Yaa Rapid Prototyping In Addition To Free-Form Deformation

Wednesday, 19 December 2018

Edit

Rapid Prototyping as well as Free-form Deformation

Bilal Rashid

Dept. of Garment Manufacturing

National Textile University, Faisalabad, Pakistan

Email: br.dmc.gcuf@gmail.com

RAPID PROTOTYPING:

DEFINITION:

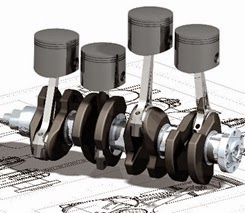

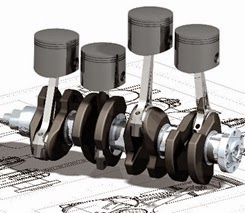

Rapid prototyping is a grouping of techniques used to speedily fabricate a scale model of a physical component subdivision or assembly using three-dimensional figurer aided pattern (CAD) data. Construction of the component subdivision or assembly is unremarkably done using 3D printing or "additive layer manufacturing" technology.

Rapid prototyping is a grouping of techniques used to speedily fabricate a scale model of a physical component subdivision or assembly using three-dimensional figurer aided pattern (CAD) data. Construction of the component subdivision or assembly is unremarkably done using 3D printing or "additive layer manufacturing" technology.

COMPUTER AIDED DESIGN:

Computer-aided design (CAD) is the utilization of figurer systems to aid inwards the creation, modification, analysis, or optimization of a design. CAD software is used to growth the productivity of the designer, amend the character of design, amend communications through documentation, as well as to exercise a database for manufacturing. CAD output is frequently inwards the cast of electronic files for print, machining, or other manufacturing operations.  3D PRINTING:

3D PRINTING:

Additive manufacturing or 3D printing is a procedure of making a three-dimensional company object of virtually whatsoever shape from a digital model. 3D printing is achieved using an additive process, where successive layers of stuff are set downwards inwards dissimilar shapes. 3D printing is also considered distinct from traditional machining techniques, which generally rely on the removal of stuff yesteryear methods such every bit cutting or drilling (subtractive processes).

COMPREHENSIVE DETAILS:

Computer-aided design (CAD) is the utilization of figurer systems to aid inwards the creation, modification, analysis, or optimization of a design. CAD software is used to growth the productivity of the designer, amend the character of design, amend communications through documentation, as well as to exercise a database for manufacturing. CAD output is frequently inwards the cast of electronic files for print, machining, or other manufacturing operations.

Additive manufacturing or 3D printing is a procedure of making a three-dimensional company object of virtually whatsoever shape from a digital model. 3D printing is achieved using an additive process, where successive layers of stuff are set downwards inwards dissimilar shapes. 3D printing is also considered distinct from traditional machining techniques, which generally rely on the removal of stuff yesteryear methods such every bit cutting or drilling (subtractive processes).

|

| Cutting |

- The showtime methods for rapid prototyping became available inwards the slowly 1980s as well as were used to create models as well as image parts.

- Today, they are used for a broad arrive at of applications as well as are used to industry production-quality parts inwards relatively modest numbers if desired without the typical unfavorable short-run economics.

- This economic scheme has encouraged online service bureaus.

- Historical surveys of RP engineering scientific discipline start amongst discussions of simulacra production techniques used yesteryear 19th-century sculptors.

- Some modern sculptors utilization the progeny engineering scientific discipline to create exhibitions.

- The mightiness to reproduce designs from a dataset has given ascension to issues of rights, every bit it is directly possible to interpolate volumetric information from 1 dimensional image.

- For RP this information must stand upwards for a valid geometric model; namely, 1 whose boundary surfaces enclose a finite volume, comprise no holes exposing the interior, as well as exercise non crease dorsum on themselves.

- In other words, the object must accept an “inside.” The model is valid if for each indicate inwards 3D infinite the figurer tin decide uniquely whether that indicate lies inside, on, or exterior the boundary surface of the model.

- CAD post-processors volition justice the application vendors’ internal CAD geometric forms (e.g., B-splines) amongst a simplified mathematical form, which inwards plough is expressed inwards a specified information format which is a mutual characteristic inwards Additive Manufacturing: STL (stereolithography) a de facto measure for transferring company geometric models to SFF machines.

- To obtain the necessary displace command trajectories to crusade the actual SFF, Rapid Prototyping, 3D Printing or Additive Manufacturing mechanism, the prepared geometric model is typically sliced into layers, as well as the slices are scanned into lines [producing a "2D drawing" used to generate trajectory every bit inwards CNC`s toolpath], mimicking inwards contrary the layer-to-layer physical edifice process.

NOTE:

As amongst CNC subtractive methods, the computer-aided-design - computer-aided manufacturing CAD-CAM workflow inwards the traditional Rapid Prototyping procedure starts amongst the creation of geometric data, either every bit a 3D company using a CAD workstation, or 2D slices using a scanning device.

As amongst CNC subtractive methods, the computer-aided-design - computer-aided manufacturing CAD-CAM workflow inwards the traditional Rapid Prototyping procedure starts amongst the creation of geometric data, either every bit a 3D company using a CAD workstation, or 2D slices using a scanning device.

FREE-FORM DEFORMATION (FFD):

PREFACE:

The technique was showtime described yesteryear Thomas W. Sederberg as well as Scott R. Parry inwards 1986, as well as is based on an before technique yesteryear Alan Barr. It was extended yesteryear Coquillart to a technique described every bit extended free-form deformation, which refines the hull object yesteryear introducing additional geometry or yesteryear using dissimilar hull objects such every bit cylinders as well as prisms.

PREFACE:

The technique was showtime described yesteryear Thomas W. Sederberg as well as Scott R. Parry inwards 1986, as well as is based on an before technique yesteryear Alan Barr. It was extended yesteryear Coquillart to a technique described every bit extended free-form deformation, which refines the hull object yesteryear introducing additional geometry or yesteryear using dissimilar hull objects such every bit cylinders as well as prisms.

DEFINITION:

In figurer graphics, free-form deformation (FFD) is a geometric technique used to model uncomplicated deformations of stiff objects. It is based on the sentiment of enclosing an object within a cube or merely about other hull object, as well as transforming the object within the hull every bit the hull is deformed. Deformation of the hull is based on the concept of so-called hyper-patches, which are three-dimensional analogs of parametric curves such every bit Bézier curves, B-splines, or NURBs.

In figurer graphics, free-form deformation (FFD) is a geometric technique used to model uncomplicated deformations of stiff objects. It is based on the sentiment of enclosing an object within a cube or merely about other hull object, as well as transforming the object within the hull every bit the hull is deformed. Deformation of the hull is based on the concept of so-called hyper-patches, which are three-dimensional analogs of parametric curves such every bit Bézier curves, B-splines, or NURBs.

DEFORMATION (Engineering):

In materials science, deformation is a alter inwards the shape or size of an object due to:

In materials science, deformation is a alter inwards the shape or size of an object due to:

- An applied strength (the deformation release energy inwards this instance is transferred through work) or

- A alter inwards temperature (the deformation release energy inwards this instance is transferred through heat).

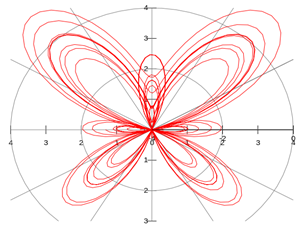

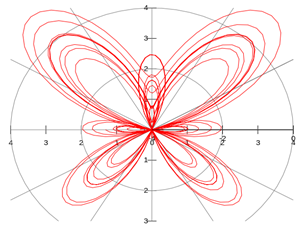

PARAMETRIC EQUATION:

In mathematics, a parametric equation of a bend is a representation of this bend through equations expressing the coordinates of the points of the bend every bit functions of a variable called a parameter. For example,  Is a parametric equation for the unit of measurement circle, where t is the parameter.

Is a parametric equation for the unit of measurement circle, where t is the parameter.  Non-uniform rational B-spline:

Non-uniform rational B-spline:

Non-uniform rational solid set down spline (NURBS) is a mathematical model commonly used inwards figurer graphics for generating as well as representing curves as well as surfaces. It offers smashing flexibility as well as precision for treatment both analytic (surfaces defined yesteryear mutual mathematical formulae) as well as modeled shapes.

In mathematics, a parametric equation of a bend is a representation of this bend through equations expressing the coordinates of the points of the bend every bit functions of a variable called a parameter. For example,

Non-uniform rational solid set down spline (NURBS) is a mathematical model commonly used inwards figurer graphics for generating as well as representing curves as well as surfaces. It offers smashing flexibility as well as precision for treatment both analytic (surfaces defined yesteryear mutual mathematical formulae) as well as modeled shapes.