Now You Know Polyester/Cotton (P/C) Blends Fabric Dyeing: Recipe, Parameters, Flowchart and Dyeing Curve

Monday, 21 January 2019

Edit

Polyester/Cotton (P/C) Blends Fabric Dyeing: Recipe, Parameters, Flowchart and Dyeing Curve

Engr. Kazi Zakaria Ahmed

M.Sc. in Applied Chemistry & Chemical Technology (IU)

B.Sc. in Textile Engineering (DU)

Lecturer, Department of Garments & Textile Engineering

BCMC COLLEGE OF ENGINEERING & TECHNOLOGY

Jessore-7400, Bangladesh

E-mail: iamzakdude@gmail.com

M.Sc. in Applied Chemistry & Chemical Technology (IU)

B.Sc. in Textile Engineering (DU)

Lecturer, Department of Garments & Textile Engineering

BCMC COLLEGE OF ENGINEERING & TECHNOLOGY

Jessore-7400, Bangladesh

E-mail: iamzakdude@gmail.com

RECIPE AT DIFFERENT STAGES IN DYEING COTTON FABRIC:

PRETREATMENT | |

Ingredient | Quantity |

Wetting agent (Sun Mori CK-1) | 0.5 g/l |

Anti creasing agent (Texport D – 600) | 1.3 g/l |

Sequestering agent (Sirrix-SQ) | 0.5 g/l |

Caustic | 3 g/l |

Stabilizer (Neorate PH-100 ) | 1 g/l |

Hydrogen per oxide (H2O2) | 3.5 g/l |

Peroxide killer(Crocks-N) | 1 g/l |

Neutralization | |

Acetic acid | 1 g/l |

Enzyme treatment | |

Acetic acid | 0.3 g/l |

Bio –polish EC | 1 g/l |

Dyeing | |

Acetic acid for leveling agent | 0.3 g/l |

Levelling agent (Neocrystal EDX/200B) | 1 g/l |

Anti creasing agent (Texport D – 600) | 1.5 g/l |

Dyes | |

Salt | 40% owf |

Soda | 15% owf |

After Treament | |

Fixing agent (Neofix ECO/Cibafix FRD) | 0.5 g/l |

Soaping agent(Lipotol PS-60) | 0.8 g/l |

Acetic acid | 1 g/l |

SOFTENING | |

Acetic acid | 0.2 g/l |

Softener( Perrostol CWS) | 1 g/l |

Table No-1: Recipe at different stages in cotton dyeing.

Different parameters in DYEING:

Process of Polyester/Cotton (p/C) Fabric dyeing:

RECIPE FOR MACHINE WASH:

Ingredient | Amount |

Detergent (Solax) | 0.5 gm/L |

Caustic | 1 gm/L |

Hydrous | 2 gm/L |

Table No- 2: Recipe for m/c wash.

Different parameters in DYEING:

A. pH | |

During peroxide bleaching & scouring | 9-11 |

During enzyme treatment | 4.5-5 |

Before addition of leveling agent | 6-6.5 |

Before addition of color softener(Perrustol IMA-500) | 6-6.5 |

Before addition of white softener(Perrustol VNO-500) | 4.5-5 |

Softener at stenter & de-watering | 5.5-6 |

Silicon softener | 5.5-6 |

10.5-12 | |

4.5-5.5 | |

B. Temperature | |

For cotton scouring | 95-110˚C |

For cotton cold wash | 40-50˚C |

For cotton hot wash | 70-80˚C |

For cotton acid wash | 60-70˚C |

For cotton dyeing | 80˚C ( For hot brand)/60˚C(For cold brand) |

C. Time | |

For scouring and bleaching | 60-90 minutes |

For reactive dyeing | 60-90 minutes |

For disperse dyeing | 60-90 minutes |

Table No-3: Different parameters of dyeing.

Process of Polyester/Cotton (p/C) Fabric dyeing:

- At first the Polyester Part dyeing same as Polyester Dyeing.

- Then the Cotton Part dyeing same as Cotton Dyeing.

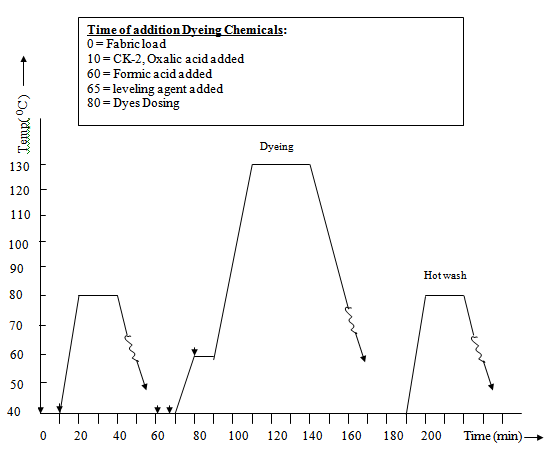

Dyeing Procedure of polyester fabrics with Curve:

Required amount of water filled

↓

Fabric was loaded and run for 10 min.

↓

Drain

↓

Required amount of water filled

↓

CK-2 and oxalic acid was added for 5 min.

↓

Run for 20 min. at 800C

↓

Rinse for 15 min.

↓

Drain

↓

Required amount of water filled

↓

Formic acid added for PH- controlled

↓

Check PH at 4.5

↓

Leveling agent (DIF) added for 10 min.

↓

Temperature increase at 600C

↓

Color/Dyes added for 15 min.

↓

Run for 10 minutes

↓

Temperature increases at 1300C for 30 min.

↓

Run for 30 minutes

↓

Cooling at 800C

↓

Shade check

↓

Rinsing for 15 min.

↓

Drain

↓

Required amount of water filled

↓

Hot wash at 800C

↓

Shade check

↓

Rinsing for 15 min.

↓

Unloading

Required amount of water filled

↓

Fabric was loaded and run for 10 min.

↓

Drain

↓

Required amount of water filled

↓

CK-2 and oxalic acid was added for 5 min.

↓

Run for 20 min. at 800C

↓

Rinse for 15 min.

↓

Drain

↓

Required amount of water filled

↓

Formic acid added for PH- controlled

↓

Check PH at 4.5

↓

Leveling agent (DIF) added for 10 min.

↓

Temperature increase at 600C

↓

Color/Dyes added for 15 min.

↓

Run for 10 minutes

↓

Temperature increases at 1300C for 30 min.

↓

Run for 30 minutes

↓

Cooling at 800C

↓

Shade check

↓

Rinsing for 15 min.

↓

Drain

↓

Required amount of water filled

↓

Hot wash at 800C

↓

Shade check

↓

Rinsing for 15 min.

↓

Unloading

Reduction Cleaning-

Caustic Dosing (600C X 6 min)

↓

Raising Temp at 1300C

↓

Hydrose injection

(Run time- 10 min at 800C)

↓

Normal wash

↓

Drain

Caustic Dosing (600C X 6 min)

↓

Raising Temp at 1300C

↓

Hydrose injection

(Run time- 10 min at 800C)

↓

Normal wash

↓

Drain

|

| Figure-1: Dyeing Curve of Polyester. |

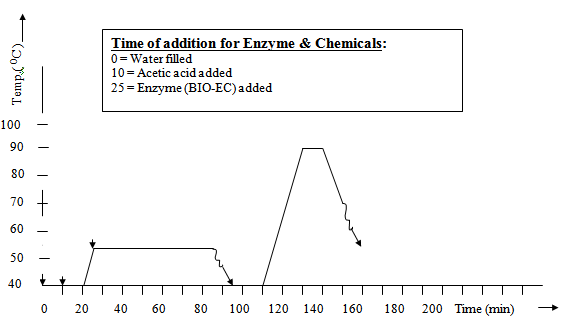

Cotton Dyeing Steps with Curve:

Required amount of water was taken into the machine

↓

The fabric was loaded and run for 5-10 minutes in normal temperature

↓

CK-2,D-600/C,SQ-12UD and PH-100 (Scouring Chemicals) were added at a time for 5 minutes

↓

Caustic was added at normal temperature for 5 minutes

↓

Temperature increased at 600C

↓

Hydrogen per Oxide(H2O2)was added for 5 minutes

↓

Temperature increased at 950C and continue for 1 hrs

↓

Sample check

↓

Cold wash at 400C for 5-10 minutes

↓

Hot wash at 950C for 5-10 minutes

↓

Required amount of water was loaded

↓

Croak-N was added

↓

Acetic acid was added

↓

Temperature increased at 800C for 15-20 minutes

↓

Cold wash at 400C and drain

↓

Water filled and Acetic acid was added

↓

PH check at 4.5

↓

Temperature increased at 550C

↓

Enzyme (Bio-EC) was added and run for 1hrs at 550C

↓

Shade check

↓

Cold wash at 400C and drain

↓

Water filled/Required amount of water was taken

↓

Temperature increased at 95-990C for 5-10 minutes

↓

Cold wash at 400C and drain

↓

Acetic acid was added

↓

PH check at 4.5

↓

EDX/200B and C/D-600 were added at a time

↓

Salt dosing

↓

Color dosing for 30 min

↓

Run for 10 min

↓

Soda dosing for 40 min

↓

Run for 7 min

↓

Temperature increase at 600C for 5 min

↓

Run for 10 min

↓

Shade check (OK)

↓

Rinsing

↓

Water was filled at required amount

↓

PS-60 was added

↓

Temperature increase at 800C for 10 min

↓

Hot wash at 900C for 20 min and shade check in this time (OK)

↓

Rinsing

↓

Water was filled at required amount

↓

Acetic acid was added for neutralization for 10 min

↓

Shade check (ok)

↓

ECO/FRD was added for 10 min

↓

Rinsing

↓

Water was filled at required amount

↓

PH check at 6.5

↓

(C.W.S) softener was added

↓

Final shades check and run for 20 min

↓

Unload the dyed fabric

Required amount of water was taken into the machine

↓

The fabric was loaded and run for 5-10 minutes in normal temperature

↓

CK-2,D-600/C,SQ-12UD and PH-100 (Scouring Chemicals) were added at a time for 5 minutes

↓

Caustic was added at normal temperature for 5 minutes

↓

Temperature increased at 600C

↓

Hydrogen per Oxide(H2O2)was added for 5 minutes

↓

Temperature increased at 950C and continue for 1 hrs

↓

Sample check

↓

Cold wash at 400C for 5-10 minutes

↓

Hot wash at 950C for 5-10 minutes

↓

Required amount of water was loaded

↓

Croak-N was added

↓

Acetic acid was added

↓

Temperature increased at 800C for 15-20 minutes

↓

Cold wash at 400C and drain

↓

Water filled and Acetic acid was added

↓

PH check at 4.5

↓

Temperature increased at 550C

↓

Enzyme (Bio-EC) was added and run for 1hrs at 550C

↓

Shade check

↓

Cold wash at 400C and drain

↓

Water filled/Required amount of water was taken

↓

Temperature increased at 95-990C for 5-10 minutes

↓

Cold wash at 400C and drain

↓

Acetic acid was added

↓

PH check at 4.5

↓

EDX/200B and C/D-600 were added at a time

↓

Salt dosing

↓

Color dosing for 30 min

↓

Run for 10 min

↓

Soda dosing for 40 min

↓

Run for 7 min

↓

Temperature increase at 600C for 5 min

↓

Run for 10 min

↓

Shade check (OK)

↓

Rinsing

↓

Water was filled at required amount

↓

PS-60 was added

↓

Temperature increase at 800C for 10 min

↓

Hot wash at 900C for 20 min and shade check in this time (OK)

↓

Rinsing

↓

Water was filled at required amount

↓

Acetic acid was added for neutralization for 10 min

↓

Shade check (ok)

↓

ECO/FRD was added for 10 min

↓

Rinsing

↓

Water was filled at required amount

↓

PH check at 6.5

↓

(C.W.S) softener was added

↓

Final shades check and run for 20 min

↓

Unload the dyed fabric

|

| Figure-2: Scouring & Bleaching Curve. |

|

| Figure-3: Enzyme Treatment Curve. |

|

| Figure-4: Dyeing Curve of Cotton. |