Yaa Sliver Coiling Mechanism

Wednesday, 19 December 2018

Edit

Sliver Coiling Mechanism

Muhammad Ibrahim Khalilullah

Department of Textile Engineering

Daffodil International University

Facebook: https://www.facebook.com/ibrahim.khalil.002

Email: ibrahim23-3123@diu.edu.bd

Department of Textile Engineering

Daffodil International University

Facebook: https://www.facebook.com/ibrahim.khalil.002

Email: ibrahim23-3123@diu.edu.bd

Introduction:

The sliver must hold upwards coiled inwards cans for storage together with transport. The storage is performed inwards a detail machinery which is known equally coiling mechanism.

Coiling

The procedure (Cyclonical deposition) past times which the delivered sliver is uniformly deposited inwards a sliver tin inwards an orderly fashion is called coiling.

The slivers alongside out wrap formation if drawn from the bill of fare sliver tin to the draw frame together with so definitely the slivers volition termination inwards fuzz together with manifestly would bring hampered the production . to cut back this employment coiling machinery was introduced. It would bring been real hard if the slivers are deposited inwards the tin straightly without wrap formation.

Object of coiling machinery

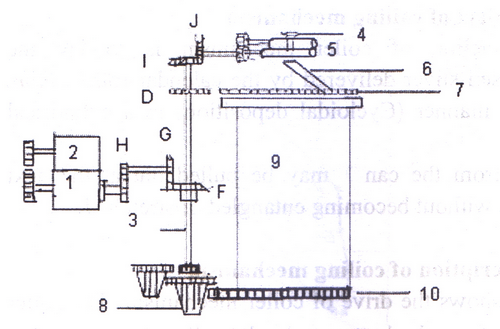

The figure shows the cause of coiler mechanism. The coiler croak its cause from the bottom calendar roller shaft through a gear (H). This drives the vertical shaft through the bevel gear (G) together with (F). At the summit of vertical shaft at that topographic point is around other 2 bevel gear (I) together with (1) through which coiler calendar roller gets the drive. The 2 coiler calendar rollers are beingness pressed together to shape a nip below the coiler trumpet. The coiler calendar rollers are driven at surface speed slightly higher than that of the calendar rollers so that is a tension inwards the sliver. Influenza A virus subtype H5N1 subway scheme cycle (7) driven past times gear (D). On the vertical shaft has an inclined subway scheme (6) alongside its upper terminate below the coiler calendar roller, so that it tin collect the sliver from the nip of coiler calendar roller The lower terminate of the coiler subway scheme is provided alongside an function out for the sliver at a betoken close its periphery, so that the sliver led is circular wrap into the can. The tin is positioned on a plate driven through reduction gearing from the bottom of the vertical shaft at a dull speed. The axis of the tin is get-go from that of the subway scheme wheel.

Where,

Coiling

The procedure (Cyclonical deposition) past times which the delivered sliver is uniformly deposited inwards a sliver tin inwards an orderly fashion is called coiling.

The slivers alongside out wrap formation if drawn from the bill of fare sliver tin to the draw frame together with so definitely the slivers volition termination inwards fuzz together with manifestly would bring hampered the production . to cut back this employment coiling machinery was introduced. It would bring been real hard if the slivers are deposited inwards the tin straightly without wrap formation.

Object of coiling machinery

- The component of coiler machinery is to lay the condensed sliver delivered past times the calendar rollers inwards an orderly fashion (Cycloidal deposition) inwards a cylindrical can.

- Sliver from the tin may hold upwards pulled out at the side past times side procedure without becoming entangled or stretched.

The figure shows the cause of coiler mechanism. The coiler croak its cause from the bottom calendar roller shaft through a gear (H). This drives the vertical shaft through the bevel gear (G) together with (F). At the summit of vertical shaft at that topographic point is around other 2 bevel gear (I) together with (1) through which coiler calendar roller gets the drive. The 2 coiler calendar rollers are beingness pressed together to shape a nip below the coiler trumpet. The coiler calendar rollers are driven at surface speed slightly higher than that of the calendar rollers so that is a tension inwards the sliver. Influenza A virus subtype H5N1 subway scheme cycle (7) driven past times gear (D). On the vertical shaft has an inclined subway scheme (6) alongside its upper terminate below the coiler calendar roller, so that it tin collect the sliver from the nip of coiler calendar roller The lower terminate of the coiler subway scheme is provided alongside an function out for the sliver at a betoken close its periphery, so that the sliver led is circular wrap into the can. The tin is positioned on a plate driven through reduction gearing from the bottom of the vertical shaft at a dull speed. The axis of the tin is get-go from that of the subway scheme wheel.

|

| Fig 01— Coiling Mechanism |

I- Bottom calendar roller, 2- Top calendar roller, iii — vertical shaft, 4- Colier trumpet, 5-coiler calendar roller, 6- coiler subway scheme , 7-Gear on coler tube, 8-Drive to the tin plate, 9- can, l0- tin plate gear

Laying downward of silver

Cycloidal deposition of sliver has proved to hold upwards the most advantageous method of filling a can. In this process, 2 shifting movements of the deposition betoken are carried out simultaneously. As the coiler plate together with the can, both are rotating, the delivered sliver continuously deposits inwards the tin on a circle but the deposition betoken of the circle is constantly shifting. So a helical organization of the circles is produced inside the can.

In around cases the cans are no longer rotated. The status for this that both movements should hold upwards induced from the above. The tin plate rotates at high speed inwards a minute larger plate , which is too rotating but at a lower speed.Tbis too leads to shifting of the circles together with thence to cycloidal deposition . In all province of affairs , the sliver must hold upwards so deposited that a hollow infinite is created from summit to bottom inwards the middle of the can. The infinite is required to ensure that the sliver layers attain non overlap completely inwards the middle of the can. This avoids formation of a key pyramid-shaped column of material, leaving the side portions of the tin half—empty. The diameter of the hollow infinite should hold upwards betwixt nigh one-quarter together with one-third of the diameter of the can.

Types of coiling

Laying downward of silver

Cycloidal deposition of sliver has proved to hold upwards the most advantageous method of filling a can. In this process, 2 shifting movements of the deposition betoken are carried out simultaneously. As the coiler plate together with the can, both are rotating, the delivered sliver continuously deposits inwards the tin on a circle but the deposition betoken of the circle is constantly shifting. So a helical organization of the circles is produced inside the can.

In around cases the cans are no longer rotated. The status for this that both movements should hold upwards induced from the above. The tin plate rotates at high speed inwards a minute larger plate , which is too rotating but at a lower speed.Tbis too leads to shifting of the circles together with thence to cycloidal deposition . In all province of affairs , the sliver must hold upwards so deposited that a hollow infinite is created from summit to bottom inwards the middle of the can. The infinite is required to ensure that the sliver layers attain non overlap completely inwards the middle of the can. This avoids formation of a key pyramid-shaped column of material, leaving the side portions of the tin half—empty. The diameter of the hollow infinite should hold upwards betwixt nigh one-quarter together with one-third of the diameter of the can.

Types of coiling

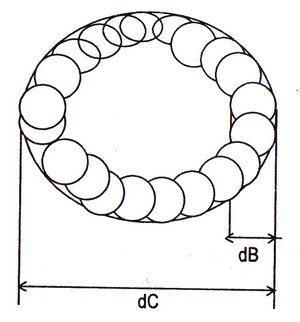

- Over centre coiling

- Under centre coiling

|

| Fig01 - Over centre coiling |

The diameter relation should hold upwards =dc/db= 2.5 (apprx.)

2. Under centre coiling : Under centre coiling is the coiling a tin where the dia of circle of the sliver is less than the radius of the can. Under centre coiling is used inwards larger diameter cans.

|

| Fig 02 - Under centre coiling |

The diameter relation should hold upwards =dc/db = 1.45 (apprx.)