

4. Boarding

during the knitting process, the articles are more or less stretched. This creates size differences between two consecutive stockings. Boarding process will give a stabilized size to the articles.

The boarding process is made of two steps. First, the knitting relaxation is done before the dyeing process. The knitting’s go through a forming machine or are steam ironed. The second step is the pre-boarding. It is an operation to prepare the article for the dyeing process.

5. Dyeing

A dyeing cycle lasts about 5 hours and counts four steps:

- Washing

- Dyeing

- Pre-spinning

- Spinning

6. Packaging

After the dyeing and boarding processes, the articles are put in pairs and are all carefully controlled. Labels are sewed in. Then, the stockings are folded up, placed in a plastic protection and put in a box. Boxes are labelled and put in stock.

Benefits of wearing compression garments:

Your compression garment has the following main benefits:

- It limits the amount of fluid building up in the limb. Normally there is a constant flow of fluid from the tiny blood vessels into the tissues. This fluid is then drained by the lymph system. Pressure from your garments reduces any excessive or unnecessary flow of fluid from the blood stream into the tissues.

- It will provide the muscles with a firm resistance to work against, thereby improving the function of the lymphatics and encourage the movement of fluid along the lymph routes. It is essential you wear your compression garment during exercise – all benefits gained during the exercise will be lost if you don’t.

- It enables fluid within the limb to move towards the body where it will drain away more easily (especially in conjunction with Simple/Manual Lymphatic Drainage). Because the compression garments have a graduated compression (more strength at the foot/hand than at the top of the garment), the fluid is directed to the root of the limb (groin/armpit).

- It will provide support to inelastic tissues, often noticeable following an intensive course of treatment, when a large amount of fluid has been removed from the limb, leaving loose, and sagging skin/tissues.

- It helps to soften firm, hard (fibrous) tissues due to the massaging effect of the garment against the skin during movement/exercise.

Use for following reasons.

- Assessment of your arterial circulation (to ensure that pressure from the garment does not cut off the blood supply to your fingers or toes)

- The shape and overall size of your limb

- Severity of the swelling

- Skin condition

- Your overall builds (height, weight)

- Athletes

- Media

- Fashion

- Sports clothing

- Edema

- Lymphoedema

- Phlebitis

- Post-thrombotic syndrome

- Vascular malformations

- Post-liposuction

1. Composition test

(ISO 1833:2006)

92% polyester, 8% rubber

Design

2x1 Rib, 2 faces, 1 back

19Wales/inch, 16courses/inch

2. GSM test

(ASTM D 3776)

Weight of 5’x5’ sample , multiply by 400

Weight =0.75x400 = 300g

3. Test method of thickness of textile materials

(ASTM D 1777)

Thickness = 1.82mm

4. Compression test

(ASTM D 1776-04)

On top =22 mmHg (mm of mercury)

Ankle =16 mmHg (mm of mercury)

5. Test method for Air permeability of textile fabrics

(ASTM D 737)

Pressure = 100Pa

Area = 20Cm2

Mm/Sec = 585

6. Test method of stretch properties of textile fabric by CRE Method.

(Elongation Test) (ASTM D6614)

Knitted sample

Sample Passed | Direction | Preload/stress (N) | Preload/stress Speed (mm/min) | Speed (mm/min) | Gauge length (mm) | Limit (mm) | Hold time (s) |

True | Tension | 5.6 | 21 | 100 | 200 | 100 | 300 |

Time stamp | Percentage Total Elongation At Maximum Force | Load At Maximum Load (N) |

4/30/2014 10:49:41 AM | 50.02911014 | 782.4896528 |

Load at Maximum Extension (N) | Strain at Maximum Extension | Percentage Strain at Maximum Extension |

781.6315619 | 0.5003058 | 50.03058005 |